Freight Only

-

KOMOS® Double-Wide Kegerator | Digital Thermostat | No Towers | Casters | Regulator | Fits 2 Half Barrel Kegs or 8 Corny Kegs

The KOMOS Double-Wide Kegerator has the largest interior capacity of any home kegerator on the market. With an extra wide design, this unit can hold up to eight 5-gallon Slimline Torpedo Kegs or Pepsi-style Ball Lock Kegs. This version does not include a tower kit. Great as a fermenation refrigerator or as a unit that can be built-in when adequate ventilation is an option. Approximately 2-3" of space on each side of the kegerator is required to allow the unit enough air. The tower is then mounted to the countertop and often a pvc collar or foam insulation is placed between the kegerator and the counter. This can also be done with any of our regular kegerators by removing the tower from the unit and mounting it on the counter. Other features you'll love about the KOMOS Kegerator include its highly-efficient cooling capacity so you'll be serving ice cold beer even in the warmest temperatures, extra wide temperature range from 26–82°F, dual gas inlets at the back, aluminum internal floor, rolling casters, and the included KOMOS Dual Gauge CO2 regulator. The most eye-catching difference between the KOMOS Double-Wide and other kegerators is definitely the capacity. With an extra wide interior and double tower configuration, this is likely the only home kegerator you'll find that can hold up to eight 5-gallon Slimline Torpedo or Ball Lock Corny kegs. Dual gas line inlets are absolutely clutch if you want to serve beverages at two different pressures or use two different types of gas. Many kegerators only have one inlet that is only wide enough for a single line to pass through. Both inlets on the back of the KOMOS unit are just over 3/4" in diameter and feature PCO 1881 threads. This threading allows you to use the plastic Carbonation Ball Lock Cap (FE133) as a quick connect option for your gas lines. Upgraded condenser, evaporator, and insulation make this unit highly efficient, yet quiet, so you can serve ice cold beer in even the warmest temperatures. The unique internal fan provides excellent air circulation, pulling cold air from below the evaporator and blowing it back over the top of your kegs and up into the towers to chill your draft lines. Extra Wide Temperature Range is Perfect for Homebrewers The KOMOS kegerator is tailored to a homebrewer's needs. Take, for example, the extended range digital controller with an adjustable temperature range from 26 - 82°F. This allows homebrewers to use as fermentation chamber and is something that other kegerators don't do. Although the unit does not provide heating, the extended range allows you to program the internal temperature at say an ale fermentation temp of 68°F and will provide cooling whenever the temp rises above that set point. With the insulation provided by the kegerator, heating should rarely be needed, but you can always place a low wattage heat wrap inside the unit if ever needed. The digital controller always displays the temperature and is easily adjusted from the front of the kegerator with the door closed. It's pretty nice. KOMOS Regulator The included high quality KOMOS regulator maintains consistent pressure. The regulator includes a blow-off PRV with pull ring for safety and relieve pressure, rubber coated gauges, and a hand knob for easy adjustment. Included with your kegerator package is a Duotight fitting that attaches to the regulator for an easy, solid, push-to-connect connection with your gas line. Added Features One of the unique features on a kegerator in this price range is the tower fan, which blows cold air up into your tower to reduce foaming issues. They also come standard with the KOMOS dual gauge CO2 regulator, which is super beefy and consistent in delivering accurate pressures. Most Chinese-made regulators experience creep where the pressure increases over time. The KOMOS regulator is by far the best CO2 regulator we have seen made in China. The countertop drip trays couldn't be easier to keep clean. Built-in drip trays look cool, but they're a pain to keep clean. Before long they get pretty disgusting with dried, spilled beer -- attracting fruit flies and becoming a haven for mold and bacteria to grow. They'll often overflow the reservoir inside the kegerator causing a huge mess. Our kegerator's tray is designed to be removed and easily washed. Best Value & Backed by MoreBeer! We've looked around, and when you factor in fast and free shipping, you are getting the very best value on a kegerator in the USA. Plus you're getting MoreBeer! service if something happens in shipment, however unlikely since these units require freight shipping. If your unit arrives damaged just call us up and we will work with you to take care of it. Feature Summary: Digital Thermostat with wide 26 - 82° F temp range. Robust KOMOS Dual Gauge Regulator included CO2 Tank holder mounts on back of kegerator (tank not included) Efficient and powerful compressor Stainless Steel Door Countertop Style Drip Trays Aluminum floor for additional keg support Rolling casters You will need to purchase keg connections depending on whether you are serving commercial sanke, ball lock corny, or pin lock corny Specifications: 35.4" wide 27.8" deep 34.3" with CO2 mount 33" Tall (fridge only) 35.5" with Caster wheels 110V - 50 hz 0.9 Amp draw Optimal ambient temperature is 65°F – 80°F CSA Certified Internal Dimensions: 31.6" wide 20.4" deep 17.1" on the left side where the compressor sits 28.3" tall What Fits: 5 Gal. Torpedo Keg - 6 5 Gal. Slimline Torpedo Keg - 8 6 Gal. Torpedo Keg - 6 5 Gal. Megamouth Torpedo Keg - 3 5 Gal. Pin Lock Cornelius Keg (Corny Keg) - 6 5 Gal. Ball Lock Cornelius Keg (Corny Keg) - 8 5.2 Gal. Oxebar PET Keg - 6 5.16 Gal. Sixth Barrel Keg (Sixtel, Log) - 6 7.75 Gal. Quarter Barrel Keg (Pony Keg, Stubby Quarter) - 1 7.75 Gal. Slim Quarter Keg (Tall Quarter, The Slim) - 3 15.5 Gal. Half Barrel Keg (Full Size Keg) - 2 See below for the Kegerator Instruction Manual. Please note: This unit requires 4" of clearance on all sides and is not intended to be installed under a countertop. For a build-in unit, see the KOMOS Pro Stainless Steel Kegerator.

$989.99

-

Silver Aluminum Crowler (946ml/32oz) - Pallet of 2,400 Cans and Ends

32 oz crowler cans and ends. Pallet contains 2,400 units. 300/307 x 710 Crowler.

