Kreyer Glycol Chillers

-

Kreyer Fan Unit | MR 75 | 1/3 Ton Cooling Capacity | Single Fan | For Rooms Up To 1,750 ft³ | 220V

Use your existing glycol system to cool your cellar Eliminates the need to purchase an entirely separate refrigeration system MR series fan units offer quieter operation compared to the SD-S units Sized for well-insulated rooms up to 1,750 ft³ Made in Germany by Kreyer Cool your cellar using your existing glycol system. Save energy and money! These units work under the same principles as standard refrigeration but use cooled glycol that you already have instead of cooled refrigerant gas, eliminating the need to have a separate refrigeration system. It is a fantastic use of your glycol system for a majority of the year when typically glycol systems are on but are being sporadically called upon. Glycol systems do need to be sized to accommodate both these fan units and peak duty during the crush to be able to accommodate all tasks at once. Glycol from your main glycol chiller is recirculated through these fan units. Aluminum fins act as heat exchangers drawing heat out of your room as the fins are cooled by the glycol. If you have a Kreyer chiller/heater you can even heat a space in cold weather environments. The heat exchangers inside the units are made from corrugated aluminum fins and internally grooved copper tubes. The white ABS casing looks great. Because of its rounded corners it has no water retaining areas favorable to germ development. Units are outfitted with stainless steel screws and show no sharp, cutting edges. The MR series is quieter than the SD series but not as robust in construction. Fan Unit Temp Control Upgrades: 1/2 in. Solenoid Valve - Allows or blocks flow of glycol through the fan unit. Needs to be connected to a Controller to function. A filter is recommended to protect the solenoid. 1/2 in. Solenoid Filter - protects the solenoid valve from any particulate or sediment. Glycol Fan Control Unit - Set a specific temperature on this controller and it will open and close the solenoid valve. Solenoid Connection Cable - This 2 meter long cable is required to connect the Solenoid Valve & Control unit. Specifications of MR75: Will cool well insulated spaces up to 1750 cubic feet while drawing 1/3 Ton of cooling power Single Fan Unit (pictured is 3 fan unit) 220V connection required to run fan You will need to connect to your existing glycol system Inlet and Outlet: 3/8" OD bare copper pipe

$744.99

-

Solenoid Connection Cable For Kreyer Fan Unit - 2 meter 230 volt

This cable connects a 230 v solenoid valve to its controller. Use with a kreyer fan unit, solenoid valve, and control unit to choose a specific temperature set point for your room.

$30.99

-

Kreyer Fan Temperature Controller | 1 Unit

This temperature control unit controls room/cooler/cave/cellar temperature when used in conjunction with a Kreyer fan unit. Kreyer fan units are plumbed to a Kreyer Glycol cooling unit. This unit turns on and off an optional solenoid placed at the inlet of the fan unit, which allows chilled glycol to enter the coils on the fan unit, while also turning on the fan(s) that blow cold air out into the room. Requires a fan unit, solenoid valve, & connection cable to function. Fan unit must be plumbed to a glycol machine. For a fan unit temperature controller to be used below freezing temperatures, see our GLY950.

$384.99

-

Kreyer Chilly 45 | Glycol Chiller | 1.2 Ton | 15,000 BTU Cooling Capacity | 220V Single Phase

Compact chiller with commercial level cooling power Maintain fermentation temperatures, cold-stabilize insulated tanks, or maintain storage temperatures Position inside the winery or outside in a covered position Fill from the exterior without the need to remove covers or panels Program and monitor temperatures via the digital controller Made in Germany by Kreyer This Chilly45 unit allows you to easily cool your ferment temperatures, cold-stabilize smaller insulated tanks, or maintain a wine tank storage temperature. This unit can be used inside the winery or placed in a covered position on the outside of the winery. Manufactured by Kreyer, the World's leading producers of wine-cooling equipment. Ready to go - fill with water or a water/glycol solution and plug in. They are equipped with an efficient scroll-type compressor. Note: This unit runs off 220V single phase power. It will not run off 208V. Uses Cooling of must for cold soaks, slow starting ferments Stabilization of tataric crystals Controlling fermenting temperatures Maintaining storage temperatures in tanks/barrels (ask about our barrel snake!) Features Sheet metal housing, electrolitic galvanized high surface quality, powder-coated and abrasion-resistant encasing cover that is easily detachable 220v single phase 60Hz 14 amp supply voltage 1.28 tons (15,000 btu) of cooling power 30L/8G Insulated Plastic tank to hold water or glycol Easy to fill from outside Centrifugal recirculation pump made by Speck. Digital Thermostat Integrated pump pressure switch allows unit to work with digital automatic temperature controlers on multiple tanks. NEW Micro Channel evaporator is quieter, more efficient and uses 30% less cooling gas. High Tech, Scroll-type, efficient, low noise compressor Environmentally friendly R404A refrigerant is optimized to work in low temperature ranges Non-Ferrous water circuit - No Rusting! Outlet is 3/4" MPT, which accomodates hose fittings with gaskets, and includes a 1/2" barb fitting 29.75" Length 23.6" Width 19.68" Height All units pass multiple tests prior to shipment 6 Month Electrical Warranty 1 Year Mechanical Warranty CE Certified Need a small glycol system designed for your needs? Contact Morebeer! Pro at info@morebeerpro.com or MoreWine! Pro at info@morewinepro.com

