At some point during the ageing process, whenever you like the way the wine tastes, it will be time to bottle. To bottle your wine, you will need wine corks, wine bottles, and a wine bottle corker. Getting the wine into the bottle can be as simple as: 1) creating a syphon using a racking cane, some tubing and a bottling wand, 2) using a gravity bottle filler (fed by a pump or gravity), or 3) using a vacuum pump to gently draw the wine into the bottles, as is the case with our Enolmatic wine bottle filler.

Once the wine is bottled, our wine bottle labeling machines and bottle dressing options will help you put the final touches on your masterpiece.

Complete information on bottling your wine can be found in our Red Winemaking and White Winemaking Manuals!

Bottling Wine

-

Marchisio Upright Foil Spinner | Replacement Lower Flange

Replacement lower support flange for the Marchisio Upright Foil Spinner.

$76.99

-

Thermoseal Hoods | White

White Thermoseal Hoods. Plastic heat shrink hoods are the choice of the wine industry which is moving from using lead capsules. Use a hot air dryer, air gun, or steam to shrink for an easy and effective way to seal your wine bottle. Bag of 30.

$5.99

-

ZEUS Special 75 Corker | Vacuum Device w/ Adapter for Farro Glass 0.75L to 1.5L Champagne Bottles

An optional vacuum device for the Zeus Large Format Bottle Corker. This model has an adpater designed to work with Farro brand Champagne Bottles from 750mL to 1.5L. The bottle interface was specifically machined for the Farro Champagne bottles so that the o-ring makes an airtight seal during the corking process. Creating a vacuum in the bottle prior to corking removes oxygen but also reduces pressure in the headspace which can potentially cause corking issues. This vacuum adapter requires the connection of an air compressor to create the vacuum. See here for the vacuum device with adapter for 3L still wine bottles and 5L still wine bottles.

$329.99

-

ZEUS Special 75 Corker | Vacuum Device w/ Adapter for Farro Glass 5L Still Wine Bottles

An optional vacuum device for the Zeus Large Format Bottle Corker. This model has an adpater designed to work with Farro brand 5L Glass Wine Bottles. The bottle interface was specifically machined for the Farro 3L bottle so that the o-ring makes an airtight seal during the corking process. Creating a vacuum in the bottle prior to corking removes oxygen but also reduces pressure in the headspace which can potentially cause corking issues. This vacuum adapter requires the connection of an air compressor to create the vacuum. See here for the vacuum device with adapter for 3L still wine bottles and Champagne bottles.

$329.99

-

Electric Bottle Corker | Vacuum | Gas Injection | Hopper | Auto Loading | Rolling Base | P35 | MEP

The Italian-made P35 electric corker from MEP will offer your winery extraordinarily quick and semi automatic operation for small to medium format wine bottles. Easily toggle between vacuum or gas injection with the turn of a knob. The perfect corker for either short term bottling or long term aging. Two handed operation for safety. Suitable for bottles up to 375 mm (14.75") in height and cork diameter ranging from 22 to 26 mm. This range covers all standard bottles and some larger format bottles, such as standard magnums. Features stainless steel jaws, stainless casing, rolling base, and automatic cork loading. MEP has been a trusted supplier of commercial equipment to the wine industry for decades. We are proud to be official distribution partners of MEP, having a direct relationship with ownership. This relationship allows us to service you better, be it questions or replacement parts. Specs: AISI 304 stainless steel frame Stainless steel jaws Electric operation (110V) Easily toggle between vacuum or gas injection Automatic loading of the corks Rolling base Diameter of corks: 22-26 mm Height of corks: up to 50 mm Height of bottles: up to 375 mm Corking time: ~1.8 seconds 110V, 60 Hz Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$9,899.99

-

Pneumatic Bottle Corker | Hopper | Rolling Base | P12 | MEP

The Italian-made P12 pneumatic corker from MEP will offer your winery fast and reliable operation for small to medium format wine bottles. Suitable for bottles up to 375 mm (14.75") in height and cork diameter ranging from 22 to 26 mm. Features stainless steel jaws, stainless casing, and cork hopper with mechanical stirrer. Comes with stainless trolley with rolling casters. Specs: AISI 304 stainless steel frame Stainless steel jaws Pneumatic operation Manual loading of the corks Hopper w/ mechanical stirrer Diameter of corks: 22-26 mm Height of corks: up to 50 mm Height of bottles: up to 375 mm Corking time: ~3 seconds

$5,499.99

-

MEP Pneumatic Bottle Corker | P12 Replacement Mixing Device Spring | Pos. 112

P12 Replacement Part. Spring for mixing device. Position 112.