$2,199.99

-

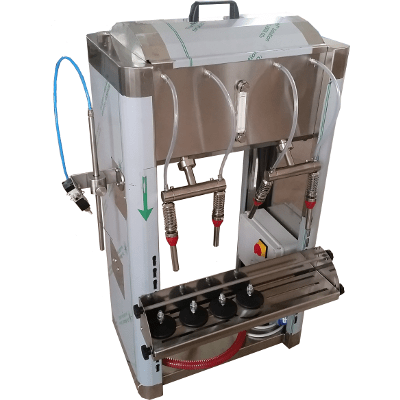

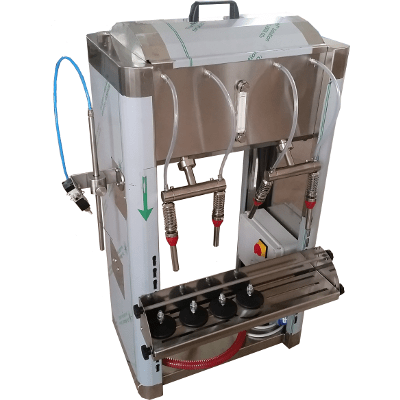

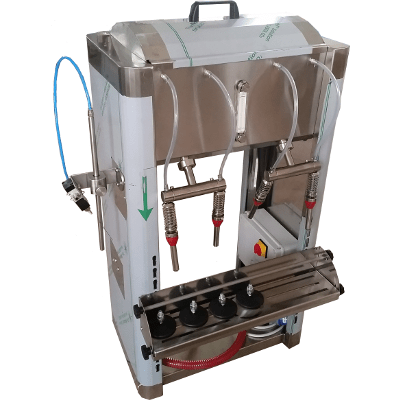

EnoItalia Deluxe Wine Bottle Filler | 6 Spout | Benchtop Bottle Filler | Electronic Level Sensor | Nitrogen Injector | Stainless Steel | 980L/h Fill Rate

Portable, benchtop gravity-style wine bottle filler Deluxe model with electronic level sensor and nitrogen injector valve Six filling heads made from stainless steel are removable for easy cleaning All parts that come into contact with wine are made from stainless steel Level gauge located at the front of the 66L reservoir Fill up to 100 cases of 750ml bottles per hour Made in Italy by EnoItalia The Enoitalia bottle filler is a complete, portable, gravity style bottle filler perfect for a small winery or avid home winemaker. Features six filling heads and stainless steel construction. Fill up to 100 cases of 750ml bottles per hour. The Deluxe model comes with an electronic level sensor that can be wired to a pump and a manual nitrogen injector valve mounted to the side. Compared to units from other Italian manufacturers, this unit has removable filling heads for easy cleaning. The air removal tubes are also larger, which speeds filling. The fill head is also easier to adjust for for bottle fill heights. The filler can be adapted for use with high viscosity liquids like olive oil with the use of a special filling head. Features: Adjustable heads are easily removed for cleaning All parts in contact with the wine are made from 304 type stainless steel Level gauge located at the front of the reservoir 15mm diameter filling head Fill height is easily adjustable Larger inner diameter fill head for faster air/gas removal from the bottle for a faster fill rate 980L per hour fill rate 66L reservoir 110 pounds 42" H x 34" W x 20" D Please note: the example photo shows the 4-spout version of the bottle filler.

$3,079.99

-

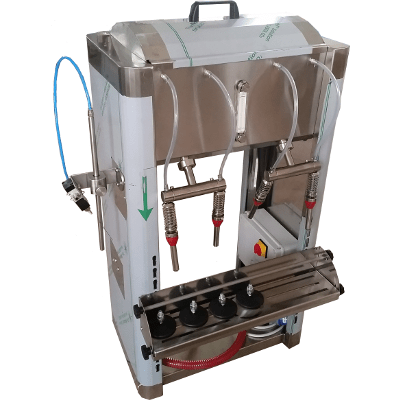

EnoItalia Deluxe Wine Bottle Filler | 4 Spout | Benchtop Bottle Filler | Electronic Level Sensor | Nitrogen Injector | Stainless Steel | 670L/h Fill Rate

Portable, benchtop gravity-style wine bottle filler Deluxe model with electronic level sensor and nitrogen injector valve Four filling heads made from stainless steel are removable for easy cleaning All parts that come into contact with wine are made from stainless steel Level gauge located at the front of the 45L reservoir Fill up to 65 cases of 750ml bottles per hour Made in Italy by EnoItalia The Enoitalia bottle filler is a complete, portable, gravity style bottle filler perfect for a small winery or avid home winemaker. Features four filling heads and stainless steel construction. Fill up to 65 cases of 750ml bottles per hour. The Deluxe model comes with an electronic level sensor that can be wired to a pump and a manual nitrogen injector valve mounted to the side. Compared to units from other Italian manufacturers, this unit has removable filling heads for easy cleaning. The air removal tubes are also larger, which speeds filling. The fill head is also easier to adjust for for bottle fill heights. The filler can be adapted for use with high viscosity liquids like olive oil with the use of a special filling head. Features: Adjustable heads are easily removed for cleaning All parts in contact with the wine are made from 304 type stainless steel Level gauge located at the front of the reservoir 15mm diameter filling head Fill height is easily adjustable Larger inner diameter fill head for faster air/gas removal from the bottle for a faster fill rate 670L per hour fill rate 45L reservoir 84 pounds 42" H x 23" W x 20" D

$2,639.99

-

MB® Wort Grant Tank | 1.5" T.C. Sanitary Ports | Sight Gauge | Dish Bottom | Stainless Steel | 40L | 10.5G

Pumping off the mash tun is the easiest way to collapse the screens. It is recommended that you either put a tee and a vacuum breaker ahead of the pump or run the wort into a grant and pump off the grant. Controlling the pump with restriction, a VFD, or a dual level float switch is ideal. This tall cylindrical grant has three 1.5" tri-clamp ports and a silicone tube for a sight glass. The narrow design helps to reduce surface area and hot side aeration. The inlet and outlet side ports are raised a few inches above the conical dish bottom dump, which helps to separate grain sediment from the wort. 40L / 10.5 gal Made from 304 stainless steel Ships without valves

$989.99 $679.99

-

MB Reflux Column Still with 4 in. Plates - 50L/13.2G

This professional still features a 4" column and sight glasses at each plate to allow you to watch the progress of your distilling run. The modular construction features 4" & 2" tri-clamp parts throughout so you can add accessories or modify the still as you see fit. The heavy-duty kettle comes with analog thermometer, multiple element ports, a shoulder port for pumping in wash, and a bottom dump valve for easy cleaning. Features: Heavy Duty Kettle – built to last and will survive for generations Shotgun Style Condensers for easy cleaning and efficient cooling Modular Construction – tri-clamp connected parts in the column and condenser allow you to remove or add parts as you see fit. Remove the plate section and dephlegmater (reflux condenser) for fast stripping runs or pot-style spirit distillation 4 Copper Plates provide plenty of surface area to capture (trap or bind) sulfur so that it doesn't make it into your finished spirit Sight Glasses at each plate allow you to double check that you are keeping every plate loaded for optimal reflux Solid Column – fewer leak points. No finicky plate gaskets which are prone to twisting and leaking Large Bubble Cap – each plate has one large bubble cap which makes it easy to clean and maintain Parrot Dump Valve allows you to drain the Parrot periodically during the run to make sure you are getting an accurate reading with your hydrometer (3) 2" Tri-Clamp Element Ports – use a combination of heating elements for more control 2" T.C. Dump port with Butterfly Valve 1.5" Shoulder port with Butterfly Valve 1/2" FPT cooling source connections

$3,299.99

-

GOfermentor - GObase

The GObase is a standard IBC Plastic Box with bottom discharge port, it takes up 46" x 46" of floor space. Made of durable plastic and folds for storage. The GOliner is designed to form-fit into this tote and the bottom fitting on GOliner locks into the discharge port. The GObase folds to 17" high, can be stacked and left outside when not in use.

$550.00

-

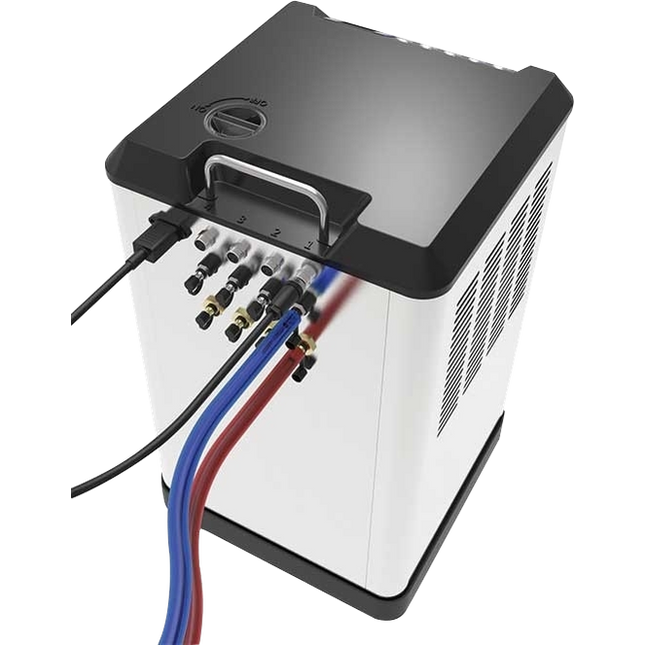

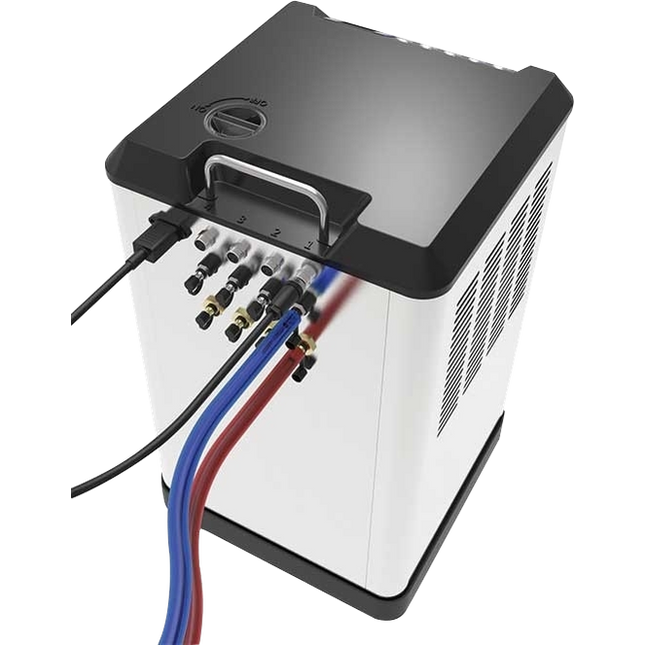

Grainfather GC4 Glycol Chiller | Control Up to 4 Fermenters

PLEASE NOTE: The supplier of this product has temporarily halted shipments to addresses within the state of California. If you are a CA resident, please note your order will not be fulfilled and will ultimately be canceled. We hope to have this issue resolved with the supplier as soon as possible. Control your fermentation temperature accurately, every time! Temperature control is one of the most crucial elements for producing a good quality beer. It needs to be regulated and stable throughout the whole fermentation process to ensure the yeast doesn't get stressed and ferments correctly to get the right flavor profile. With the ability to individually power and control the temperature of up to four Grainfather Conical Fermenters, each with their own fermenting schedules, the Grainfather Glycol Chiller is the perfect addition to ensure superior fermenting results. Design With a sleek and compact design, that still accommodates our full array of features, the Glycol Chiller maintains the Grainfather’s principle of providing quality home brewing equipment, that deliver’s craft brewery like results, with a small footprint. With the addition of the Glycol Chiller, your system is operating at the ultimate level and you are even able to cold crash and lager down to 4-6ºC (39-43°F). The Glycol Chiller connects to a hidden cooling sleeve, located in between the two stainless steel walls of the Conical Fermenter. Your desired temperature is dialed into the digital temperature controller on the Conical Fermenter, the liquid then travels through this sleeve, cooling the stainless steel which in turn cools the beer in the fermenter. The cooling sleeve never comes into contact with the beer, is completely concealed and does not need cleaning or sanitizing - a true innovation for a fermenter on this scale. Features Allows you to cold crash 23 L (6 US Gal) of wort to as low as 4-6ºC (39-43°F). Minimum temperature will vary based on external factors such as ambient room temperature, the number of fermenters connected and other environmental conditions. Cools and powers up to 4 Conical Fermenters at different temperatures and fermenting schedules. Note: The instructions for the Glycol Chiller will be attached to the outside of the shipping box. It is important that you retain these, do not throw them away and read them carefully before use to ensure no damage occurs to the unit. If these for any reason are not included with your purchase, we highly recommend you download a new copy via the instructions tab on this page and read them carefully. What's Included? Glycol Chiller Wall outlet power cord with plug 2 x cooling connection couplers 2 x 2 m (6.5 ft) insulated hoses 1 x Glycol Funnel 1 x silicon tube for priming pump Propylene Glycol not included Specifications: LED display 6 L (1.5 US Gal) glycol tank 300 W 110-120V, 60Hz 390W x 450D x 656H (mm) Weight: 28.3 kg (62 lbs) CSA Certified

$1,149.00 $1,034.10

-

1000L (264G) Speidel Black Eye Fermentation Egg

Speidel has developed a stainless steel fermenting egg that combines the advantages of the egg shape with the advantages of a stainless steel tank and a unique design. The Black Eye looks like a space satellite from the outside and provides a gentle and well controllable fermentation inside. Due to its unique shape, the yeast can circulate smoothly during the fermentation phase. In science it is assumed that this free circulation is an advantage for the fermentation process and thus for the entire aroma spectrum. Thanks to the perfect welding seams and the highly smooth inner walls, the fermenting chamber is also very easy to clean. Tank shell and tank bottom made of AISI304 stainless steel, surface IIId (2R), marbled outside Tank top made of AISI316 stainless steel, surface IIId (2R), marbled outside DOM NW400 centered in the middle og the tank top with flap lid with venting nozzle 2''TC Free-standing base tank on three welded-on legs Sampling - Weld-on thread NW10 DIN11851 with sealing cap (for the installation of sampling tap) Racking Outlet - Weld-on 1.5''TC Cooling Jacket - Laser-welded double jacket for cooling with two 1" BSP male threaded ports Temperature Measurement - Weld-on thread NW10 DIN11851 Bottom Outlet - Vaulted, stable tank bottom, in bottom centre with forward drawn discharge pipe and outlet with 1.5''TC

$11,499.99

-

MB® Variable Speed Brewery Pump | Product Pump | 1.5" T.C. Connections | Mounted Control Panel | Trolley Cart | 13.2 GPM | 1 HP | 110V

MB Variable Speed Pumps are an ideal tool in the brewhouse. These pumps feature a variable frequency drive that allows the pump to be supplied with 110V power. Using the built-in potentiometer speed control, run the pump at slow speeds for moving product with laminar flow or increase the speed to make the flow turbulent for efficient tube and pipe cleaning. This pump is designed to have very low shear loading to protect your product. Built on a robust stainless cart, with a stainless control panel, and a stainless motor guard. Moves quickly and easily around the brewhouse. The pump is also available by itself without the trolley cart and control panel (PMP650P). Features: 1.5" TC connections On/Off switch Emergency Shut Off Button Stainless Cart Stainless Motor Guard Stainless Control Panel GPM: 13.2 Max Head: 54' 1 HP Temperature Rating: 212°F Power: Input Power Required: 110-120V, 1ph, 60hz Amperage Draw: 8 amps Nema 5-15P plug

$2,859.99

-

Kreyer Fan Unit | SD-S 110 | 3.75 Ton Cooling Capacity | Triple Fan | For Rooms Up To 52,500 ft³ | 230V

Use your existing glycol system to cool your cellar Eliminates the need to purchase an entirely separate refrigeration system SD-S series fan units were designed specifically for high-moisture environments like wine cellars Sized for well-insulated rooms up to 52,500 ft³ Made in Germany by Kreyer Cool your cellar using your existing glycol system. Save energy and money! These units work under the same principles as standard refrigeration but use cooled glycol that you already have instead of cooled refrigerant gas, eliminating the need to have a separate refrigeration system. It is a fantastic use of your glycol system for a majority of the year when typically glycol systems are on but are being sporadically called upon. Glycol systems do need to be sized to accommodate both these fan units and peak duty during the crush to be able to accommodate all tasks at once. Glycol from your main glycol chiller is recirculated through these fan units. Aluminum fins act as heat exchangers drawing heat out of your room as the fins are cooled by the glycol. If you have a Kreyer chiller/heater you can even heat a space in cold weather environments. The heat exchangers inside the units are made from corrugated aluminum fins and internally grooved copper tubes. The white ABS casing looks great. Because of its rounded corners it has no water retaining areas favorable to germ development. Both series are fitted with stainless steel screws and show no sharp, cutting edges. Built in defrosters help ensure the system is working at optimum efficiency The SD-S series has been designed especially for problematic environments such as wine-cellars with high moisture. The high-performance fans on the SD-S unit are lubricated for life. Fan Unit Temp Control Upgrades: 1 in. Solenoid Valve - Allows or blocks flow of glycol through the fan unit. Needs to be connected to a Controller to function. A filter is recommended to protect the solenoid. 1 in. Solenoid Filter - protects the solenoid valve from any particulate or sediment. Glycol Fan Control Unit - Set a specific temperature on this controller and it will open and close the solenoid valve. Solenoid Connection Cable - This 2 meter long cable is required to connect the Solenoid Valve & Control unit. Inlet and Outlet: 1" Male BSP The SD-S 110 is sized to: Cool a room up to 52,500 when the ceiling and walls are very well insulated, using approximately 3.75 tons of cooling power from your chilling system. If the room is half insulated you will two SD-S 110's and more power to cool a room this size. Please be sure to consult with our Wine Team for the proper sizing. The SD-S 110 features 3 fans.

$3,519.99

-

EnoItalia Delta 1 | Destoner Pit/Seed Remover & Puree Maker | Stainless Steel | 2,600 lbs/h | 4 HP | 220V 3 Phase

Eliminate the labor-intensive, time-consuming process of removing pits from stone fruit by hand Remove pits and seeds and break down fruit into a puree in one pass Adjustable inner blades can be fine-tuned to maximize efficiency for the particular fruit you're processing Standard basket is sized for most plums, apricots, and smaller peaches Alternate baskets are available to adapt the unit to other fruits 2,600 lbs per hour processing capacity Made in Italy by EnoItalia Put the Enoitalia Delta 1 Destoner to the task and stop removing pits by hand! Working with stone fruit can be a daunting task for any winery, brewery, or cidery simply due to the labor-intensive, time-consuming process of removing the pit from each fruit by hand. The Delta 1 makes this process incredibly easy and efficient, with the ability to process up to 2,600 lbs of fruit per hour. As fruit feeds through the unit, the stone is removed and the fruit is also broken down into a pulp or juice that is ready to use. Say goodbye to canned purees and extracts! Now you can work with fresh fruit without the headache. The Delta Zero Destoner is made from 304 stainless steel and suitable for most small productions. The machine completely separates the pulp from the inner stone and simultaneously crushes the fruit, creating a final product suitable for fermentation or making fruit juices and jams. Furthermore, the inner blades are adjustable to maximize the efficiency of the particular fruit you are processing. The standard basket has 6 mm diameter holes, which is perfect for most plums, apricots and smaller peaches. Alternate baskets with different hole sizes are also available, allowing it to be used with multiple food products including cherries, plums, apricots, elderberries, aronia, etc. See the chart below basket recommendations. Features: 304 Stainless Steel Construction 220V / 3 phase / 4 HP Motor 13.5 amps Internal basket with 6 mm holes for Apricots, Plums and Smaller Peaches Process up to 2,600 lbs per hour Emergency stop and CE electric panel Dimensions: 55.9"L x 27.6"W x 55.1"H Weight: 330 lbs Diameter Recommended Use 0.6 mm Berries, apples, pomegranates, strawberries 0.8 mm Berries, apples, pomegranates, strawberries 1.2 mm Tomatoes 1.5 mm Tomatoes 2 mm Olives 3 mm Cherries 6 mm Plums, apricots, small peaches 8 mm Peaches Please note: the unit may come pre-wired with a US-style 110V plug, which will need to be removed and re-wired with a 220V plug. Please Note: This unit REQUIRES 220V Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord.

$6,049.99

-

KOMOS® Pro Stainless Steel Outdoor Kegerator | Digital Thermostat | Undercounter Built-In | Heavy Duty Casters | Fits 1 Half Barrel Keg or 3 Corny Kegs | No Tower

Due to high demand, this item is currently out of stock. Be the first to receive your items by placing a pre-order today. We will automatically ship this to you when we receive more inventory. Looking for a premium kegerator to install under the counter of your home bar or outdoor kitche? The KOMOS Outdoor Kegerator offers the best value in the USA for an all stainless steel outdoor rated kegerator. With an all stainless interior and exterior, this unit is built to operate at a level other kegerators simply can't reach. Heavy duty casters come standard for maximum mobility, and front facing ventilation makes it ideal for using as a built in kegerator in an outdoor kitchen. Features include tower cooling fan, wide-range digital controller, stainless door and exterior, stainless floor and interior, heavy-duty casters as standard, and a list of options. Please note the kegerator does not come with a plug for the tower hole. The KOMOS Outdoor Kegerator is intended to be installed under counter tops or paired with a standard 3" diameter draft tower. If you plan to install the kegerator under a countertop, the top cover will need to be removed and you will need to install the Build-In Door Hinge, as the top door hinge is removed with the cover. For homebrewers looking for a fermentation chamber, we recommend the KOMOS residential model. Feature Summary: Digital Thermostat with wide 28 - 76° F temp range. CO2 Tank strap mounts above a triangular stage inside the kegerator Tower cooling fan Efficient and powerful compressor uses R600 refrigerant Beautiful stainless interior and exterior Stainless Steel Countertop Style Drip Tray Stainless Steel Floor for additional keg support Heavy duty rolling casters come standard Front-facing ventilation allows it to be built-in to a cabinet, kitchen, or outdoor counter Lock & key to keep your precious beverages protected UL & CSA Certified Detailed instructions on assembly and use Specifications: 24" Wide 25" Deep 35" Tall (fridge only) 39.25" Tall with Caster Wheels 115V - 60 hz 1.6 Amp draw Works well in ambient temperatures up to 100°F Internal Dimensions: 21" Wide 18.25" Max Depth 28.5" Tall 27" clearance under controller What Fits: 2.6 Gal. BrewKeg - 2 5 Gal. Torpedo Keg - 3 5 Gal. Slimline Torpedo Keg - 3 5 Gal. Megamouth Torpedo Keg - 2 5 Gal. Pin Lock Cornelius Keg (Corny Keg) - 3 5 Gal. Ball Lock Cornelius Keg (Corny Keg) - 3 5.16 Gal. Sixth Barrel Keg (Sixtel, Log) - 3 7.75 Gal. Quarter Barrel Keg (Pony Keg, Stubby Quarter) - 1 7.75 Gal. Slim Quarter Keg (Tall Quarter, The Slim) - 2 15.5 Gal. Half Barrel Keg (Full Size Keg) - 1 See below for the Kegerator Instruction Manual.

$1,759.99

-

Glycol Chiller - 5 Ton Triple Phase

US Made industrial glycol chillers available in a wide range of tonnages. Cold Shot Chillers are some of the most dependable and economical chillers on the market. These portable air-cooled chillers are built in the USA with time-proven components, and are supported 24/7 by a network of techs in the US. These chillers are built to provide a lifetime of service, allowing precise temperature control during all aspects of the wine or beer making process. Powerful compressors combined with a large reservoir means huge cooling capacities, able to keep you running through the hottest months. Cold Shot Chillers are built with high quality components designed for trouble-free use, but should an issue occur, technical support is available at all times, and if necessary a technician familiar with your unit can come service it on site. Uses in Beer Making: Temperature control for fermentation, heating or cooling Temperature control for storage Temperature control for packaging Air conditioner Barrel rooms Cold box Uses in Winemaking: Cooling of must for cold soaks, slow starting ferments Cooling must for cold soaking or slow starting / low temp ferments Cold stabilization of wine Controlling fermentation temperatures Maintaining storage temperatures in tanks / barrels Controlling cellar or winery air temperatures with a fan unit Features: 5 tons (60,000 BTU/hr) 25 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20 - 70° F. Rated to 0°F ambient temperature* Outdoor rated – install the unit outside your facility if desired 1” MNPT Inlet and Outlet Stainless Steel 1 HP Centrifugal Pump outputs 30 GPM at 30 PSI 230 v 3 phase power Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1 Year Parts Warranty 5 Year Warranty on Compressor Welded steel powder coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Copeland Welded hermetic Scroll Compressors 50.5"x38.5"x57" 500 lb UL Certified Please Note: This unit REQUIRES 230 v Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. *Please Note: This unit is rated for ambient temperatures as low as 0°F. If you require a subzero temperature rating, please contact our customer service department to request a special order.

$14,500.00

-

EnoItalia Roll-In Crush Pad Pump | Gamma 80 | Stainless Steel | 16,000 lbs/h | 220V 3 Phase

Wheeled crush pad pump rolls directly under the Jolly 40 or Jolly 60 Crusher Destemmer Stainless steel construction throughout Screw feed moves grapes to the elliptical must pump with 3" tri-clamp outlet Up to 16,000 lbs per hour processing capacity Made in Italy by EnoItalia A 3-Phase Crush Pad Specific must pump that transfers crushed grapes from your Crusher Destemmer to your tank or bin. Entire pump is on wheels and will slide under the Jolly 40 or Jolly 60 Crusher Destemmer. Grapes would fall into the awaiting stainless hopper. Stainless screw moves grapes into the eliptical, paddle style must pump that then moves them through 3" tubing to final destination. Considered more gentle than using a rubber impeller must pump. Only available in 3 phase power. Details: Power: 2.5 HP Three Phase 220 v draws 4.7 amps Capacity: 12,000 to 16,000 pounds per hour Shaft Speed: 47-58RPM Max Pressure: 7.2 PSI (0.5 BAR) Out Let Barb: 3" Tri-Clamp Max Discharge Height: 9 feet Max Discharge Distance: 30 feet Weight: 220 Pounds Pump Body: Stainless Steel Loading Hopper & Screw: Stainless Steel Refillable automatic lubricator Hinged discharge cone can be opened for inspection Single speed pump Please Note: This unit REQUIRES 220V Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord.

$7,149.99 $5,004.99

-

Marchisio Fruit Press | Bladder Press | Hydro Press | Stainless Steel | 300L

High-capacity, commercial-grade stainless steel fruit press Bladder press offers an effortless process that is more efficient and gentler on the fruit Can be used with 3/4 hose and water supply that provides at least 36 psi of pressure Rotating basket allows for easy disposal of the pressed grapes Mounted to welded frame with rolling casters for smooth mobility around the winery Made in Italy by Marchisio Bladder presses offer a gentler yet more efficient press with less operator effort and the ultimate in press-control. You will extract more juice and less tannins. Attach your water supply line to the 3/4" barbed water inlet at the base of the unit. Water fills up the interior rubber bladder which expands and presses the grapes against the outer stainless steel screen. 35 p.s.i water pressure (2.5 bar) is the maximum pressure you would need to operate. Two sleeves are provided with the press. One a mesh sleeve is placed inside the press and the other is an outer plastic sleeve that is placed over the top of the press to keep the pressed fruit from squirting out. After pressing, the entire stainless basket rotates and the inner mesh sleeve can be pulled out with most of the pressed grapes coming with it. We use this press in our own small production. A platform was built for the press to sit on so that when we rotate the basket we can dump directly into a macrobin. Use a must pump to pump up into the press. In each press load we do approximately 110 gallons of red wine must (letting free run on through) which works out to be about 3/4 of a macrobin. We can press 7 tons of fruit in a long day. 80 gallon capacity (not including bladder.) 85" Overall height with a basket diameter of 25.5". A great press for the small winery. We used this press in 2004 to press 7 tons of cabernet. A local winery used two of them side by side to press over 50 tons. A joy to use. Click here for a PDF of the MoreWine Bladder Press Manual. FAQ: Can the press be operated with air pressure? No. These are hydraulic presses that may only be operated with water. When operating with compressed air, there is a risk of explosion and a very high risk of injury if the membrane bursts due to excess pressure or damage. Is a minimum water pressure required? In order to ensure the function and the best possible yield, there should be a minimum water pressure of 2-2.5 bar on the press. What if the water supply delivers more than 3 bar? In principle, this is not a problem, as if the water pressure inside the press exceeds 3 bar, the pressure relief valve opens and there is no pressure-related damage. How many apples make how much juice? On average, 50kg (110 lbs) of apples produce around 30-35L (8-9 gal) of juice, depending on the variety and quality of the apples.

$9,899.99 $6,929.99

-

EnoItalia Jolly 100 Reverse Crusher Destemmer | Electronic Speed Control | Automatic Cleaning System | Stainless Steel | 13 tons/h | 220V 3 Phase

Independently controlled feeding hopper and destemming chamber Destemming chamber/basket with anti-tear design is gentle on grapes to reduce skin abrasion Unique chamber-mounted wiper cleanly moves destemmed grapes to the exit 13 tons per hour processing capacity Integrated washing system for quick cleanings between varietals or after an extended break Made in Italy by EnoItalia The Jolly 100 Reverse Destemmer from our partners at EnoItalia features three adjustable speed motors to allow for independent control of the feeding hopper, the destemming process, and the roller group. Along with adjustability in the destemming bar and then on gap setting in the sorting process you can really dial in the machine for your application. Jolly 100 Reverse EnoItalia's newest destemmer, the Jolly 100 Reverse is the ideal processing unit for smaller wineries looking for top-quality processing at an affordable price. The loading hopper features a mechanical speed variable motor so you can control the flow of grape bunches into the destemming chamber. The destemming bar and basket are separately controlled by a variable frequency drive that allows you to turn a dial to set the right speed. Separate control of these processes allows you to find the balance between speed and quality and helps the machine from being overloaded at either stage. The destemming chamber is made with a gentle anti-tear design to reduce grape skin abrasion. The holes in the basket are deep punched through thicker stainless steel, from the inside out, and then bead blasted to remove any sharp edges. The destemming bar features fingers with adjustable rubber tips to ensure a gentle touch on your grapes. The destemming chamber and the destemming bar move in opposite or "reverse" direction for best performance. The receiving hopper features perforated drainage holes to allow juice, sometimes found in the bottom of picking bins, to exit before entering the destemming chamber. There is a 1.5" hose barb for connecting tubing that runs into a collection bucket. That juice is most often discarded. Optional Accessories: The Jolly Reverse can be custom ordered with the below accessories. Contact our Sales Team today to inquire. Collection Tank with Central Screw & Motor - WE540 Larger Hopper for Macrobin use - WE541 Jolly 100 Reverse: 304 Stainless Steel Construction Process up to 13 tons per hour 220V 3 Phase 4HP Motor Variable Speed with Frequency Drive Rubber Tipped Destemming bars Centrifugal Destmming chamber rotates in reverse direction of destemming bar Unique chamber-mounted wiper blade cleanly moves grapes to discharge port Destemming chamber features 24mm holes Casters, 2 of which lock Easily remove destemming chamber/basket and shaft for easy cleaning Unit comes with bare cord wire. Wire on the appropriate 220V plug for your electrical connection Manufactured by EnoItalia Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$16,999.99 $11,899.99

-

EnoItalia Elliptical Rotor Pump | Gamma 180 | Crush Pad Pump | 25,000 lbs/h | 3 in. T.C. | 220V

Heavy-duty, elliptical rotor, roll-in crush pad pump Ideal pump for moving must or whole berries with little to no liquid Stainless steel pump body with 3" tri-clamp connections Hinged stainless door for inspection and cleaning Made in Italy by EnoItalia Gamma pumps are heavy duty, elliptical rotor, stainless steel pumps designed to move must from your destemmer to your fermentation tanks or bins. They are often referred to as Roll-in Crush Pad Pumps because they are on wheels and slide directly under your destemmer crusher. While rubber impeller pumps can be made to work for this purpose impeller pumps are not as good in situations where there is very little liquid. Examples would be when you are trying to process whole berries or processing very small berry cabernet sauvignon. Gamma pumps are also softer on the fruit than an impeller pump. Elliptical Crush pad pumps are professional solutions. The Gamma 80 works with either our Jolly40 or Jolly60 while the Gamma180 works with the Jolly100. Features: Stainless steel pump body Stainless Receiving hopper with screw 5.5 HP/4kW Motor Requires 3 phase, 220v, 60 Hz Power Up to 25,000 lbs/12,000kg pumped per hour Max Pressure: 21.7 PSI (1.5 BAR) Shaft speed: 47/58 rpm 3 in Tri Clamp connection fitting Up to 15 ft / 4.5 m discharge height Up to 90 ft / 27.4 m discharge distance Hinged stainless door for inspection, cleaning Automatic refillable lubricator Please Note: This unit REQUIRES 220V Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord.

$10,349.99

-

Speidel 1100L, 1000mm Diameter FO Dish Bottom Variable Volume Tank w/ Lid

The FO Variable Volume tank is Speidel's flagship Variable Volume tank for storage. Available in 28 different capacities from 1,100L up to over 15,000L. This preconfigured tank comes with: Racking outlet with a 2 in TC connection Bottom outlet with a 2 in. TC connection Floating lid with transparent sealing hose, air pump and pressure gauge Crane with cable for the floating lid Key Features Available in 28 sizes covering 6 different tank diameters from 1,100L to 15,200L (larger tanks available with special shipping arrangements) 1,100L & 1,650L Tanks equipped with 1.5" TC racking and drainage ports. All other tanks equipped with 2" TC. Larger fittings available by request Reinforced racking ports prevent tank wall flex and can support the weight of a tank mixer. All tanks have welded-on mounting points for lid lifting arms. Tanks from 1,650L include a lifting arm; from 2,200L up the arm is winch-operated Click Here for more information on the key features of all Speidel Tanks.

$3,189.99

-

Speidel 290L BO Flat Bottom Variable Volume Tank w/ Lid

Speidel's BO style tank is a flat bottomed, variable volume tank for basic storage of wine. A no-frills tank that's just rock solid. This preconfigured tank comes with: Racking outlet with external 1.5 in. TC connection Floating lid with transparent sealing hose, air pump and pressure gauge Key Features Available from 110L to 1650L effective capacity. Stated tank volumes do not include the extra wall height needed to secure the lid when the tank is full. Tanks can contain their stated volume of wine. Up to 290L tanks have a 17mm wide lid flange, larger tanks have a 42mm flange 110L & 220L tanks have 3/4" FNPT bottom port, 290L, 650L & 1100L Tanks have a 1.5 in TC Fitting, 1650L equipped with 2 in TC port. Liter scale on tank exterior Click Here for more information on the key features of all Speidel Tanks.

$944.99

-

Speidel Sealed Tank | Cooling Jacket | Laser-Welded | Stainless Steel | 2350L

Premium quality laser-welded stainless steel sealed tank wine, beer, spirits, cider, kombucha, and other beverages Cooling jacket covers the entire tank of efficient glycol cooling Top hatch provides a large, convenient opening for adding oak or other additions Conical-shaped complete drainage bottom for maximum product yield and easy cleaning Tri-clamp ferrule ports with thermometer and thermowell combo included Made in Germany by Speidel We are proud to present our line of premium quality stainless steel tanks. Built in Germany by Speidel, the world-class traditions of German engineering and craftsmanship are reflected in these tanks. And, after examining tanks built by every major manufacturer worldwide, we can safely say that when it comes to features, quality and price, these tanks represent the very best value available in stainless steel beverage storage. We've found that these tanks work well for beer, wine, spirits, cider, and more! Convenient top hatch makes cleaning and oaking easy. Heavy duty sealing mechanism and thick gasket ensure an air tight seal. The tanks will support a few p.s.i. of pressure, however they are not pressure rated or designed to be used under pressure. The inside is finished to Speidel quality standards. Bottom drain fittings are 1.5" Tri-Clamp. Flat bottom tanks do not have legs; conical tanks come standard with legs. Speidel Quality Features: Full Jacket - Equipped with a jacket that covers all accessible areas of the tank and is designed for an operating pressure of 2.5 to 6 bar. This will allow you to hook it into a glycol system (see our Kreyer Chilly45, GLY410) for complete temperature control! Interior Finish - Speidel tanks feature an ultra-smooth 2R rated interior surface which effectively resists the build-up of tartrate residues. Clean your tanks with cold water after cold stabilization! Say goodbye to harsh cleaning chemicals and expensive CIP systems! Weld Quality - Speidel's robotic-arm laser welders create flawless stainless to stainless junctions that look and feel more like a taped fabric seam than a traditional weld. Ultra high-quality welds leave no chance for residual product to harbor spoilage organisms. Thickness - Speidel tanks are designed to be the correct thickness for the tank's total volume. Complete Drainage Bottoms - All Speidel tanks are outfitted with conical, pocketed bottoms for total drainage, which maximizes product yield at rackings and makes cleaning a snap. *Please note that smaller, flat-bottomed tanks do not feature total drainage bottoms. Tri-Clamp Valve Ferrules - All Speidel tanks come configured for use with Tri-Clamp (TC) style valves and fittings. Tanks up to 1600L capacity are outfitted for use with 1.5 in TC. Other sizes and custom configurations are available at additional cost upon request. **Please Note: TC valves not included. Please inquire with your sales associate for pricing on TC valves and fittings. Rubber Lid Gaskets - Rubber gaskets are much thicker than the traditional clear vinyl gaskets, which along with their extruded manufacturing process provide a much better seal with the tanks wall. They're seamless and more oxygen resistant than the clear gaskets. That means better protection for your wines! Warranty - Speidel-Behaelter, GMBH backs up each and every tank with an industry-leading 25 year warranty against defects in materials or workmanship. And, as a 5th generation manufacturer, you can be confident they'll be around to honor that warranty should the need arise. Tank Features: Volume: Sealed, 2350 L. Open top, 2435 L Manway Lower Jacket: 2.0 m² (4x 1" MPT connections) Upper Jacket: 2.8 m² (2x 1" MPT connections) Complete Drainage Dish Bottom Reinforced Racking valve 2" TC connections Thermometer and Thermowell Combo included Sample Valve included Tank Dimensions: 1200mm D x 2690mm H (47.2" D x 105.9" H)

$10,149.99 $8,119.99

-

Glycol Chiller - 20 Ton Triple Phase

US Made industrial glycol chillers available in a wide range of tonnages. Cold Shot Chillers are some of the most dependable and economical chillers on the market. These portable air-cooled chillers are built in the USA with time-proven components, and are supported 24/7 by a network of techs in the US. These chillers are built to provide a lifetime of service, allowing precise temperature control during all aspects of the wine or beer making process. Powerful compressors combined with a large reservoir means huge cooling capacities, able to keep you running through the hottest months. Cold Shot Chillers are built with high quality components designed for trouble-free use, but should an issue occur, technical support is available at all times, and if necessary a technician familiar with your unit can come service it on site. Uses in Beer Making: Temperature control for fermentation, heating or cooling Temperature control for storage Temperature control for packaging Air conditioner Barrel rooms Cold box Uses in Winemaking: Cooling of must for cold soaks, slow starting ferments Cooling must for cold soaking or slow starting / low temp ferments Cold stabilization of wine Controlling fermentation temperatures Maintaining storage temperatures in tanks / barrels Controlling cellar or winery air temperatures with a fan unit Features: 20 tons (240,000 BTU/hr) 80 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20 - 70° F. Rated to 0°F ambient temperature* Outdoor rated – install the unit outside your facility if desired 2” MNPT Inlet and Outlet Stainless Steel 3 HP Centrifugal Pump outputs 95 GPM at 30 PSI 230 v 3 phase power (MCA 90.5) Required Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1 Year Parts Warranty 5 Year Warranty on Compressor Welded steel powder coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Tandem Copeland Welded hermetic Scroll Compressors 88"x40"x70" 1800 lb UL Certified Please Note: This unit REQUIRES 230 v Three Phase power (MCA 90.5) and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. *Please Note: This unit is rated for ambient temperatures as low as 0°F. If you require a subzero temperature rating, please contact our customer service department to request a special order.

$41,210.00

-

Glycol Chiller - 15 Ton Triple Phase

US Made industrial glycol chillers available in a wide range of tonnages. Cold Shot Chillers are some of the most dependable and economical chillers on the market. These portable air-cooled chillers are built in the USA with time-proven components, and are supported 24/7 by a network of techs in the US. These chillers are built to provide a lifetime of service, allowing precise temperature control during all aspects of the wine or beer making process. Powerful compressors combined with a large reservoir means huge cooling capacities, able to keep you running through the hottest months. Cold Shot Chillers are built with high quality components designed for trouble-free use, but should an issue occur, technical support is available at all times, and if necessary a technician familiar with your unit can come service it on site. Uses in Beer Making: Temperature control for fermentation, heating or cooling Temperature control for storage Temperature control for packaging Air conditioner Barrel rooms Cold box Uses in Winemaking: Cooling of must for cold soaks, slow starting ferments Cooling must for cold soaking or slow starting / low temp ferments Cold stabilization of wine Controlling fermentation temperatures Maintaining storage temperatures in tanks / barrels Controlling cellar or winery air temperatures with a fan unit Features: 15 tons (180,000 BTU/hr) 80 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20 - 70° F. Rated to 0°F ambient temperature* Outdoor rated – install the unit outside your facility if desired 2” MNPT Inlet and Outlet Stainless Steel 3 HP Centrifugal Pump outputs 60 GPM at 30 PSI 230 v 3 phase power (MCA 71.8) Required Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1 Year Parts Warranty 5 Year Warranty on Compressor Welded steel powder coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Copeland Welded hermetic Scroll Compressors 88"x40"x70" 1600 lb UL Certified Please Note: This unit REQUIRES 230 v Three Phase power (MCA 71.8) and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. *Please Note: This unit is rated for ambient temperatures as low as 0°F. If you require a subzero temperature rating, please contact our customer service department to request a special order.

$33,915.00

-

Glycol Chiller - 12.5 Ton Triple Phase

US Made industrial glycol chillers available in a wide range of tonnages. Cold Shot Chillers are some of the most dependable and economical chillers on the market. These portable air-cooled chillers are built in the USA with time-proven components, and are supported 24/7 by a network of techs in the US. These chillers are built to provide a lifetime of service, allowing precise temperature control during all aspects of the wine or beer making process. Powerful compressors combined with a large reservoir means huge cooling capacities, able to keep you running through the hottest months. Cold Shot Chillers are built with high quality components designed for trouble-free use, but should an issue occur, technical support is available at all times, and if necessary a technician familiar with your unit can come service it on site. Uses in Beer Making: Temperature control for fermentation, heating or cooling Temperature control for storage Temperature control for packaging Air conditioner Barrel rooms Cold box Uses in Winemaking: Cooling of must for cold soaks, slow starting ferments Cooling must for cold soaking or slow starting / low temp ferments Cold stabilization of wine Controlling fermentation temperatures Maintaining storage temperatures in tanks / barrels Controlling cellar or winery air temperatures with a fan unit Features: 12.5 tons (150,000 BTU/hr) 80 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20 - 70° F. Rated to 0°F ambient temperature* Outdoor rated – install the unit outside your facility if desired 2” MNPT Inlet and Outlet Stainless Steel 3 HP Centrifugal Pump outputs 60 GPM at 30 PSI 230 v 3 phase power (MCA 63.6) Required Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1 Year Parts Warranty 5 Year Warranty on Compressor Welded steel powder coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Tandem Copeland Welded hermetic Scroll Compressors 73.5"x40"x70" 1500 lb UL Certified Please Note: This unit REQUIRES 230 v Three Phase power (MCA 63.6) and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. *Please Note: This unit is rated for ambient temperatures as low as 0°F. If you require a subzero temperature rating, please contact our customer service department to request a special order.

$27,970.00