$8,599.99

-

Kreyer Fan Unit | MR 210 | 1 Ton Cooling Capacity | Triple Fan | For Rooms Up To 8,750 ft³ | 220V

Use your existing glycol system to cool your cellar Eliminates the need to purchase an entirely separate refrigeration system MR series fan units offer quieter operation compared to the SD-S units Sized for well-insulated rooms up to 8,750 ft³ Made in Germany by Kreyer Cool your cellar using your existing glycol system. Save energy and money! These units work under the same principles as standard refrigeration but use cooled glycol instead of cooled refrigerant gas, eliminating the need to have a separate refrigeration system. It is a fantastic use of your glycol system for a majority of the year when typically glycol systems are on but are being sporadically called upon. Glycol systems do need to be sized to accommodate both these fan units and peak duty during the crush to be able to accommodate all tasks at once. Glycol from your main glycol chiller is recirculated through these fan units. Aluminum fins act as heat exchangers drawing heat out of your room as the fins are cooled by the glycol. If you have a Kreyer chiller/heater you can even heat a space in cold weather environments. The heat exchangers inside the units are made from corrugated aluminum fins and internally grooved copper tubes. The white ABS casing looks great. Because of its rounded corners it has no water retaining areas favorable to germ development. Units are outfitted with stainless steel screws and show no sharp, cutting edges. Fan Unit Temp Control Upgrades: 1/2 in. Solenoid Valve - Allows or blocks flow of glycol through the fan unit. Needs to be connected to a Controller to function. A filter is recommended to protect the solenoid. 1/2 in. Solenoid Filter - protects the solenoid valve from any particulate or sediment. Glycol Fan Control Unit - Set a specific temperature on this controller and it will open and close the solenoid valve. Solenoid Connection Cable - This 2 meter long cable is required to connect the Solenoid Valve & Control unit. Specifications of MR210: Will cool well insulated spaces up to 8750 cubic feet while drawing 1 Ton of cooling power Triple Fan Unit 220V connection required to run fan You will need to connect to your existing glycol system Inlet and Outlet: 3/4" Male BSP

$1,539.99

-

Kreyer Fan Solenoid Valve | 230V | 1/2" FPT

Use this Solenoid valve to control glycol flow into a fan unit. These Solenoids should be combined with a Fan Temperature Controller and Connection Cable to set a specific temperature for your fan unit to achieve in your room. This is a 1/2 in. FPT threaded piece for MR210 Fan Units. It can also be used with MR75 & 135 units with a 3/8" barb adapter. We recommend purchasing a Solenoid Filter with this valve. The filter will ensure that no small particulates can get caught in the valve assembly, potentially damaging the unit. 230 v AC Solenoid with 1/2" FPT We also sell complete control kits for Kreyer fan units: MR75 & MR135 Control Kit MR210 Control Kit SD35L & SD73L Control Kit

$193.99

-

Filter for 1/2 in. Solenoid Valve

This small filter should be used inline before a 1/2 in. solenoid valve to protect it from damage from particulates.

$38.49

-

Kreyer Fan Unit | SD-S 35 | 1.6 Ton Cooling Capacity | Single Fan | For Rooms Up To 17,500 ft³ | 230V