$10.99

-

Tapered Cork #36

Top quality cork has been the traditional closure of choice for wine bottles for centuries. Give your wine that traditional finishing touch. Cork is natural, flexible, and compressible. Once it is securely in the bottle it has reliable anti-slip properties. This Size 36 Tapered Cork is made from ""XX"" quality natural cork. It is biodegradable and recyclable. A long time favorite for the long-term aging of wine. Top diameter: 2-5/8 in, Length: 1-1/2 in, bottom diameter: 2-11/32 in. Made in Portugal.

$3.79

-

Tapered Cork #42

Top quality cork has been the traditional closure of choice for wine bottles for centuries. Give your wine that traditional finishing touch. Cork is natural, flexible, and compressible. Once it is securely in the bottle it has reliable anti-slip properties. This Size 42 Tapered Cork is made from ""XX"" quality natural cork. It is biodegradable and recyclable. A long time favorite for the long-term aging of wine. Top diameter: 3 in, Length: 1-1/2 in, bottom diameter: 2-23/32 in. Made in Portugal.

$4.99

-

$3.99

-

Replacement Control Box | EnoItalia Wine Bottle Filler | WE670

Replacement Control Box for EnoItalia Wine Bottle Filler w/ electronic level sensor and integrated pump -- WE670.

$394.99

-

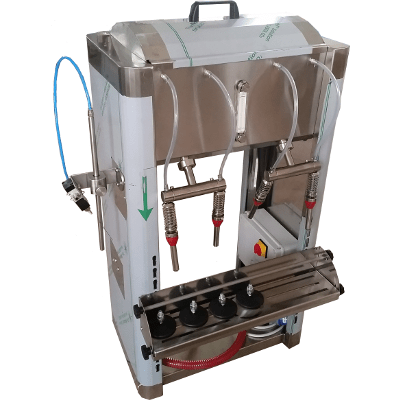

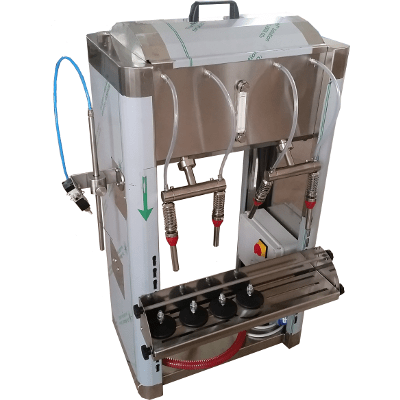

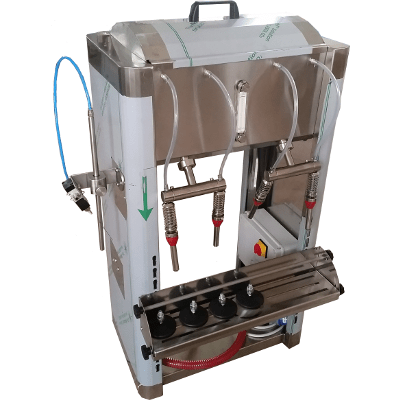

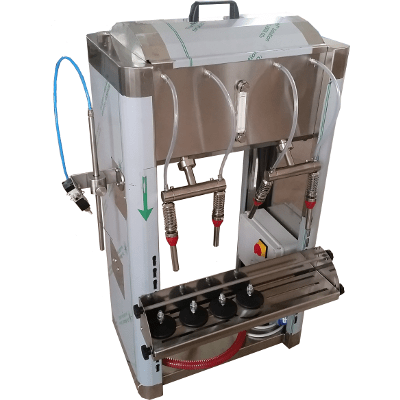

EnoItalia Deluxe Wine Bottle Filler | 4 Spout | Benchtop Bottle Filler | Electronic Level Sensor | Nitrogen Injector | Stainless Steel | 670L/h Fill Rate

Portable, benchtop gravity-style wine bottle filler Deluxe model with electronic level sensor and nitrogen injector valve Four filling heads made from stainless steel are removable for easy cleaning All parts that come into contact with wine are made from stainless steel Level gauge located at the front of the 45L reservoir Fill up to 65 cases of 750ml bottles per hour Made in Italy by EnoItalia The Enoitalia bottle filler is a complete, portable, gravity style bottle filler perfect for a small winery or avid home winemaker. Features four filling heads and stainless steel construction. Fill up to 65 cases of 750ml bottles per hour. The Deluxe model comes with an electronic level sensor that can be wired to a pump and a manual nitrogen injector valve mounted to the side. Compared to units from other Italian manufacturers, this unit has removable filling heads for easy cleaning. The air removal tubes are also larger, which speeds filling. The fill head is also easier to adjust for for bottle fill heights. The filler can be adapted for use with high viscosity liquids like olive oil with the use of a special filling head. Features: Adjustable heads are easily removed for cleaning All parts in contact with the wine are made from 304 type stainless steel Level gauge located at the front of the reservoir 15mm diameter filling head Fill height is easily adjustable Larger inner diameter fill head for faster air/gas removal from the bottle for a faster fill rate 670L per hour fill rate 45L reservoir 84 pounds 42" H x 23" W x 20" D

$2,639.99

-

EnoItalia Deluxe Wine Bottle Filler | 6 Spout | Benchtop Bottle Filler | Electronic Level Sensor | Nitrogen Injector | Stainless Steel | 980L/h Fill Rate

Portable, benchtop gravity-style wine bottle filler Deluxe model with electronic level sensor and nitrogen injector valve Six filling heads made from stainless steel are removable for easy cleaning All parts that come into contact with wine are made from stainless steel Level gauge located at the front of the 66L reservoir Fill up to 100 cases of 750ml bottles per hour Made in Italy by EnoItalia The Enoitalia bottle filler is a complete, portable, gravity style bottle filler perfect for a small winery or avid home winemaker. Features six filling heads and stainless steel construction. Fill up to 100 cases of 750ml bottles per hour. The Deluxe model comes with an electronic level sensor that can be wired to a pump and a manual nitrogen injector valve mounted to the side. Compared to units from other Italian manufacturers, this unit has removable filling heads for easy cleaning. The air removal tubes are also larger, which speeds filling. The fill head is also easier to adjust for for bottle fill heights. The filler can be adapted for use with high viscosity liquids like olive oil with the use of a special filling head. Features: Adjustable heads are easily removed for cleaning All parts in contact with the wine are made from 304 type stainless steel Level gauge located at the front of the reservoir 15mm diameter filling head Fill height is easily adjustable Larger inner diameter fill head for faster air/gas removal from the bottle for a faster fill rate 980L per hour fill rate 66L reservoir 110 pounds 42" H x 34" W x 20" D Please note: the example photo shows the 4-spout version of the bottle filler.

$3,079.99

-

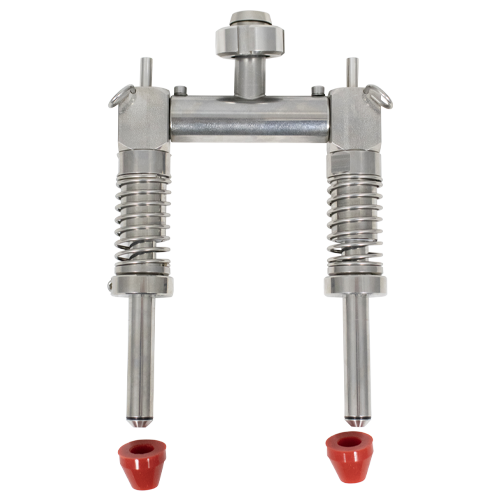

EnoItalia | Olive Oil Filling Head | 2 Spout | For Gravity Wine Bottle Fillers

Adapt your existing EnoItalia gravity fed wine bottle filler for use with high viscosity liquids Larger 17 mm diameter fill nozzles are designed for better flow with liquids like olive oil Compatible with EnoItalia Benchtop, Deluxe Benchtop, and Trolley Style wine bottle fillers The Olive Oil Filling Head can be swapped out for the standard filling head on EnoItalia gravity wine bottle fillers. It features a 17 mm Ø spout instead of the standard 15 mm Ø in order to handle more viscous liquids like olive oil. Compatible With: EnoItalia Benchtop Bottle Fillers WE253, WE257 EnoItalia Deluxe Benchtop Bottle Fillers WE254, WE258 EnoItalia Trolley Style Bottle Fillers WE643, WE670

$439.99

-

Enolmaster Wine Bottle Filler (Vacuum Filler) - 4 Spout - USED REFURBISHED

Used – Refurbished This unit is used. It has been restored to working order. It will have cosmetic defects and show signs of previous use. It is still covered by our No Hassle Return Policy and 1 Year Warranty Policy. A commercial version of the Enolmatic filler that features four filling heads and allows you to fill up to 600 bottles per hour. This is the best bottle filler for the large-scale home winemaker or a small commercial operation. Through the use of a vacuum, the Enolmaster filler automatically starts a siphon, sucks the air out of your wine bottles to preserve freshness, and automatically shuts off when each bottle is filled to the perfect height every time. Not only does the entire process take place in a nearly oxygen-free environment, preserving the freshness of your wine, the rate of fill is extremely fast allowing you to bottle up to 600 bottles per hour. The Enolmaster creates a vacuum that sucks the wine directly from your fermenter, storage tank, or barrel, which can be located up to 12 feet below the Enolmaster. No need to start a siphon or to have to pump or move your wine above your filling machine. The vacuum simultaneously sucks the air out of your bottle allowing you to fill in a nearly oxygen-free bottle. This quality-first process helps to ensure that the delicate flavors of your wine, the flavors you worked so hard to get, are not lost in an open-air bottling process. Additionally, there are no moving parts in contact with the wine ensuring the gentlest handling possible. Fill speed can be adjusted allowing you to bottle at your preferred pace. While the filler is in operation, wine is not allowed back into the storage tank or barrel due to a one-way valve located in the supply line. The small amount of excess wine runs into a collection reservoir. The fill height can be adjusted and can be used with any size or type of bottle. The Enolmaster is a commercial product designed for a small winery. It has a continuous duty cycle, meaning it can run non-stop and is constructed entirely from food-grade materials. The frame is made of stainless steel as are the filling heads. Simply run water through the system to clean out the lines. The reservoir for excess overfill can be rinsed out or ran through the dishwasher. To filter your wine and bottle fill at the same time, add the optional in-line Tandem Professional Filter Housing and Filter Cartridges. Base and frame made from 304 stainless steel Fill nozzels made from 316 stainless steel Fill up to 600 x 750ml bottles per hour Made in Italy by Tenco Dimensions: 650m x 460mm x 450m Weight: 25 kg (55 lbs) Power: 110V / 60hz / 120W Fill bottles from 180 - 350 mm (7" - 13.75") in height Fits bottles with inner neck diameters of 16 - 28 mm (5/8"- 1.1")

$3,299.99 $2,399.99

-

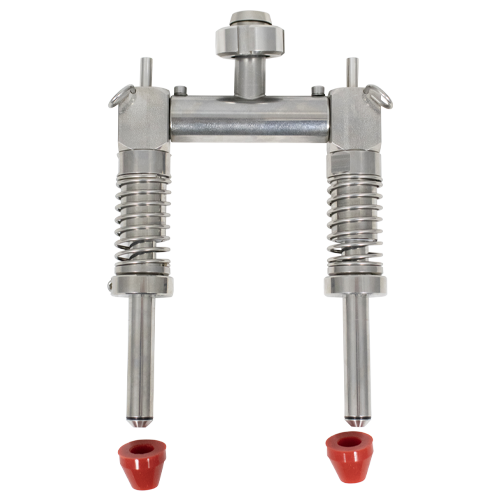

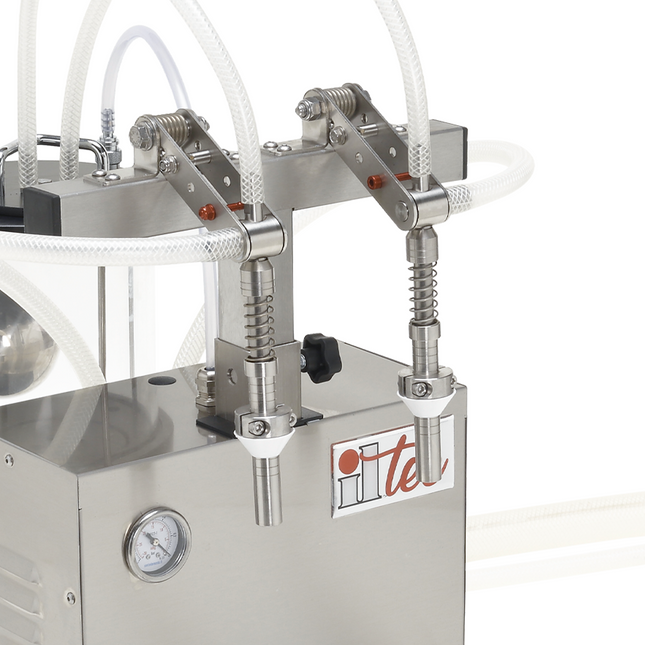

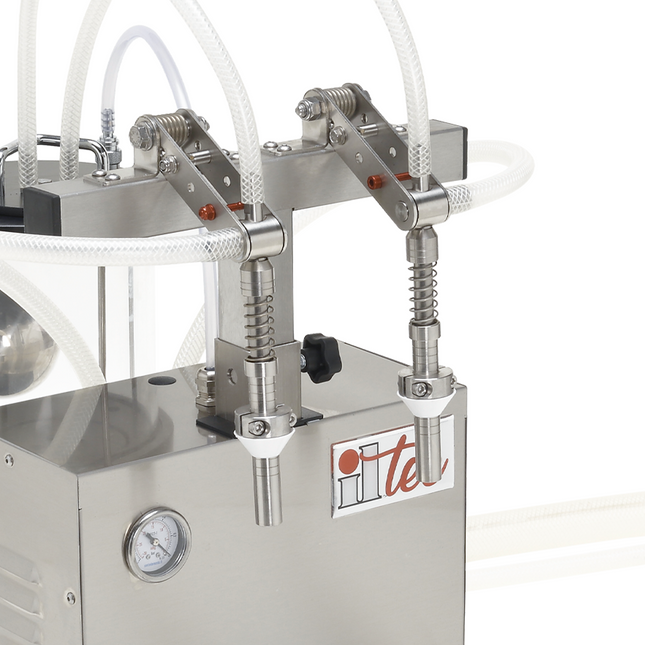

ILTEC Ultrafiller 2 | Vacuum Bottle Filler | 2 Spout | Pneumatic

Adjustable filling height with automatic stop Stainless steel base, frame, and filling nozzles Adjustable filling level and filling speed Vacuum gauge The Ultrafiller 2 is built entirely in stainless steel with PYREX tank, featuring two high efficiency and precision stainless steel filling nozzles. This professional bottling machine is perfect for wine, uncarbonated beer or cider, spirits, and oils. When you place the bottle under the Ultrafiller 2, the fluid is sucked into the vacuum created inside it, without any contact between the liquid and the pumps or mechanical components. Why Choose ILTEC While the Enolmatic has served as a great economical option, the ILTEC offers a significant step up in overall quality and durability. The key differences speak for themselves: Stainless Steel Construction: Unlike the Enolmatic's plastic components, the ILTEC boasts a robust stainless steel construction, ensuring long-lasting performance and easy sanitation. Borosilicate Vacuum Chamber: The ILTEC utilizes a borosilicate vacuum chamber, a superior alternative to the plastic chamber found in the Enolmatic. Borosilicate glass is known for its exceptional resistance to thermal shock and chemical corrosion, guaranteeing a cleaner and more efficient filling process. The ILTEC filler isn't just about superior materials; it's about delivering consistent, precise, and professional results. Whether you're bottling wine, spirits, oils, or other liquids, the ILTEC provides the performance you demand. Specs: Capacity: 400 x 750mL bottles per hour* Bottle Neck Diameter: 16-34mm Bottle Height: 7" to 13.75" (180-350mm) Tank Alcohol Tolerance: 80% ABV Max Temperature: 176°F (80°C) Dimensions: 13" x 21.6" 16.5" (330 x 550 x 420mm) Weight: 42.3 lbs Power: Compressed Air *Capacity may change depending on liquid and bottle size.

$1,869.99

-

ILTEC Ultrafiller 4 Pomodoro | Tomato Sauce | Vacuum Bottle Filler | 4 Spout | Pneumatic

Completely dedicated to thicker liquids, such as tomato sauce Adjustable filling height with automatic stop Stainless steel base, frame, and filling nozzles Adjustable filling level and filling speed Vacuum gauge This filler is the version of the Ultrafiller completely dedicated to denser liquids, such as tomato puree and other sauces. Various modifications applied to the standard machine allow bottles to be filled quickly and easily. Thanks to the larger rubber cone, it is possible to fill both bottles with crown caps and those with screw caps. This pneumatic version is the most powerful machine ever seen on the market—allowing for fast filling even with the thickest sauces. The Ultrafiller Pomodoro is built entirely in stainless steel with PYREX tank, featuring four high efficiency and precision stainless steel filling nozzles. When you place the bottle under the Ultrafiller Pomodoro, the fluid is sucked into the vacuum created inside it, without any contact between the liquid and the pumps or mechanical components. Why Choose ILTEC While the Enolmatic has served as a great economical option, the ILTEC offers a significant step up in overall quality and durability. The key differences speak for themselves: Stainless Steel Construction: Unlike the Enolmatic's plastic components, the ILTEC boasts a robust stainless steel construction, ensuring long-lasting performance and easy sanitation. Borosilicate Vacuum Chamber: The ILTEC utilizes a borosilicate vacuum chamber, a superior alternative to the plastic chamber found in the Enolmatic. Borosilicate glass is known for its exceptional resistance to thermal shock and chemical corrosion, guaranteeing a cleaner and more efficient filling process. The ILTEC filler isn't just about superior materials; it's about delivering consistent, precise, and professional results. Whether you're bottling wine, spirits, oils, or other liquids, the ILTEC provides the performance you demand. Specs: Capacity: 400 x 750mL bottles per hour* Bottle Neck Diameter: 16-34mm Bottle Height: 7" to 13.75" (180-350mm) Tank Alcohol Tolerance: 80% ABV Max Temperature: 176°F (80°C) Dimensions: 19.6" x 21.6" 16.5" (500 x 550 x 420mm) Weight: 55.1 lbs Power: Compressed Air *Capacity may change depending on liquid and bottle size.

$2,799.99

-

ILTEC Ultrafiller 4 | Mixed Spout | Vacuum Bottle Filler | 4 Spout | 110V

Adjustable filling height with automatic stop Stainless steel base, frame, and filling nozzles Adjustable filling level and filling speed Vacuum gauge Removable spouts for hand filling bottles away from the platform (left-hand and right-hand spouts only) The Mixed Ultrafiller 4 combines 2 standard spouts with 2 two small spouts for the best compromise for those who bottle small batches with a great variety in bottle shapes and sizes. The spouts on the far left and right sides are removable, allowing you to hand-fill uniquely shaped bottles that don't fit on the platform. The Ultrafiller 4 is built entirely in stainless steel with PYREX tank, featuring four high efficiency and precision stainless steel filling nozzles. This professional bottling machine is perfect for wine, uncarbonated beer or cider, spirits, and oils. When you place the bottle under the Ultrafiller 4, the fluid is sucked into the vacuum created inside it, without any contact between the liquid and the pumps or mechanical components. Why Choose ILTEC While the Enolmatic has served as a great economical option, the ILTEC offers a significant step up in overall quality and durability. The key differences speak for themselves: Stainless Steel Construction: Unlike the Enolmatic's plastic components, the ILTEC boasts a robust stainless steel construction, ensuring long-lasting performance and easy sanitation. Borosilicate Vacuum Chamber: The ILTEC utilizes a borosilicate vacuum chamber, a superior alternative to the plastic chamber found in the Enolmatic. Borosilicate glass is known for its exceptional resistance to thermal shock and chemical corrosion, guaranteeing a cleaner and more efficient filling process. The ILTEC filler isn't just about superior materials; it's about delivering consistent, precise, and professional results. Whether you're bottling wine, spirits, oils, or other liquids, the ILTEC provides the performance you demand. Specs: Capacity: 500-600 bottles per hour* Bottle Neck Diameter: Standard Spouts: 16-34mm Small Spouts: 9-34mm Bottle Height: Standard Spouts: 7" to 13.75" (180-350mm) Small Spouts: 3.9" to 9.8" (100-250mm) Tank Alcohol Tolerance: 80% ABV Max Temperature: 176°F (80°C) Dimensions: 19.6" x 21.6" 16.5" (500 x 550 x 420mm) Weight: 55.1 lbs Power: 110V, 60hZ, 125W *Capacity may change depending on liquid and bottle size.

$2,899.99

-

ILTEC Ultrafiller 4 | Mixed Spout | Vacuum Bottle Filler | 4 Spout | Pneumatic

Due to high demand, this item is currently out of stock. Be the first to receive your items by placing a pre-order today. We will automatically ship this to you when we receive more in early February. Adjustable filling height with automatic stop Stainless steel base, frame, and filling nozzles Adjustable filling level and filling speed Vacuum gauge Removable spouts for hand filling bottles away from the platform (left-hand and right-hand spouts only) The Mixed Ultrafiller 4 combines 2 standard spouts with 2 two small spouts for the best compromise for those who bottle small batches with a great variety in bottle shapes and sizes. The spouts on the far left and right sides are removable, allowing you to hand-fill uniquely shaped bottles that don't fit on the platform. The Ultrafiller 4 is built entirely in stainless steel with PYREX tank, featuring four high efficiency and precision stainless steel filling nozzles. This professional bottling machine is perfect for wine, uncarbonated beer or cider, spirits, and oils. When you place the bottle under the Ultrafiller 4, the fluid is sucked into the vacuum created inside it, without any contact between the liquid and the pumps or mechanical components. Why Choose ILTEC While the Enolmatic has served as a great economical option, the ILTEC offers a significant step up in overall quality and durability. The key differences speak for themselves: Stainless Steel Construction: Unlike the Enolmatic's plastic components, the ILTEC boasts a robust stainless steel construction, ensuring long-lasting performance and easy sanitation. Borosilicate Vacuum Chamber: The ILTEC utilizes a borosilicate vacuum chamber, a superior alternative to the plastic chamber found in the Enolmatic. Borosilicate glass is known for its exceptional resistance to thermal shock and chemical corrosion, guaranteeing a cleaner and more efficient filling process. The ILTEC filler isn't just about superior materials; it's about delivering consistent, precise, and professional results. Whether you're bottling wine, spirits, oils, or other liquids, the ILTEC provides the performance you demand. Specs: Capacity: 500-600 bottles per hour* Bottle Neck Diameter: Standard Spouts: 16-34mm Small Spouts: 9-34mm Bottle Height: Standard Spouts: 7" to 13.75" (180-350mm) Small Spouts: 3.9" to 9.8" (100-250mm) Tank Alcohol Tolerance: 80% ABV Max Temperature: 176°F (80°C) Dimensions: 19.6" x 21.6" 16.5" (500 x 550 x 420mm) Weight: 55.1 lbs Power: Compressed Air *Capacity may change depending on liquid and bottle size.

$2,799.99

-

ILTEC Ultrafiller 4 Pomodoro | Tomato Sauce | Vacuum Bottle Filler | 4 Spout | 110V

Completely dedicated to thicker liquids, such as tomato sauce Adjustable filling height with automatic stop Stainless steel base, frame, and filling nozzles Adjustable filling level and filling speed Vacuum gauge This filler is the version of the Ultrafiller completely dedicated to denser liquids, such as tomato puree and other sauces. Various modifications applied to the standard machine allow bottles to be filled quickly and easily. Thanks to the larger rubber cone, it is possible to fill both bottles with crown caps and those with screw caps. The pneumatic version is the most powerful machine ever seen on the market—allowing for fast filling even with the thickest sauces. The Ultrafiller Pomodoro is built entirely in stainless steel with PYREX tank, featuring four high efficiency and precision stainless steel filling nozzles. When you place the bottle under the Ultrafiller Pomodoro, the fluid is sucked into the vacuum created inside it, without any contact between the liquid and the pumps or mechanical components. Why Choose ILTEC While the Enolmatic has served as a great economical option, the ILTEC offers a significant step up in overall quality and durability. The key differences speak for themselves: Stainless Steel Construction: Unlike the Enolmatic's plastic components, the ILTEC boasts a robust stainless steel construction, ensuring long-lasting performance and easy sanitation. Borosilicate Vacuum Chamber: The ILTEC utilizes a borosilicate vacuum chamber, a superior alternative to the plastic chamber found in the Enolmatic. Borosilicate glass is known for its exceptional resistance to thermal shock and chemical corrosion, guaranteeing a cleaner and more efficient filling process. The ILTEC filler isn't just about superior materials; it's about delivering consistent, precise, and professional results. Whether you're bottling wine, spirits, oils, or other liquids, the ILTEC provides the performance you demand. Specs: Capacity: 400 x 750mL bottles per hour* Bottle Neck Diameter: 16-34mm Bottle Height: 7" to 13.75" (180-350mm) Tank Alcohol Tolerance: 80% ABV Max Temperature: 176°F (80°C) Dimensions: 19.6" x 21.6" 16.5" (500 x 550 x 420mm) Weight: 55.1 lbs Power: 110V, 60hZ, 125W *Capacity may change depending on liquid and bottle size.

$2,799.99

-

EnoItalia Semimanual Mono Block Filler and Corker | Stainless Trolley Cart | 4 Spout Wine Bottle Filler | 670L/h Fill Rate | Pneumatic Wine Bottle Corker

Semimanual monoblock for filling and corking. The system comes with 4-spout bottle filler and pneumatic corker on a 79" long AISI 304 stainless steel bench on wheels. Bottle Filler The Enoitalia bottle filler is a complete, portable, gravity style bottle filler perfect for a small winery or avid home winemaker. Features four filling heads and stainless steel construction. Fill up to 65 cases of 750ml bottles per hour. This model comes with an electronic level sensor that can be wired to a pump. Compared to units from other Italian manufacturers, this unit has removable filling heads for easy cleaning. The air removal tubes are also larger, which speeds filling. The fill head is also easier to adjust for for bottle fill heights. Features: Adjustable heads are easily removed for cleaning All parts in contact with the wine are made from 304 type stainless steel Level gauge located at the front of the reservoir 15mm diameter filling head Fill height is easily adjustable Larger inner diameter fill head for faster air/gas removal from the bottle for a faster fill rate 670L per hour fill rate 45L reservoir 84 pounds 42" H x 23" W x 20" D Pneumatic Corker Automatic cork loading hopper Cork Diameter: 22-26mm Cork Height: 50mm max Bottle Hieght: 375mm max Corking Time: approx. 3 seconds Made from 304 stainless steel Please Note: The pneumatic corker does not include an air compressor. The advised feeding pressure is 58-65 PSI (4 - 4.5 bar). Manufacturer recomends a compressor of 1.6 gallons (6 liter) or greater with a psi output of 87 psi (6 bar). Do not exceed 116 PSI (8 Bar).

$9,499.99

-

EnoItalia Bag In Box Filler | BB20 | Manual Valve Removal | Vacuum & Nitrogen System | 220V Single Phase

Semi-Automatic Operation: BB20 vacuums, fills, and nitrogen flushes. Operator installs bag and uses built in swing arm with pincer tool to remove and reinstall valve. Perfect for wine, olive oil & more Fill within 5cL CIP cleaning with liquid or steam Touch screen control for easy programming The BB20 is a semi-automatic bag-in-box filler manufactured by Enoitalia in Italy. The beauty of this machine is the simplicity. The BB20 automatically carries out the cycle of vacuuming the bag, filling, and then finally nitrogen flushing. The operator inserts the bag and activates the swing arm pincer tool to remove the valve. After filling the operator again uses the swing arm to quickly reinstall the valve after the bag is filled. The possibility to choose between different types of flow sensors allows the BB20 to be used with liquids of different viscosities, including wine, fruit juices, olive oil and more. Filling can be carried out at room temperature or hot up to 212°F / 100°C. In the case of hot filling, specific accessories are available depending on your set up. A self-priming volumetric pump with rubber impeller is installed as standard. This pump offers a high flow rate, the possibility to prime/draw from any container, an anti-pressure by-pass valve and a total drain valve for emptying the filling circuit. Precision The electric panel allows the control and management of all the filling phases, guaranteeing a repeatability of the volumes filled with an error of ± 5cl. Small corrections can be made if needed. Control Panel The electronic panel allows the control and management of all the filling phases, including volume to fill, time to fill, vacuum time, nitrogen time, management of calibration, and counting of volume. Cleaning Use of a drip-free filling valve Complete emptying of the pipes by means of a drain valve located on the pump Washing CIP circuit with stainless steel tap Preset programs for sanitizing with detergents or for sanitizing with steam 230°F / 110°C (requires the appropriate kit for high temperatures). Other Advantages Structural and mechanical components are made completely in AISI 304 stainless steel Filling head height adjustment with external handwheel Possibility to request adapters for countless types of caps and bags (purch, berker, QCS, QCD, etc.) Inclined stainless steel top to facilitate sanitizing and handling of the bags Multilingual display (Italian, English, French, German, Russian, Spanish, Croatian) Components: PLC panel control touch screen type, multilanguage multiprogram Electromagnetic sensor Burkert type, for cold liquid (like wine / water) Vacuum and Nitrogen system Automatic air piston for blocking the filling head Impeller pump HP 1.5 with by-pass, model EURO 30, capacity 4500 lt/h Quiet, oil-less air 1.5hp air compressor Double start switch Capacity of 1 liter up to 30 liter Semiautomatic hand-wheel for adjusting the filling head’s height Pincer tool to open and close taps. VITOP standard (other on demand) Stainless steel stand with casters SS fitting for cleaning circuit (CIP). