Freight Only

-

EnoItalia Buffer Tank | Stainless Steel Collection Tank | 1.5" Tri-Clamp Outlet

Position under a wine press to separate solid material before pumping to your fermentation tank Remove seeds and oxygenate wine during a pump-over process Filter out seeds while moving wine from the fermentation tank to a holding tank A buffer tank or svinatore is used for several applications. During a press, during a pump-over and sometimes immediately following primary fermentation. The EnoItalia Buffer Tank is made entirely of 304 stainless steel and features a removable filter bed and 1.5" tri-clamp ferrule outlet. Mounted on caster wheels with a push cart handle for easy mobility from tank to tank around your winery. This unit is used under a press such as our 300L or 450L presses and also under red wine fermentation tanks in a pump-over process where the screen removes seeds and provides oxygenation during the initial parts of fermentation. Features: Tank and rolling cart frame made from stainless steel Removable filter made from stainless steel 1.5" T.C. outlet connection for pump Locking brake on all 4 casters 34 Gallon (130L) capacity Dimensions: 30.8" L x 25.75" W x 30.8" H (33.9" with wheels)

$1,319.99

-

TLC | SIS Brew | Powdered Alkaline Cleaner | Commercial Brewery Systems | 50 lb

Brewery Cleaning Tank and line cleaning Beer tap and line cleaning Soak cleaning of equipmentand parts TLC is a powdered, soft metal safe alternative to heavy caustic circulation cleaners. The special blend of alkaline builders, water conditioners, low foaming surfactant, and active oxygen are effective at removing a wide variety of organic and proteinaceous soils. Specifications: Color: White Fragrance: None pH Range: 11.5 - 12.2 Dilution: 1 - 4 oz. / gal. Density: 8.42 Please note: Intended for commercial use. Due to HAZMAT shipping restrictions, this product is required to ship via freight. It will ship directly from the manufacturer on its own pallet. If you order multiple SIS products, they will be condensed onto a single pallet, unless your order also contains sanitizers. Sanitizers must be shipped on a separate pallet from caustics and acids. HAZMAT items are not able to be returned.

$141.30

-

MB® 2 bbl Brite Tank | Single Shell | T.C. Sanitary Ports | All Fittings Included | Carbonation Stone | Full Length Sight Gauge | Passivated Ready to Use | American Engineered | Ships from USA

Designed by MB's in-house engineers with a focus on cleanability, ease of use, and durability Made from 304 stainless steel throughout with passivated 2B polished finished on the interior Sanitary tri-clamp connections from top to bottom with centered bottom drain, top vent/CO2 port with butterfly valve, and 4" hopping port—all fittings included! 15% extra headspace with a working volume of 2 bbl and max volume of 2.3 bbl True domed top and bottom with full length site gauge with sediment trap 2mm thick single shell design—click here for the 2 bbl Jacketed Brite Ships domestically from within the contiguous United States Available Ludicrous Coil for glycol-supplied temperature control MB brite tanks are made from 304 stainless steel and built to high quality standards. All of our brite tanks are pressured tested at the factory, feature 100% sanitary welds, and are backed by our one year warranty. Every brite tank features an average 15% headspace not stated in the volume, so for example, a 10 bbl brite really has 11.5 bbl of volume. The standard 1 & 2 bbl MB Brites feature a single shell design, sealed pressure gauge, and plunger-style sample valve to protect against infection. They also feature full length site gauges that extend below the bottom of the tank. This allows you to see when the tank is down to its last couple of pints, rather than its last couple of gallons. Please note: these units do not have a built-in cooling jacket and are intended to be used in a walk-in cold room for temperature control. Great Quality from MB MB is a brand that we dedicate to crafting and sourcing the equipment pro brewers need to make an exceptional product efficiently and consistently. Our brite tanks between 1 and 60 bbl are designed by our in-house team of engineers with decades of professional brewing experience. Focusing on cleanability, ease of use, and durability, we’ve made sure our tanks have the features that modern brewers expect when purchasing a new tank. While some discount dealers chase down bargain priced tanks from a string of manufacturers, we have maintained a long running relationship with a single manufacturer that ensures the quality of our products never wavers. Great Value from MoreBeer! Pro If you used MoreBeer! as a homebrewer, you may not know that MoreBeer! & MoreBeer! Pro combined is one of the largest brewing supply companies in the world with over 250,000 customers. We’ve seen countless homebrewers turn pro, and there’s nothing that makes us happier than being a part of that transition. As a privately owned brewing supply company that's been in business for over 25 years, we’ve established relationships with suppliers and manufacturers around the world and at every level of the industry. We get a great price and we pass that on to you. Features Include: 304 stainless steel construction True domed top and bottom Full length site gauge with sediment trap Pressure/Vacuum relief valve 1 Bar / 15 PSI Carbonation stone Sealed pressure gauge Analog temperature gauge Sample valve Center bottom tri-clamp drain Top vent/CO2 port with butterfly valve Pt100 Thermocouple interface Specifications: Grade 304 Stainless Steel 2mm thick single shell design Internal Finish: #2B Tank Height w/ Blowoff Pipe: 48.5" Tank Diameter w/ Fittings: 31" Empty Weight: 154 lbs Working Volume: 2 bbl Max Volume: 2.3 bbl Working Pressure: 1 Bar (14.5) All ports are 1.5" TC except 12" TC Dome Port and 4" TC Hopping Port Please Contact our Customer Service department at 1-800-600-0033 to assess shipment costs and place an order.

$2,419.99

-

EnoItalia Wine Plate Filter | 20x20 | 10 Plate | Stainless Rolling Cart | 280L/h | 220V Single Phase

Rolling cart plate filter for wine or oil Plates made from food-grade PPA Built-in ENOS 20 centrifugal pump Stainless ball valve and sample tap 280L/h wine filtering capacity Made in Italy by EnoItalia Made from AISI 304 stainless steel with 20x20 food-grade PPA filter plates (10 plates). Includes ENOS 20 pump with stainless body and impeller. Mounted to trolley cart with rolling casters. Features: Stainless ball valve Stainless sample tap Pressure gauge 220V single phase Input Voltage Required Wired with European-style 2-prong plug* Wine Capacity: 130-280 L/h (34-73 gal/h) Oil Capacity: 130 L/h (34 gal/h) Pump Barbs: 20 mm (0.78") Dimensions: 23.6" L x 19.7" W x 29.5" H Weight: 70.5 lbs *You will need a certified electrician to re-wire the unit with the appropriate 220V plug. 20 Plate unit pictured.

$1,599.99 $1,499.99

-

Euro 30 Wine Pump with Remote Control - USED REFURBISHED

Used – Refurbished This unit is used. It has been restored to working order. It will have cosmetic defects and show signs of previous use. It is still covered by our No Hassle Return Policy and 1 Year Warranty Policy. The perfect pump for moving wine from one vessel to the other. These Flexible Impeller Pumps are controlled by a Variable Frequency Drive, allowing for wine or juice transfers as fast as 20 gallons per minute, down to a complete stop. A sturdy Stainless Steel cart with nylon wheels allows for easy manueverability in the winery, and a lifetime of use. The pump can be controlled from the panel itself, or remotely via the wired controller, giving this workhorse even more flexibility. We worked for a year to develop this particular pump with Enoitalia of Italy. The value and price are really amazing. So much that we stopped making our own line of Chunky Pumps at the end of 2016. Enoitalia has been making pumps for decades and while they are excellent at destemmer crushers and other equipment, pumps are their core specialty. We will support the pump in the USA with common spare parts but we also have the backing and support of Enoitalia if anything was to go wrong. Stainless steel head with flexible rubber impeller Remote control with 40' cord included VFD allows for flow rate from 0 to 19.8 gpm 1.5" Tri-Clover inlet and outlet 220 v single phase Input voltage required (6.5 amp draw) Recommended temperature range: 40 - 150°F (5 - 65°C) Handy SS trolley cart for easy movement around the winery 1.5 HP Motor Self-priming Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug. Please Note: This pump will NOT come with fittings. It will have 1.5" Tri Clamp ferrules, and the appropriate fittings can be chosen from the "You Might Also Need" section below.

$2,969.99 $2,799.99

-

Speidel Jacketed Tank | Full Jacket | Laser-Welded | Stainless Steel | 625L

Premium quality laser-welded 304 stainless steel closed tank Made in Germany by Speidel and backed by a 25-year warranty Ideal for spirits and fermented beverages like wine, beer, cider, and kombucha. Ultra-smooth 2R interior finish allows for easy cleaning with cold water Outfitted with a 6-bar max cooling jacket for efficient glycol cooling 1.5” tri-clamp ports with two additional DIN ports for included thermometer/thermowell combo and sample valve The top lid provides a convenient opening for additions and the legs provide easy access to the bottom ports Vaulted complete drainage bottom for maximum product yield and easy cleaning We are proud to present these FD storage tanks made of premium quality 304 stainless steel. Built in Germany by Speidel and sold exclusively in the USA by MoreWine! Pro for over 20 years, the world-class traditions of German engineering and craftsmanship are reflected in these tanks. And, after examining tanks built by every major manufacturer worldwide, we can safely say that when it comes to features, quality, and price, these tanks represent the very best value available in stainless steel beer storage. Safely store small volumes of product in these beautiful tanks. The legs make accessing the ports easy and the convenient top hatch makes cleaning a dream when combined with the 2R interior finish. Heavy-duty sealing mechanism and gasket form a seal on top with a stainless steel lid equipped with a T.C. port for adding accessories or an airlock. The inside is finished to Speidel quality standards with flawless welds and a 2R finish. The tanks will support a few PSI of pressure, however, they are not pressure-rated or designed to be used under pressure. Tank Ports Tanks feature 1.5" T.C. outlets (1 on bottom for complete drainage, one in middle for racking arm, one on top for blowoff/airlock), and also two welded DIN fittings. One DIN port is equipped with an included sample valve and the other has an included thermometer and thermowell combination. The cooling jackets have two 1” NPT ports. Speidel Quality Features Full Jacket - These tanks are equipped with a max cooling jacket rated to 6-bar. This will allow you to hook it into a glycol system for complete temperature control. Interior Finish - Speidel tanks feature an ultra-smooth 2R interior surface which allows you to clean your tanks with cold water, without scrubbing. This saves significant labor costs. Weld Quality - Speidel's robotic-arm laser welders create flawless stainless-to-stainless junctions that look and feel more like a taped fabric seam than a traditional weld. Ultra high-quality welds leave no chance for residual products to harbor spoilage organisms. Warranty - Speidel and MoreWine! Pro back up each and every tank with an industry-leading 25-year warranty against defects in materials or workmanship. Thickness - Speidel tanks are on average around 25% thicker than Italian-manufactured tanks of the same general capacity and dimensions. Complete Drainage Bottoms - These tanks are outfitted with vaulted bottoms for total drainage, which maximizes product yield at racking and makes cleaning a snap. Tank Features: Full Volume of 625 L (165 gal) 1.5" T.C. Drain, Racking Port, and Lid outlet 8.5" Top hatch for easy cleaning and additions 2 X DIN10 Fittings w/ Sample Valve and Thermowell/Thermometer combo Tank Dimensions: 820mm D x 1661mm H (32.25" D x 60" H)

$4,069.99 $2,899.99

-

Speidel Jacketed Tank | Full Jacket | Laser-Welded | Stainless Steel | 525L

Premium quality laser-welded 304 stainless steel closed tank Made in Germany by Speidel and backed by a 25-year warranty Ideal for spirits and fermented beverages like wine, beer, cider, and kombucha. Ultra-smooth 2R interior finish allows for easy cleaning with cold water Outfitted with a 6-bar max cooling jacket for efficient glycol cooling 1.5” tri-clamp ports with two additional DIN ports for included thermometer/thermowell combo and sample valve The top lid provides a convenient opening for additions and the legs provide easy access to the bottom ports Vaulted complete drainage bottom for maximum product yield and easy cleaning We are proud to present these FD storage tanks made of premium quality 304 stainless steel. Built in Germany by Speidel and sold exclusively in the USA by MoreWine! Pro for over 20 years, the world-class traditions of German engineering and craftsmanship are reflected in these tanks. And, after examining tanks built by every major manufacturer worldwide, we can safely say that when it comes to features, quality, and price, these tanks represent the very best value available in stainless steel beer storage. Safely store small volumes of product in these beautiful tanks. The legs make accessing the ports easy and the convenient top hatch makes cleaning a dream when combined with the 2R interior finish. Heavy-duty sealing mechanism and gasket form a seal on top with a stainless steel lid equipped with a T.C. port for adding accessories or an airlock. The inside is finished to Speidel quality standards with flawless welds and a 2R finish. The tanks will support a few PSI of pressure, however, they are not pressure-rated or designed to be used under pressure. Tank Ports Tanks feature 1.5" T.C. outlets (1 on bottom for complete drainage, one in middle for racking arm, one on top for blowoff/airlock), and also two welded DIN fittings. One DIN port is equipped with an included sample valve and the other has an included thermometer and thermowell combination. The cooling jackets have two 1” NPT ports. Speidel Quality Features Full Jacket - These tanks are equipped with a max cooling jacket rated to 6-bar. This will allow you to hook it into a glycol system for complete temperature control. Interior Finish - Speidel tanks feature an ultra-smooth 2R interior surface which allows you to clean your tanks with cold water, without scrubbing. This saves significant labor costs. Weld Quality - Speidel's robotic-arm laser welders create flawless stainless-to-stainless junctions that look and feel more like a taped fabric seam than a traditional weld. Ultra high-quality welds leave no chance for residual products to harbor spoilage organisms. Warranty - Speidel and MoreWine! Pro back up each and every tank with an industry-leading 25-year warranty against defects in materials or workmanship. Thickness - Speidel tanks are on average around 25% thicker than Italian-manufactured tanks of the same general capacity and dimensions. Complete Drainage Bottoms - These tanks are outfitted with vaulted bottoms for total drainage, which maximizes product yield at racking and makes cleaning a snap. Tank Features: Full Volume of 525 L (138 gal) 1.5" T.C. Drain, Racking Port, and Lid outlet 8.5" Top hatch for easy cleaning and additions 2 X DIN10 Fittings w/ Sample Valve and Thermowell/ Thermometer combo Tank Dimensions: 820mm D x 1466mm H (32.25" D x 57.7" H)

$3,629.99 $2,309.99

-

Kreyer Fan Unit | SD-S 148 | 5.5 Ton Cooling Capacity | Quad Fan | For Rooms Up To 85,000 ft³ | 230V

Use your existing glycol system to cool your cellar Eliminates the need to purchase an entirely separate refrigeration system SD-S series fan units were designed specifically for high-moisture environments like wine cellars Sized for well-insulated rooms up to 85,000 ft³ Made in Germany by Kreyer Cool your cellar using your existing glycol system. Save energy and money! These units work under the same principles as standard refrigeration but use cooled glycol that you already have instead of cooled refrigerant gas, eliminating the need to have a separate refrigeration system. It is a fantastic use of your glycol system for a majority of the year when typically glycol systems are on but are being sporadically called upon. Glycol systems do need to be sized to accommodate both these fan units and peak duty during the crush to be able to accommodate all tasks at once. Glycol from your main glycol chiller is recirculated through these fan units. Aluminum fins act as heat exchangers drawing heat out of your room as the fins are cooled by the glycol. If you have a Kreyer chiller/heater you can even heat a space in cold weather environments. The heat exchangers inside the units are made from corrugated aluminum fins and internally grooved copper tubes. The white ABS casing looks great. Because of its rounded corners it has no water retaining areas favorable to germ development. Both series are fitted with stainless steel screws and show no sharp, cutting edges. Built in defrosters help ensure the system is working at optimum efficiency The SD-S series has been designed especially for problematic environments such as wine-cellars with high moisture. The high-performance fans on the SD-S unit are lubricated for life. Fan Unit Temp Control Upgrades: 1 in. Solenoid Valve - Allows or blocks flow of glycol through the fan unit. Needs to be connected to a Controller to function. A filter is recommended to protect the solenoid. 1 in. Solenoid Filter - protects the solenoid valve from any particulate or sediment. Glycol Fan Control Unit - Set a specific temperature on this controller and it will open and close the solenoid valve. Solenoid Connection Cable - This 2 meter long cable is required to connect the Solenoid Valve & Control unit. Inlet and Outlet: 1" Male BSP The SD-S 148 is sized to: Cool a room up to 85,000 cubic feet when the ceiling and walls are well insulated. Will use approximately 5.5 tons of cooling power from your chilling system. Please be sure to consult with our Wine team for proper sizing of a fan unit. This unit features 4 fans. Product Statistics Weight: 150lbs Dimensions: 82"L x 12"W x 18"H

$4,069.99

-

EnoItalia Delta Zero | Destoner Pit/Seed Remover & Puree Maker | Stainless Steel | 1,200 lbs/h | 1.5 HP | 220V Single Phase

Due to high demand, this item is currently out of stock. Be the first to receive your items by placing a pre-order today. We will automatically ship this to you when we receive more inventory. Eliminate the labor-intensive, time-consuming process of removing pits from stone fruit by hand Remove pits and seeds and break down fruit into a puree in one pass Adjustable inner blades can be fine-tuned to maximize efficiency for the particular fruit you're processing Standard basket is sized for most plums, apricots, and smaller peaches Alternate baskets are available to adapt the unit to other fruits 1,200 lbs per hour processing capacity Made in Italy by EnoItalia Put the Delta Zero to the task and stop removing pits by hand! Working with stone fruit can be a daunting task for any winery, brewery, or cidery simply due to the labor-intensive, time-consuming process of removing the pit from each fruit by hand. The Delta Zero makes this process incredibly easy and efficient, with the ability to process up to 1,200 lbs of fruit per hour. As fruit feeds through the unit, the stone is removed and the fruit is broken down into a puree that is ready to use. Say goodbye to canned purees and extracts! Now you can work with fresh fruit without the headache. The Delta Zero Destoner is made from 304 stainless steel and suitable for most small productions. The machine completely separates the pulp from the inner stone and simultaneously crushes the fruit, creating a final product suitable for fermentation or making fruit juices and jams. Furthermore, the inner blades are adjustable to maximize the efficiency of the particular fruit you are processing. The standard basket has 6 mm diameter holes, which is perfect for most plums, apricots and smaller peaches. Alternate baskets with different hole sizes are also available, allowing it to be used with multiple food products including cherries, plums, apricots, elderberries, aronia, etc. See the chart below basket recommendations. For processing larger stone fruit, such as peaches, we recommend the Delta 1 Destoner Pulper . Features: 304 Stainless Steel Construction 220V / single phase / 1.5 HP Motor 5 amps Internal basket with 6 mm holes for Apricots, Plums and Smaller Peaches Process up to 1,200 lbs per hour Emergency stop and CE electric panel Dimensions: 43.3 "L x 25.6" W x 51.2 "H Weight: 176 lbs Diameter Recommended Use 0.6 mm Berries, apples, pomegranates, strawberries 0.8 mm Berries, apples, pomegranates, strawberries 1.2 mm Tomatoes 1.5 mm Tomatoes 2 mm Olives 3 mm Cherries 6 mm Plums, apricots, small peaches 8 mm Peaches Please note: the unit may come pre-wired with a US-style 110V plug, which will need to removed and re-wired with a 220V plug.

$3,629.99

-

Marchisio Fruit Press | Bladder Press | Hydro Press | Stainless Steel | 450L

High-capacity, commercial-grade stainless steel fruit press Bladder press offers an effortless process that is more efficient and gentler on the fruit Can be used with any standard garden hose and water supply that provides at least 36 psi of pressure Rotating basket allows for easy disposal of the pressed grapes Mounted to welded frame with rolling casters for smooth mobility around the winery Made in Italy by Marchisio Bladder presses offer a gentler yet more efficient press with less operator effort and the ultimate in press-control. You will extract more juice and less tannins. Attach a standard garden hose to the included hose fitting. Water fills up the interior rubber bladder which expands and presses the grapes against the outer stainless steel screen. 35 p.s.i water pressure (2.5 bar) is the maximum pressure you would need to operate. Two sleeves are provided with the press. One a mesh sleeve is placed inside the press and the other is an outer plastic sleeve that is placed over the top of the press to keep the pressed fruit from squirting out. After pressing, the entire stainless basket rotates and the inner mesh sleeve can be pulled out with most of the pressed grapes coming with it. We use this press in our own small production. A platform was built for the press to sit on so that when we rotate the basket we can dump directly into a macrobin. Use a Must Pump (PMP565) to pump fermented grapes up into the press. 118 gallon capacity (not including bladder.) Click here for a PDF of the MoreWine Bladder Press Manual. FAQ: Can the press be operated with air pressure? No. These are hydraulic presses that may only be operated with water. When operating with compressed air, there is a risk of explosion and a very high risk of injury if the membrane bursts due to excess pressure or damage. Is a minimum water pressure required? In order to ensure the function and the best possible yield, there should be a minimum water pressure of 2-2.5 bar on the press. What if the water supply delivers more than 3 bar? In principle, this is not a problem, as if the water pressure inside the press exceeds 3 bar, the pressure relief valve opens and there is no pressure-related damage. How many apples make how much juice? On average, 50kg (110 lbs) of apples produce around 30-35L (8-9 gal) of juice, depending on the variety and quality of the apples.

$12,099.99 $9,074.99

-

Kreyer Chilly Max 50 | Glycol Chiller/Heater | 1.8 Ton | 21,840 BTU Cooling Capacity | 230V 3 Phase

Cooling & heating in one premium quality unit Control fermentation temperatures, cold-stabilize insulated tanks, or heat tanks during cold weather Fill from the exterior without the need to remove covers or panels Program and monitor temperatures via the digital controller Non-Return Kit installed as standard to prevent backflow when positioned below your tank jacket, heat exchanger, or piping system Four locking casters offer ease-of-mobility when moving the unit around the winery 1.8 Ton / 21,840 Btu cooling capacity 230V, 3 Phase power Made in Germany by Kreyer Cooling and Heating in one unit! Every Winemaker can appreciate the benefits of precise temperature control during all stages of production. This mobile unit allows you to easily control your ferment temperatures, heat your tanks during winter to expedite Malo-Lactic fermentation, or cold-stabilize your white wines. This unit can be used as portable unit in a larger winery or as a fixed system supplying a glycol loop in a smaller winery. Unit is used for heating or cooling but cannot supply both at the same time. Manufactured by Kreyer, the World's leading producers of wine-cooling equipment. Note: This unit runs off 230V 3 phase power. It will not run off 208V. Uses: Cooling of must for cold soaks, slow starting ferments Heating up must after a cold soak period Cold Stabilization of tartaric crystals Controlling fermenting temperatures through cooling or heating Maintaining storage temperatures in tanks/barrels Check out these features: Cools or Heats 1.8 Tons (21,840btu) of cooling power .85 Tons of heating power Can cool glycol/water bath down to -10C/14F or up to 42C/107F 230V 60Hz 3 phase supply voltage drawing 13.1 amps Rolls on four locking casters Sheet metal housing, electrolytic galvanized high surface quality, powder-coated and abrasion-resistant casing 7 Gallon Insulated Plastic glycol/water reservoir Easy to fill from outside Evaporator coil made of stainless steel High-quality Grundfos recirculation pump Built in pressure switch shuts down recirculation pump when not needed Digital Thermostat Lifting/Crane Hooks for transport All panels remove for easy access All units pass multiple tests prior to shipment German Engineering Controlled by compact PC boards with a temperature accuracy up to 0.1 degree Celsius. 33"L x 25"W x 31.5"T Unit has 1" Male BSP w/ 3/4" Female BSP inlet / outlet 6 Month Electrical Warranty 1 Year Mechanical Warranty CE Certified Please Note: This unit REQUIRES 230 v Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. Available in larger sizes. For additional product options click here.

$12,099.99

-

Speidel Variable Volume Tank | Cooling Jacket | Laser-Welded | Stainless Steel | 2200L

Variable capacity tank well-suited for fermentation, wine aging, kombucha, pickling, and other applications Floating lid can be positioned as needed to match the volume of the liquid you're working with Proprietary rubber lid gasket allows for a superior seal compared to traditional gaskets, providing better protection for your wine Cooling jacket covers the entire tank of efficient glycol cooling Hand crank lifting arm for lowering and lifting the floating lid Swinging manway door for easy removal of grape skins Made in Germany by Speidel We are proud to present our line of premium quality stainless steel tanks. Built in Germany by Speidel, the world-class traditions of German engineering and craftsmanship are reflected in these tanks. And, after examining tanks built by every major manufacturer worldwide, we can safely say that when it comes to features, quality and price, these tanks represent the very best value available in stainless steel wine storage. Speidel Quality Features: Cooling Jacket - This tank is equipped with a max coverage jacket that covers all accessible areas of the tank and is designed for an operating pressure of 2.5 to 6 bar. This will allow you to hook it into a glycol system (see our Kreyer Chilly45, GLY410) for complete temperature control! Interior Finish - Speidel tanks feature an ultra-smooth 2R rated interior surface which effectively resists the build-up of tartrate residues. Clean your tanks with cold water after cold stabilization! Say goodbye to harsh cleaning chemicals and expensive CIP systems! Weld Quality - Speidel's robotic-arm laser welders create flawless stainless to stainless junctions that look and feel more like a taped fabric seam than a traditional weld. Ultra high-quality welds leave no chance for residual product to harbor spoilage organisms. Thickness - Speidel tanks are designed to be the correct thickness for the tank's total volume. Manway - The "red wine" manway allows you to easily remove skins. Complete Drainage Bottoms - All Speidel tanks are outfitted with conical, pocketed bottoms for total drainage, which maximizes product yield at rackings and makes cleaning a snap. *Please note that smaller, flat-bottomed tanks do not feature total drainage bottoms. Tri-Clamp Valve Ferrules - All Speidel tanks come configured for use with Tri-Clamp (TC) style valves and fittings. Tanks up to 1600L capacity are outfitted for use with 1.5in TC. Other sizes and custom configurations are available at additional cost upon request. **Please Note: TC valves not included. Please inquire with your sales associate for pricing on TC valves and fittings. Rubber Lid Gaskets - The white rubber gaskets used by Speidel are much thicker than the traditional clear vinyl gaskets, which along with their extruded manufacturing process provide a much better seal with the tanks wall. They're seamless and more oxygen resistant than the clear gaskets. That means better protection for your wines! Warranty - Speidel-Behaelter, GMBH backs up each and every tank with an industry-leading 25 year warranty against defects in materials or workmanship. And, as a 5th generation manufacturer, you can be confident they'll be around to honor that warranty should the need arise. Tank Features: Volume: Sealed, 2237 L. Open top, 2344 L Variable Capacity Tank includes Floating lid and Heavy Duty White Rubber Gasket Large Manway Max Coverage Jacket: 3.2 m² (4x 1" MPT connections) Complete Drainage Dish Bottom Sight Gauge Lifting Arm with Winch Extended Legs - bottom dump port located 16" off the ground Reinforced Racking valve 2" TC connections Thermometer and Thermowell Combo included Sample Valve included Tank Dimensions: 1480mm D x 2009mm H (58.2" D x 79" H) With Lifting Arm: 2560mm H (100.7" H) Note: Over tightening the airlock / orange bulk head can cause it to crack. Only thread the airlock down until it feels snug. Do not over tighten.

$10,999.99 $7,699.99

-

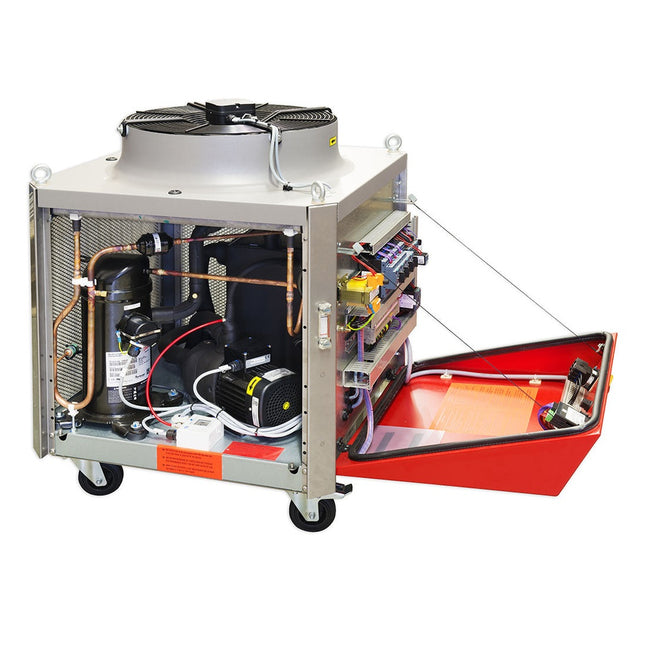

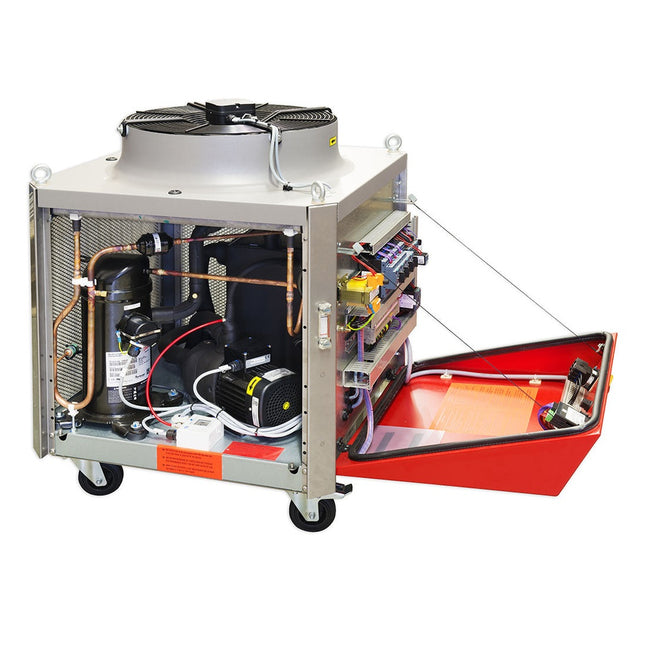

Glycol Chiller - 5 Ton Single Phase

US Made industrial glycol chillers available in a wide range of tonnages. Cold Shot Chillers are some of the most dependable and economical chillers on the market. These portable air-cooled chillers are built in the USA with time-proven components, and are supported 24/7 by a network of techs in the US. These chillers are built to provide a lifetime of service, allowing precise temperature control during all aspects of the wine or beer making process. Powerful compressors combined with a large reservoir means huge cooling capacities, able to keep you running through the hottest months. Cold Shot Chillers are built with high quality components designed for trouble-free use, but should an issue occur, technical support is available at all times, and if necessary a technician familiar with your unit can come service it on site. Uses in Beer Making: Temperature control for fermentation, heating or cooling Temperature control for storage Temperature control for packaging Air conditioner Barrel rooms Cold box Uses in Winemaking: Cooling of must for cold soaks, slow starting ferments Cooling must for cold soaking or slow starting / low temp ferments Cold stabilization of wine Controlling fermentation temperatures Maintaining storage temperatures in tanks / barrels Controlling cellar or winery air temperatures with a fan unit Features: 5 tons (60,000 BTU/hr) 25 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20 - 70° F. Rated to 0°F ambient temperature* Outdoor rated – install the unit outside your facility if desired 1” MNPT Inlet and Outlet Stainless Steel 1 HP Centrifugal Pump outputs 30 GPM at 30 PSI 230 v 1 phase power (MCA 40.8) Required Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1 Year Parts Warranty 5 Year Warranty on Compressor Welded steel powder coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Copeland Welded hermetic Scroll Compressors 50.5"x38.5"x57" 500 lb UL Certified Please Note: This unit REQUIRES 230 v Single Phase power (MCA 40.8) and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. *Please Note: This unit is rated for ambient temperatures as low as 0°F. If you require a subzero temperature rating, please contact our customer service department to request a special order.

$15,280.00

-

Glycol Chiller - 2 Ton Single Phase

US Made industrial glycol chillers available in a wide range of tonnages. Cold Shot Chillers are some of the most dependable and economical chillers on the market. These portable air-cooled chillers are built in the USA with time-proven components, and are supported 24/7 by a network of techs in the US. These chillers are built to provide a lifetime of service, allowing precise temperature control during all aspects of the wine or beer making process. Powerful compressors combined with a large reservoir means huge cooling capacities, able to keep you running through the hottest months. Cold Shot Chillers are built with high quality components designed for trouble-free use, but should an issue occur, technical support is available at all times, and if necessary a technician familiar with your unit can come service it on site. Uses in Beer Making: Temperature control for fermentation, heating or cooling Temperature control for storage Temperature control for packaging Air conditioner Barrel rooms Cold box Uses in Winemaking: Cooling of must for cold soaks, slow starting ferments Cooling must for cold soaking or slow starting / low temp ferments Cold stabilization of wine Controlling fermentation temperatures Maintaining storage temperatures in tanks / barrels Controlling cellar or winery air temperatures with a fan unit Features: 2 tons (24,000 BTU/hr) 25 Gallon Stainless Steel Reservoir Tank with Lid This Low Temp Model has a leaving fluid temperature range of 20 - 70° F. Rated to 0°F ambient temperature* Outdoor rated – install the unit outside your facility if desired 1” MNPT Inlet and Outlet Stainless Steel 1 HP Centrifugal Pump outputs 30 GPM @ 30 PSI 230 v Single Phase power (MCA 21.3) Required Casters Included (two swivel locking and two fixed) Large Reservoir easily filled from outside, and level indicated with sight gauge 1 Year Parts Warranty 5 Year Warranty on Compressor Welded steel powder coated frame and full metal cabinet with copper piping connections Digital Temperature controller with Self-Diagnostic control system Rugged Protection, while still easy to maintain and Wash Down High Flow Pump, Long Life, Dependable units! Stainless Steel Plate Evaporators Vacuum brazed with Copper Dependable Copeland Welded hermetic Scroll Compressors 42"x32.5"x51.5" 350 lb UL Certified Please Note: This unit REQUIRES 230 v Single Phase power (MCA 21.3) and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. *Please Note: This unit is rated for ambient temperatures as low as 0°F. If you require a subzero temperature rating, please contact our customer service department to request a special order.

$11,825.00

-

Tenco Pneumatic Bottle Corker | Benchtop Wine Bottle Corker | 400 Bottles/Hour - Refurbished

Cork up to 400 bottles per hour with the StarCap pneumatic corking machine Air-driven semi-automatic bottle corker makes the process efficient and effortless Compatible with all natural, agglomerated, collated, and 1+1 agglomerated corks Air pressure regulator with manometer allows for pressure adjustments depending on the cork being used Made in Italy by Tenco The StarCap semi-automatic bottle corker from Tenco provides excellent corking capacity for small wineries or avid home vintners. It is pneumatically driven so you will need an air compressor to operate the corking action. Wine corks are manually inserted into the cone then, by pressing the two start buttons, the cork is inserted into the bottle neck of the wine bottle by slightly compressing the cork. The StarCap machine guarantees perfect integrity, doesn’t create seems on the surface, and doesn’t affect the material in any way. Our customers who love this corker are primarily using it because using a traditional floor corker to cork hundreds of bottles of wine is physically taxing... unless you have a lot of help. If you have a lot of help on bottle day running two floor corkers is approximately the same speed. Specifications: Capacity: 400 bottles/hour Power: Compressed Air Air Connection: Push-to-connect fitting for 8mm (5/16") OD rigid tubing Can be converted to barb with 1/4" BSPP male threaded adapter Max Diameter: 25 mm Max Height: 45 mm Minimum Bottle Height: 200 mm Max Bottle Height: 370 mm Compatible Corks: Natural, agglomerated, collated, 1+1 agglomeration

$2,309.98 $1,928.69

-

Wine Fermenter - 44 Gallon FDA Plastic

Made from FDA-approved, food-grade plastic, these fermenters are ideal for the initial ferment of wine, especially red wines. The 44 Gallon container is too large to ship via Fedex and must ship freight. Usually this is only feasible when combined with equipment we are already shipping for you.

$79.99

-

EnoItalia Wine Bottle Filler | 6 Spout | Stainless Trolley Cart | Electronic Level Sensor | Integrated Pump | 980L/h Fill Rate | 110V

The Enoitalia bottle filler is a complete, portable, gravity style bottle filler perfect for a small winery. Features six filling heads and stainless steel construction. This a complete bottle filling solution that comes on cart and includes built in pump, electronic float switch, and electric valve. As the wine level drops in the reservoir the pump is turned on to refill. Electric valve keeps wine from being siphoned back out of reservoir. Fill up to 100 cases of 750ml bottles per hour. If you do not have the human power to keep up you can use 4 heads at a time so there is no disadvantage to getting a 6 head filler vs a 4 head filler. We only offer the 6 head filler in this model because the price is very similar between 4 and 6. Unlike units from other Italian manufacturers, this unit has removable filling heads for easy cleaning. The air removal tubes are also larger which speeds filling. The fill head is also easier to adjust for bottle fill heights. The filler can be adapted for use with high viscosity liquids like olive oil with the use of a special filling head. Features: Adjustable heads are easily removed for cleaning All parts in contact with the wine are made from 304 type stainless steel Level gauge located on the side of the reservoir Built-in rubber impeller pump with 1.5" T.C. inlet/outlet Rubber impeller pump built-in Electronic float control Electronic shut-off valve On 4" casters with brake 15mm diameter filling head Fill height is easily adjustable Larger inner diameter fill head for faster air/gasremoval from the bottle for a faster fill rate 980L per hour fill rate 55L reservoir Can fill bottles up to 22" tall 200 pounds 71" T x 34"w x 26" D 110V Please note: The integrated pump is hardwired into the panel. It cannot be disconnected and used separately as it appears in the photo.

$3,849.99

-

Briess CBW® Sparkling Amber | Concentrated Brewers Wort | Liquid Malt Extract | LME | 11 SRM

Sparkling Amber is an excellent choice for Pale Ales, Reds, Ambers, and darker beers including Stouts and Porters Can be used as 100% of your fermentable sugar in extract brewing Add for color correction, boost gravity, or improve head retention in all grain brewing Briess Malt & Ingredients has had a focus on quality and innovation for more than 140 years, with all of their products being made in the U.S.A. Concentrated Brewers Wort (CBW) Liquid Malt Extract (LME) from Briess. Briess CBW malt extracts get all of their color and flavor from base and specialty malts, never through additional boiling. CBW malt extracts are unhopped and nondiastatic for flexible, creative brewing. Sparkling Amber LME: 100% pure malt barley extract made from 100% malt and water. Typical Analysis: Color (8° Plato): 11 SRM Fermentability: 75% Solids: 79%

$14.99 $11.99

-

MB® 1 bbl Brite Tank | Jacketed | T.C. Sanitary Ports | All Fittings Included | Carbonation Stone | Full Length Sight Gauge | Passivated Ready to Use | American Engineered | Ships from USA

Designed by MB's in-house engineers with a focus on cleanability, ease of use, and durability Made from 304 stainless steel throughout with passivated 2B polished finished on the interior Sanitary tri-clamp connections from top to bottom with centered bottom drain, top vent/CO2 port with butterfly valve, and 4" hopping port—all fittings included! 20% extra headspace with a working volume of 1 bbl and max volume of 1.2 bbl True domed top and bottom with full length site gauge with sediment trap 1.5 mm thick dimple welded cooling jacket—click here for the 1 bbl Single Shell Brite Ships domestically from within the contiguous United States These heavy-duty Beer Tanks are purpose built for longevity, quality, and cost effectiveness, and boast a hefty list of quality features to ease the brewing process. MB brite tanks are made from 304 stainless steel and built to high quality standards. All of our brite tanks are pressured tested at the factory, feature 100% sanitary welds, and are backed by our one year warranty. Every brite tank features an average 15% headspace not stated in the volume, so for example, a 10 bbl brite really has 11.5 bbl of volume. The 1 & 2 bbl Jacketed Brites feature sealed pressure gauge, and plunger-style sample valve to protect against infection. They also feature full length site gauges that extend below the bottom of the tank. This allows you to see when the tank is down to its last couple of pints, rather than its last couple of gallons. Great Quality from MB MB is a brand that we dedicate to crafting and sourcing the equipment pro brewers need to make an exceptional product efficiently and consistently. Our brite tanks between 1 and 60 bbl are designed by our in-house team of engineers with decades of professional brewing experience. Focusing on cleanability, ease of use, and durability, we’ve made sure our tanks have the features that modern brewers expect when purchasing a new tank. While some discount dealers chase down bargain priced tanks from a string of manufacturers, we have maintained a long running relationship with a single manufacturer that ensures the quality of our products never wavers. Great Value from MoreBeer! Pro If you used MoreBeer! as a homebrewer, you may not know that MoreBeer! & MoreBeer! Pro combined is one of the largest brewing supply companies in the world with over 250,000 customers. We’ve seen countless homebrewers turn pro, and there’s nothing that makes us happier than being a part of that transition. As a privately owned brewing supply company that's been in business for over 25 years, we’ve established relationships with suppliers and manufacturers around the world and at every level of the industry. We get a great price and we pass that on to you. Features Include: 304 stainless steel construction Includes a glycol jacket which is dimple welded and 1.5 mm thick True domed top and bottom Full length site gauge with sediment trap Pressure/Vacuum relief valve 1 Bar / 15 PSI Carbonation stone Sealed pressure gauge Analog temperature gauge Sample valve Center bottom tri-clamp drain Top vent/CO2 port with butterfly valve Pt100 Thermocouple interface Specifications: Grade 304 Stainless Steel Internal Finish: #2B Tank Height w/ Fittings: 48" Tank Diameter: 23.6" Empty Weight: 176 lbs Working Volume: 1 bbl Max Volume: 1.2 bbl Working Pressure: 1 Bar (14.5) All ports are 1.5" TC except for 10" TC Dome Port and 4" TC Hopping Port and 1/2" NPT Glycol Ports Please note: the 2 bbl unit is shown in the example photo. Please Contact our Customer Service department at 1-800-600-0033 to assess shipment costs and place an order.

$3,079.99

-

Farro Glass | Premium Wine Bottles | Large Format Magnum Wine Bottle | Champagne | Dark Green | 1.5L | Case of 6

Large format Magnum wine bottle with the same capacity as 2 standard bottles of wine Champagne style bottle made from thicker glass designed to hold highly carbonated sparkling wines Dark green glass color offers superior light protection compared to light green or clear bottles Farro Glass offers a full lineup of the most essential and commonly used bottles in winemaking Thicker and heavier than your standard wine bottle, these champagne style bottles are designed to hold high pressure beverages like sparkling wine. They are both corkable and cappable with a 29 mm crown cap. This large format 1.5 liter bottle holds the equivalent volume of 2 standard bottles of wine. Volume: 1.5L Style: Champagne / Sparkling Use: Sparkling Wine Color: Dark Green Finish: Cork / Crown Cap Neck Opening: 17.5 Bottom: Punted Case QTY: 6 Our Farro Glass Wine Bottles offers a full lineup of the most essential and commonly used bottles in winemaking. We scoured the world to find a bottle source that could provide a quality product consistently and at a fair price that we can pass on to our customers. If you've been searching for reasonably priced bottles that are reliably in stock, look no further.

$36.49

-

BevBright Stainless Steel Lenticular Filter Housing | 12" | 1 High

Due to high demand, this item is currently out of stock. Be the first to receive your items by placing a pre-order today. We will automatically ship this to you when we receive more inventory. Lenticular filters employ a filtering process similar to plate filters but are significantly easier to use A sealed system ensures there is no dripping/leakage, unlike what occurs with plate filters Filters are stacked within cartridges, making loading and replacement much simpler than a plate filter Housings can be loaded with as few as one filter cartridge with the use of optional center posts BevBright Lenticular Filter Housings streamline the filtration process, making it as effective as traditional plate filters but with greater ease of use. Their user-friendly design ensures that anyone, from experienced professionals to beginners, can operate them effortlessly. The setup is straightforward and without the complexities associated with plate filters. One of the key benefits of lenticular filters is their sealed system. This design prevents dripping and leakage, guaranteeing airtight integrity and ensuring that your liquids remain protected and uncontaminated. Filters stack neatly within the housing, and loading or replacing them is simple. There are no intricate assemblies required. Whether performing maintenance or adjusting filtration levels, the process is seamless and hassle-free. Optional center posts allow the housings to accommodate as few as one filter cartridge, providing flexibility for various filtration needs, from large-scale production to small-batch operations. Choose BevBright stainless steel lenticular filter housings for a filtration solution that is efficient, reliable, and easy to use. Each unit comes complete with hardware and instructions, ready for immediate use. Made from 304 Stainless Steel Polish: Ra<0.4um Hardware Included: (2) 1.5" T.C. Pressure Gauges (2) 1.5" T.C. Butterfly Valves (1) 1.5" T.C. Tee (1) Top Relief Valve (1) 1.5" T.C. Drain Valve Clamps & Gaskets Please Note: Example images of the 12" / 3 High Lenticular Housing shown here. Updated images coming soon.

$2,969.99

-

Kreyer Chilly Max 50 | Glycol Chiller/Heater | 1.8 Ton | 21,840 BTU Cooling Capacity | 230V Single Phase

Cooling & heating in one premium quality unit Control fermentation temperatures, cold-stabilize insulated tanks, or heat tanks during cold weather Fill from the exterior without the need to remove covers or panels Program and monitor temperatures via the digital controller Non-Return Kit installed as standard to prevent backflow when positioned below your tank jacket, heat exchanger, or piping system Four locking casters offer ease-of-mobility when moving the unit around the winery 1.8 Ton / 21,840 Btu cooling capacity 230V, Single Phase power Made in Germany by Kreyer Cooling and Heating in one unit! Every Winemaker can appreciate the benefits of precise temperature control during all stages of production. This mobile unit allows you to easily control your ferment temperatures, heat your tanks during winter to expedite Malo-Lactic fermentation, or cold-stabilize your white wines. This unit can be used as portable unit in a larger winery or as a fixed system supplying a glycol loop in a smaller winery. Unit is used for heating or cooling but cannot supply both at the same time. Manufactured by Kreyer, the World's leading producers of wine-cooling equipment. Note: This unit runs off 230V single phase power. It will not run off 208V. Uses: Cooling of must for cold soaks, slow starting ferments Heating up must after a cold soak period Cold Stabilization of tartaric crystals Controlling fermenting temperatures through cooling or heating Maintaining storage temperatures in tanks/barrels Check out these features: Cools or Heats 1.8 Tons (21,840btu) of cooling power .85 Tons of heating power Can cool glycol/water bath down to -10C/14F or up to 42C/107F 230V 60Hz Single phase Power supply Required Rolls on four locking casters Sheet metal housing, electrolytic galvanized high surface quality, powder-coated and abrasion-resistant casing 7 Gallon Insulated Plastic glycol/water reservoir Easy to fill from outside Evaporator coil made of stainless steel High-quality Grundfos recirculation pump Built in pressure switch shuts down recirculation pump when not needed Digital Thermostat Lifting/Crane Hooks for transport All panels remove for easy access All units pass multiple tests prior to shipment German Engineering Controlled by compact PC boards with a temperature accuracy up to 0.1 degree Celsius. 33"L x 25"W x 31.5"T Unit has 1" Male BSP w/ 3/4" Female BSP inlet / outlet 6 Month Electrical Warranty 1 Year Mechanical Warranty CE Certified Please Note: This unit REQUIRES 230 v Single Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. Available in larger sizes. For additional product options click here.

$12,949.99

-

Kreyer Chilly Max 90 | Glycol Chiller/Heater | 3 Ton | 36,000 BTU Cooling Capacity | 230V 3 Phase

Due to high demand, this item is currently out of stock. Be the first to receive your items by placing a pre-order today. We will automatically ship this to you when we receive more inventory. Cooling & heating in one premium quality unit Control fermentation temperatures, cold-stabilize insulated tanks, or heat tanks during cold weather Fill from the exterior without the need to remove covers or panels Program and monitor temperatures via the digital controller Non-Return Kit installed as standard to prevent backflow when positioned below your tank jacket, heat exchanger, or piping system Four locking casters offer ease-of-mobility when moving the unit around the winery 3 Ton / 36,000 Btu cooling capacity 230V, 3 Phase power Made in Germany by Kreyer Cooling and Heating in one unit! Every Winemaker can appreciate the benefits of precise temperature control during all stages of production. This mobile unit allows you to easily control your ferment temperatures, heat your tanks during winter to expedite Malo-Lactic fermentation, or cold-stabilize your white wines. This unit can be used as portable unit in a larger winery or as a fixed system supplying a glycol loop in a smaller winery. Unit is used for heating or cooling but cannot supply both at the same time. Manufactured by Kreyer, the World's leading producers of wine-cooling equipment. Note: This unit runs off 230V 3 phase power. It will not run off 208V. Uses: Cooling of must for cold soaks, slow starting ferments Heating up must after a cold soak period Cold Stabilization of tartaric crystals Controlling fermenting temperatures through cooling or heating Maintaining storage temperatures in tanks/barrels Check out these features: Cools or Heats 3 Tons (36,000btu) of cooling power (larger Chilly Max's are available) .85 Tons of heating power Can cool glycol/water bath down to -10C/14F or up to 42C/107F 230v 60Hz 3 phase supply voltage drawing 19.3 amps Rolls on four locking casters Sheet metal housing, electrolytic galvanized high surface quality, powder-coated and abrasion-resistant casing 7 Gallon Insulated Plastic glycol/water reservoir Easy to fill from outside Evaporator coil made of stainless steel High-quality Grundfos recirculation pump Built in pressure switch shuts down recirculation pump when not needed Digital Thermostat Lifting/Crane Hooks for transport All panels remove for easy access All units pass multiple tests prior to shipment German Engineering Controlled by compact PC boards with a temperature accuracy up to 0.1 degree Celsius. 33"L x 25"W x 31.5"T Unit has 1" Male BSP w/ 3/4" Female BSP inlet / outlet 6 Month Electrical Warranty 1 Year Mechanical Warranty CE Certified Please Note: This unit REQUIRES 230 v Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. Available in larger sizes. For additional product options click here.

$21,999.99

-

MB® 20 bbl Brite Tank | T.C. Sanitary Ports | All Fittings Included | Carbonation Stone | Passivated Ready to Use | American Engineered | Ships from USA

Due to high demand, this item is currently out of stock. Be the first to receive your items by placing a pre-order today. We will automatically ship this to you when we receive more inventory. Designed by MB's in-house engineers with a focus on cleanability, ease of use, and durability Made from 304 stainless steel throughout with passivated 2B polished finished on the interior Sanitary tri-clamp connections from top to bottom with centered bottom drain, sight glass, and dedicated CIP pipe system—all fittings included! 15% extra headspace with a working volume of 20 bbl and max volume of 23 bbl Double walled with 80 mm thick polyurethane insulation and 1.5 mm thick dual cooling zone glycol jacket Ships domestically from within the contiguous United States MB offers a full range of professional level conical fermenters and brite tanks. Our stainless steel tanks represent an amazing overall value, boasting exquisite construction and a very impressive feature set. MB jacketed brite tanks are made from 304 stainless steel and built to high quality standards. All of our brite tanks are pressured tested at the factory, feature 100% sanitary welds, and are backed by our one year warranty. Every brite tank features an average 15% headspace not stated in the volume, so for example, a 10 bbl brite really has 11.5 bbl of volume. Great Quality from MB MB is a brand that we dedicate to crafting and sourcing the equipment pro brewers need to make an exceptional product efficiently and consistently. Our brite tanks between 1 and 60 bbl are designed by our in-house team of engineers with decades of professional brewing experience. Focusing on cleanability, ease of use, and durability, we’ve made sure our tanks have the features that modern brewers expect when purchasing a new tank. While some discount dealers chase down bargain priced tanks from a string of manufacturers, we have maintained a long running relationship with a single manufacturer that ensures the quality of our products never wavers. Great Value from MoreBeer! Pro If you used MoreBeer! as a homebrewer, you may not know that MoreBeer! & MoreBeer! Pro combined is one of the largest brewing supply companies in the world with over 250,000 customers. We’ve seen countless homebrewers turn pro, and there’s nothing that makes us happier than being a part of that transition. As a privately owned brewing supply company that's been in business for over 25 years, we’ve established relationships with suppliers and manufacturers around the world and at every level of the industry. We get a great price and we pass that on to you. Features Include: 15 PSI (1 bar) working pressure Side manway door for cleaning 1.5" Tri-clamp carbonation stone 1.5" Tri-clamp pressure gauge 1.5" Tri-clamp dial face bi-metal, easy-read analog thermometer 1.5" Tri-clamp Perlick-style sample valve 2" Tri-clamp pressure/vacuum relief 2" Center bottom tri-clamp drain 4" Hopping Port Ladder hooks Sight-glass for reading volumes Dedicated pipe system with 4" Tri-clamp center top opening and 1.5" tri-clamp rotating CIP spray ball for easy cleaning 3/4" NPT glycol ports PT100 Thermocouple interface Shadowless Manway Construction: 304 stainless steel construction Double walled with 80 mm thick polyurethane insulation External Shell: 2 mm thick with brushed finish Internal tank: 3 mm thick with smooth ground welds, 2B finish and passivated Glycol Jacket: dual cooling zone, 1.5mm thick Specifications: Tank Height: 100" Tank Diameter: 62" Empty Weight: 1,102 lbs Working Volume: 20 bbl Total Volume: 23 bbl Jacket Surface Area: 8,291 in² (5.349 m²) Please Contact our Customer Service department at 1-800-600-0033 to assess shipment costs and place an order.

$11,799.99