Use your existing glycol system to cool your cellar Eliminates the need to purchase an entirely separate refrigeration system SD-S series fan units were designed specifically for high-moisture environments like wine cellars Sized for well-insulated rooms up to 17,500 ft³ Made in Germany by Kreyer Cool your cellar using your existing glycol system. Save energy and money! These units work under the same principles as standard refrigeration but use cooled glycol that you already have instead of cooled refrigerant gas, eliminating the need to have a separate refrigeration system. It is a fantastic use of your glycol system for a majority of the year when typically glycol systems are on but are being sporadically called upon. Glycol systems do need to be sized to accommodate both these fan units and peak duty during the crush to be able to accommodate all tasks at once. Glycol from your main glycol chiller is recirculated through these fan units. Aluminum fins act as heat exchangers drawing heat out of your room as the fins are cooled by the glycol. If you have a Kreyer chiller/heater you can even heat a space in cold weather environments. The heat exchangers inside the units are made from corrugated aluminum fins and internally grooved copper tubes. The white ABS casing looks great. Because of its rounded corners it has no water retaining areas favorable to germ development. Both series are fitted with stainless steel screws and show no sharp, cutting edges. The SD-S series has been designed especially for problematic environments such as wine-cellars with high moisture. The high-performance fans on the SD-S unit are lubricated for life. The SD-S 35 is sized to: Cool a room up to 17,500 when the ceiling and walls are well insulated. Cooling a room this size from 90F to 60F will use approximately 1.05 tons of cooling power from your chilling system. If the room is half insulated you will need approximately 50% more power or 1.6 tons of cooling power. Once you've achieved the desired temperature it takes considerably less power to maintain it. Fan Unit Temp Control Upgrades: 3/4 in. Solenoid Valve - Allows or blocks flow of glycol through the fan unit. Needs to be connected to a Controller to function. A filter is recommended to protect the solenoid. 3/4 in. Solenoid Filter - protects the solenoid valve from any particulate or sediment. Glycol Fan Control Unit - Set a specific temperature on this controller and it will open and close the solenoid valve. Solenoid Connection Cable - This 2 meter long cable is required to connect the Solenoid Valve & Control unit. Inlet and Outlet: 3/4" Male BSP Please Note: This unit only has one fan. The weight shown below is for shipping purposes, as this item ships at an oversize rate with UPS Ground. Actual weight of the fan is about 35lb. Actual Dimensions are 710x410x460mm

$1,649.99

-

Kreyer Fan Solenoid Valve | 230V | 3/4" FPT

Use this Solenoid valve to control glycol flow into a fan unit. These Solenoids should be combined with a Fan Temperature Controller and Connection Cable to set a specific temperature for your fan unit to achieve in your room. This is a 3/4 in. FPT threaded piece for SD35L & SD73L Fan Units. It can also be used with other 1" SD fans if an adapter is used. We recommend purchasing a Solenoid Filter with this valve. The filter will ensure that no small particulates can get caught in the valve assembly, potentially damaging the unit. 230 v AC Solenoid with 3/4" FPT We also sell complete control kits for Kreyer fan units: MR75 & MR135 Control Kit MR210 Control Kit SD35L & SD73L Control Kit

$241.99

-

Kreyer Fan Unit | SD-S 73 | 2.5 Ton Cooling Capacity | Double Fan | For Rooms Up To 28,000 ft³ | 230V

Use your existing glycol system to cool your cellar Eliminates the need to purchase an entirely separate refrigeration system SD-S series fan units were designed specifically high-moisture environments like wine cellars Sized for well-insulated rooms up to 28,000 ft³ Made in Germany by Kreyer Good for cooling cellars up to 28,000 cubic feet Cool your cellar using your existing glycol system. Save energy and money! These units work under the same principles as standard refrigeration but use cooled glycol that you already have instead of cooled refrigerant gas, eliminating the need to have a separate refrigeration system. It is a fantastic use of your glycol system for a majority of the year when typically glycol systems are on but are being sporadically called upon. Glycol systems do need to be sized to accommodate both these fan units and peak duty during the crush to be able to accommodate all tasks at once. Glycol from your main glycol chiller is recirculated through these fan units. Aluminum fins act as heat exchangers drawing heat out of your room as the fins are cooled by the glycol. If you have a Kreyer chiller/heater you can even heat a space in cold weather environments. The heat exchangers inside the units are made from corrugated aluminum fins and internally grooved copper tubes. The white ABS casing looks great. Because of its rounded corners it has no water retaining areas favorable to germ development. Both series are fitted with stainless steel screws and show no sharp, cutting edges. Built in defrosters help ensure the system is working at optimum efficiency The SD-S series has been designed especially for problematic environments such as wine-cellars with high moisture. The high-performance fans on the SD-S unit are lubricated for life. Fan Unit Temp Control Upgrades: 3/4 in. Solenoid Valve - Allows or blocks flow of glycol through the fan unit. Needs to be connected to a Controller to function. A filter is recommended to protect the solenoid. 3/4 in. Solenoid Filter - protects the solenoid valve from any particulate or sediment. Glycol Fan Control Unit - Set a specific temperature on this controller and it will open and close the solenoid valve. Solenoid Connection Cable - This 2 meter long cable is required to connect the Solenoid Valve & Control unit. Inlet and Outlet: 3/4" Male BSP The SD-S 73 is sized to: Cool a room up to 28,000 cubic feet when the ceiling and walls are well insulated. Will use approximately 2.5 tons of cooling power from your chilling system. If the room is half insulated you will need to move up to SD-S 110. Please be sure to consult with our Wine team for proper sizing of a fan unit.

$2,749.99

-

Kreyer Fan Unit | MR 135 | 2/3 Ton Cooling Capacity | Double Fan | For Rooms Up To 3,500 ft³ | 220V

Use your existing glycol system to cool your cellar Eliminates the need to purchase an entirely separate refrigeration system MR series fan units offer quieter operation compared to the SD-S units Sized for well-insulated rooms up to 3,500 ft³ Made in Germany by Kreyer Cool your cellar using your existing glycol system. Save energy and money! These units work under the same principles as standard refrigeration but use cooled glycol instead of cooled refrigerant gas, eliminating the need to have a separate refrigeration system. It is a fantastic use of your glycol system for a majority of the year when typically glycol systems are on but are being sporadically called upon. Glycol systems do need to be sized to accommodate both these fan units and peak duty during the crush to be able to accommodate all tasks at once. Glycol from your main glycol chiller is recirculated through these fan units. Aluminum fins act as heat exchangers drawing heat out of your room as the fins are cooled by the glycol. If you have a Kreyer chiller/heater you can even heat a space in cold weather environments. The heat exchangers inside the units are made from corrugated aluminum fins and internally grooved copper tubes. The white ABS casing looks great. Because of its rounded corners it has no water retaining areas favorable to germ development. Units are outfitted with stainless steel screws and show no sharp, cutting edges. Fan Unit Temp Control Upgrades: 1/2 in. Solenoid Valve - Allows or blocks flow of glycol through the fan unit. Needs to be connected to a Controller to function. A filter is recommended to protect the solenoid. 1/2 in. Solenoid Filter - protects the solenoid valve from any particulate or sediment. Glycol Fan Control Unit - Set a specific temperature on this controller and it will open and close the solenoid valve. Solenoid Connection Cable - This 2 meter long cable is required to connect the Solenoid Valve & Control unit. Specifications of MR135: Will cool well insulated spaces up to 3500 cubic feet while drawing 2/3 Ton of cooling power Double Fan Unit (pictured is 3 fan unit) 220V connection required to run fan You will need to connect to your existing glycol system Inlet and Outlet 3/4" Male BSP

$1,159.99

-

Filter for 3/4 in. Fan Solenoid Valve

This small filter should be used inline before a 3/4 in. solenoid valve to protect it from damage from particulates.

$38.49

-

Kreyer Fan Unit | SD-S 148 | 5.5 Ton Cooling Capacity | Quad Fan | For Rooms Up To 85,000 ft³ | 230V

Use your existing glycol system to cool your cellar Eliminates the need to purchase an entirely separate refrigeration system SD-S series fan units were designed specifically for high-moisture environments like wine cellars Sized for well-insulated rooms up to 85,000 ft³ Made in Germany by Kreyer Cool your cellar using your existing glycol system. Save energy and money! These units work under the same principles as standard refrigeration but use cooled glycol that you already have instead of cooled refrigerant gas, eliminating the need to have a separate refrigeration system. It is a fantastic use of your glycol system for a majority of the year when typically glycol systems are on but are being sporadically called upon. Glycol systems do need to be sized to accommodate both these fan units and peak duty during the crush to be able to accommodate all tasks at once. Glycol from your main glycol chiller is recirculated through these fan units. Aluminum fins act as heat exchangers drawing heat out of your room as the fins are cooled by the glycol. If you have a Kreyer chiller/heater you can even heat a space in cold weather environments. The heat exchangers inside the units are made from corrugated aluminum fins and internally grooved copper tubes. The white ABS casing looks great. Because of its rounded corners it has no water retaining areas favorable to germ development. Both series are fitted with stainless steel screws and show no sharp, cutting edges. Built in defrosters help ensure the system is working at optimum efficiency The SD-S series has been designed especially for problematic environments such as wine-cellars with high moisture. The high-performance fans on the SD-S unit are lubricated for life. Fan Unit Temp Control Upgrades: 1 in. Solenoid Valve - Allows or blocks flow of glycol through the fan unit. Needs to be connected to a Controller to function. A filter is recommended to protect the solenoid. 1 in. Solenoid Filter - protects the solenoid valve from any particulate or sediment. Glycol Fan Control Unit - Set a specific temperature on this controller and it will open and close the solenoid valve. Solenoid Connection Cable - This 2 meter long cable is required to connect the Solenoid Valve & Control unit. Inlet and Outlet: 1" Male BSP The SD-S 148 is sized to: Cool a room up to 85,000 cubic feet when the ceiling and walls are well insulated. Will use approximately 5.5 tons of cooling power from your chilling system. Please be sure to consult with our Wine team for proper sizing of a fan unit. This unit features 4 fans. Product Statistics Weight: 150lbs Dimensions: 82"L x 12"W x 18"H

$4,069.99

-

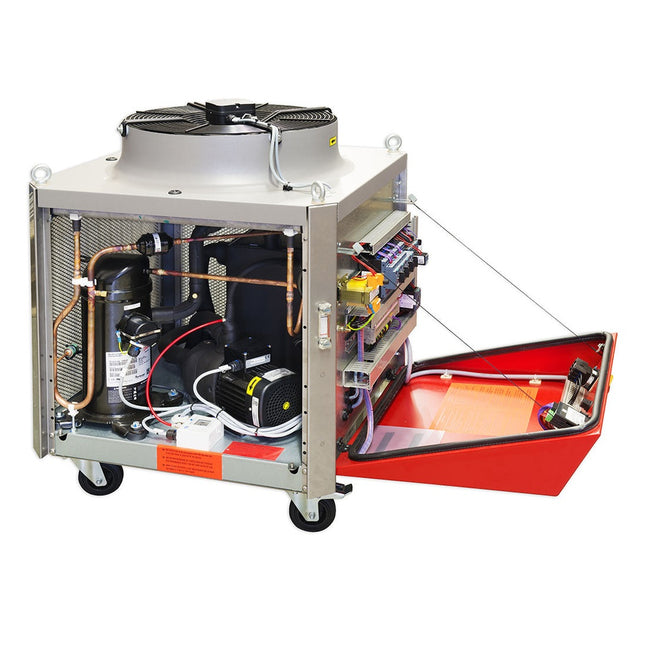

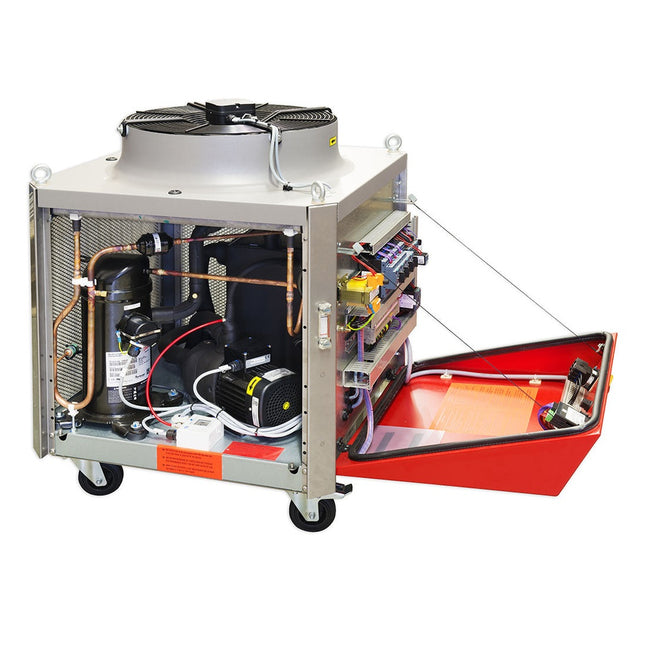

Kreyer Chilly Max 50 | Glycol Chiller/Heater | 1.8 Ton | 21,840 BTU Cooling Capacity | 230V 3 Phase

Cooling & heating in one premium quality unit Control fermentation temperatures, cold-stabilize insulated tanks, or heat tanks during cold weather Fill from the exterior without the need to remove covers or panels Program and monitor temperatures via the digital controller Non-Return Kit installed as standard to prevent backflow when positioned below your tank jacket, heat exchanger, or piping system Four locking casters offer ease-of-mobility when moving the unit around the winery 1.8 Ton / 21,840 Btu cooling capacity 230V, 3 Phase power Made in Germany by Kreyer Cooling and Heating in one unit! Every Winemaker can appreciate the benefits of precise temperature control during all stages of production. This mobile unit allows you to easily control your ferment temperatures, heat your tanks during winter to expedite Malo-Lactic fermentation, or cold-stabilize your white wines. This unit can be used as portable unit in a larger winery or as a fixed system supplying a glycol loop in a smaller winery. Unit is used for heating or cooling but cannot supply both at the same time. Manufactured by Kreyer, the World's leading producers of wine-cooling equipment. Note: This unit runs off 230V 3 phase power. It will not run off 208V. Uses: Cooling of must for cold soaks, slow starting ferments Heating up must after a cold soak period Cold Stabilization of tartaric crystals Controlling fermenting temperatures through cooling or heating Maintaining storage temperatures in tanks/barrels Check out these features: Cools or Heats 1.8 Tons (21,840btu) of cooling power .85 Tons of heating power Can cool glycol/water bath down to -10C/14F or up to 42C/107F 230V 60Hz 3 phase supply voltage drawing 13.1 amps Rolls on four locking casters Sheet metal housing, electrolytic galvanized high surface quality, powder-coated and abrasion-resistant casing 7 Gallon Insulated Plastic glycol/water reservoir Easy to fill from outside Evaporator coil made of stainless steel High-quality Grundfos recirculation pump Built in pressure switch shuts down recirculation pump when not needed Digital Thermostat Lifting/Crane Hooks for transport All panels remove for easy access All units pass multiple tests prior to shipment German Engineering Controlled by compact PC boards with a temperature accuracy up to 0.1 degree Celsius. 33"L x 25"W x 31.5"T Unit has 1" Male BSP w/ 3/4" Female BSP inlet / outlet 6 Month Electrical Warranty 1 Year Mechanical Warranty CE Certified Please Note: This unit REQUIRES 230 v Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. Available in larger sizes. For additional product options click here.

$12,099.99

-

Quantor Yeast Booster Pro | Automatic Dry Yeast Hydration | 110L | 29G | 110V

Healthy, strong, properly rehydrated yeast cells that are prepared for a perfect fermentation Automated process saves labor Repeatability: process can be repeated by the machine without variables from human preparation Increased viability and cell count reduces the amount of yeast needed. The German made Yeast Booster Pro from Quantor offers a labor saving, precise, repeatable method for rehydrating dry yeast. Designed to rehydrate up to 2,000 grams of yeast at a time (available Yeast Booster Max handles up to 10,000 grams) with built-in temperature control and automated pumping in of water and juice. The result is consistently healthy yeast, producing optimum flavors, with greatly reduced chances of stuck fermentation. The Yeast-Booster is run by a processor. All the required parameters can be set in the menu: start temperature, target temperature, time, etc. From the menu change the language and adjust the display lighting contrast. In the start phase the water will be heated to 101.3°F/38.5°C. Upon reaching the target temperature the yeast is added to the mixture. During the first phase of the propagation, the yeast will be gently circulated through a membrane pump, which will break up lumps and add oxygen to the mixture. Fresh must from the target tank will be added to the mixture every 15 minutes to acclimate the yeast. At the end of the up-scaling process, the propagated yeast mixture will be pumped into the target tank. The Yeast-Booster can then start the rinsing and cleaning cycle. The cycle lasts 2-3 hours, allowing time for cells to become active and begin replication. The Yeast Booster is equipped with robust motorized valves, a strong pump for faster emptying, and a perforated stainless screen at the bottom of the tank breaking-up remaining clumps of dry-yeast to reach a fine, homogenous mixture. The unit is jacketed for connection to water (or glycol) for cooling and also features a built-in electric heater for precise temperature control during rehydration. Tank, screen, control panel, and frame are made from stainless steel. 110V, Single Phase, 60Hz

$11,399.99 - $13,499.99

-

Defrost Kit for Kreyer Fan Unit | S-DS 35

When using a Kreyer Fan unit for below freezing temperatures, you must also use their matching defrost kit. Kreyer Defrost Kits consist of an electric heating element or spiral and are fitted directly to their respective fan unit cooling fins. The Defrost Kit melts any iced condensate that can accumulate on the fins when the fan is used with Glycol-Water set below the freezing point. The Defrost Kit will periodically melt any iced condensate allowing you to use your fan unit at low temperatures. Requires 230V Single Phase 50/60Hz Best if used with Kreyer Masterlog Controller (SDML) Please note: example image shown. The defrost kit may not exactly match this image.

$384.99

-

Defrost Kit for Kreyer Fan Unit | MR 75

Defrost Kits are electric heating elements made of a set of thin metallic heating rods that are fitted into the suitable slots, under the coil of the thermo-fan. This layout simplifies the installation and guarantees homogenous dispersion of heat over the entire coil for even defrosting. The Defrost Kit melts the iced condensate, which accumulates on the airways when the fan is used for room cooling with Glycol-water set below the freezing point. Periodical defrosting enables the use of the thermo-fan for setting up cold-rooms, which are kept at low temperatures. The melted condense water drips to the fan's collection tray for drainage. When using a Defrost Kit, it is required to use the FermFlex-Defrost controller, which controls both the fan-valve for cooling and the heating element for defrosting.

$494.99

-

Defrost Kit for Kreyer Fan Unit | MR 210

Defrost Kits are electric heating elements made of a set of thin metallic heating rods that are fitted into the suitable slots, under the coil of the thermo-fan. This layout simplifies the installation and guarantees homogenous dispersion of heat over the entire coil for even defrosting. The Defrost Kit melts the iced condensate, which accumulates on the airways when the fan is used for room cooling with Glycol-water set below the freezing point. Periodical defrosting enables the use of the thermo-fan for setting up cold-rooms, which are kept at low temperatures. The melted condense water drips to the fan's collection tray for drainage. When using a Defrost Kit, it is required to use the FermFlex-Defrost controller, which controls both the fan-valve for cooling and the heating element for defrosting.

$624.99

-

Defrost Kit for Kreyer Fan Unit | MR 135

Defrost Kits are electric heating elements made of a set of thin metallic heating rods that are fitted into the suitable slots, under the coil of the thermo-fan. This layout simplifies the installation and guarantees homogenous dispersion of heat over the entire coil for even defrosting. The Defrost Kit melts the iced condensate, which accumulates on the airways when the fan is used for room cooling with Glycol-water set below the freezing point. Periodical defrosting enables the use of the thermo-fan for setting up cold-rooms, which are kept at low temperatures. The melted condense water drips to the fan's collection tray for drainage. When using a Defrost Kit, it is required to use the FermFlex-Defrost controller, which controls both the fan-valve for cooling and the heating element for defrosting.

$549.99

-

FermFlex Temperature and Defrost Controller for Kreyer Fan Units

This temperature and defrost controller is required when using a Kreyer defrost kit. The temperature control unit controls room/cooler/cave/cellar temperature when used in conjunction with a Kreyer fan unit. Kreyer fan units are plumbed to a Kreyer Glycol cooling unit. This unit turns on and off an optional solenoid placed at the inlet of the fan unit, which allows chilled glycol to enter the coils on the fan unit, while also turning on the fan(s) that blow cold air out into the room. When using a Kreyer Fan unit for below freezing temperatures, you must also use their matching defrost kit. Kreyer Defrost Kits consist of an electric heating element or spiral and are fitted directly to their respective fan unit cooling fins. The Defrost Kit melts any iced condensate that can accumulate on the fins when the fan is used with Glycol-Water set below the freezing point. The Defrost Kit will periodically melt any iced condensate allowing you to use your fan unit at low temperatures. For use with MR, SD-S, SD Plus, and TA Kreyer Fan Units. For a fan unit temperature controller to be used above freezing temperatures, see our GLY980.

$1,759.99

-

Kreyer Chilly 45 | Replacement Ball Valve

Replacement inlet / outlet ball valve for the Kreyer Chilly 45 glycol chiller.

$19.99

-

Kreyer SR 13 | Inline Cooling and Heating Unit | Wine and Must | Tube in Tube Heat Exchanger | 11.7 Ton

Use: The most versatile cooling and heating tool a winery can own Pump must or wine throught the machine | Heats or cools inline The only practical solution for cooling or heating crushed grapes 2" ID stainless steel tube-in-tube heat exchanger allows crushed grapes to pass through Use your choice of pumps to move product through SR chiller/heater Made in Germany | Used for over 40 years in French and German wineries Features: Plenty of Power | 11.7 Tons (140,400btu) of Cooling power Wide Temperature Range | 28F or up to 113F Moves Where You Need It | Rolls on four locking casters Control Temperatures with Ease | Digital Thermostat Top Class Components The most versatile cooling and heating tool a winery can own. Whether you want to cool crushed grapes to cold soak temperatures, heat a sluggish ferment, heat a tank for ML without having a dedicated hot water loop, or cold stabilize a tank quickly, the SR is an extremely useful machine. It often eliminates the need for a separate heating loop in your winery. It is loved for quickly doing cold stabilization on one tank at a time. It is more effective at cooling crushed grapes than trying to cool in a tank. Because it is a closed system it can be used with sparkling wine or cider without losing carbonation. Most wineries who use an SR for cooling/heating specific tanks or vats also have a dedicated main chiller connected to their permanent cooling loop. However the SR can also act as the back up chiller in case your main chiller goes down. You can use the SR to chill a tank, such as a large HDPE tank. Connect that tank to your glycol loop and if your main chiller goes down you already have a backup plan in place. Made in Germany, thousands of Kreyer SR chillers have been in use for over 40 years in France and Germany. The SR is not like a regular glycol chiller where a cooled bath is pumped into the tank jackets. The SR features a large, tubular heat-exchanger that is completely insulated. Your product is pumped through the inner tube while heat or cold travels the opposite direction through the outer tube. The top half of the SR houses the compressor for cooling while heating is performed in the Heat-Pump operation mode. The SR is uniquely designed unit for changing the temperature inline of crushed grapes, wine, sparkling wine, water, cider, fruit juice and distillates. By setting the temperature, you can rely on the SR to maintain tank temperature for as long as needed, in either heating or cooling mode. The case of the unit as well as all parts that come in contact with the treated medium are made of stainless steel. The ventilation grills are lacquered in black. Due to its four wheels, this SR unit is easy to maneuver. This allows the user to cool or to heat single tanks or other containers, as required. For example: starting a stopped fermentation by heating the tank content. Your choice of external pump is controlled by the SR’s control panel. The cooling units of the SR series are available in seven different sizes. This is 11.7 Ton model. Smaller and larger machines are available for quote. Applications: Direct cooling or heating of must at the beginning of fermentation Tartaric stabilization of wines Warming up wine from storage to bottling temperature Biological reduction of acids Regulation of fermentation temperature Cool storage of wine until bottling Suitable for sparkling wine and carbonated beverages (closed loop with no carbonation loss) Cooling of liquids with particles such as unfiltered juice Air cooling of the cellar in combination with additional equipment (thermo-fans and accessories) Check out these features: Cools or Heats 11.7 Tons (140,400btu) of cooling power Can maintain temps from 23F to 113F. 230V 60Hz 3 phase supply voltage drawing 40 amps Mobile unit with 4 casters, two locking Sheet metal housing, electrolytic galvanized high surface quality, powder-coated and abrasion-resistant casing Control an external cellar pump from the SR's control panel Evaporator coil made of stainless steel Automatic control of the wine pump according to set temperature Digital Thermostat Lifting/Crane Hooks for transport Panels remove for easy access All units pass multiple tests prior to shipment German Engineering Controller display shows temperature accuracy up to 0.1 degree Celsius. 41.3"L x 41.3"W x 84.6"T Empty Weight: 992 lbs Unit has 2" tri-clamp inlet / outlet 6 Month Electrical Warranty 1 Year Mechanical Warranty CE Certified Please Note: This unit REQUIRES 230 v Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord.

$39,599.99

-

Kreyer Centrifugal Humidifier | HumiFix 1 | 2,800 ft³/h Air Flow | 110V

Control the humidity of your cellar to prevent wine barrels from drying out Dry, non-humidified barrels will draw liquid to the outer surface where it evaporates, leading to significant product loss Can operate in environments as low as 34°F, making it ideal for cold rooms and storage halls Compact, stand-alone unit can be suspended from or mounted to a wall 2,800 cubic feet per hour air flow Made in Germany by Kreyer Humidity control in wine cellars plays a major role during the production, maturation and storage of wine and other beverages in wooden barrels. Wine barrels safe-guard the main asset of a winery – the wine itself. The wooden walls of dry, non-humidified barrels will draw liquid from inside it up through the small crevices to the outer surface where it evaporates. Over time, this leads to a significant amount of product loss. For example, a 225L wine barrel can lose 10-15% of the wine volume over one year. A professional humidification of the barrel room allows the barrel wood to absorb water-vapor, the crevices fill out and loss of wine is prevented. A well-kept barrel room is therefore cool, usually around 57-60°F and humidified at about 75% - 80% rH. As with every aspect of winemaking, attention and professional equipment are required. Low humidification may allow the wood to dehydrate and wine will evaporate through it, while overly high humidity can lead to mold and fungus. The centrifugal humidifier HumiFix is equipped with a spinning disk that vaporizes water into very fine droplets that can be easily absorbed by the surrounding air, humidifying and cooling a room at the same time. The unit can work either connected to your main water supply with inline cartridge filtration or more ideally to an RO unit. The HumiFix can work at low temperatures (down to 34°F), which is ideal for installation in cold rooms and storage halls. Features: Stand-alone unit Easy installation and handling Compact construction Wall or suspended mounting Specifications: Water Output: 1.0 L/h (0.26 Gal/h) Air Flow: 80 m³/h Power: 31 watts Power Connection: 110V/1Ph/60Hz Dimensions: 15.5" L x 12" W x 15.5" H Empty Weight: 10 lbs Please note: this unit comes with a bare cord so it can be hard wired to a controller. Otherwise we recommend attaching a 110V male plug and using it with the Inkbird Digital Humidity Controller.

$1,759.99

-

Ball Valve for Kreyer Fans - 1 in. BSP

Nickel plated 1" ball valve. Male BSP x Female BSP.

$38.99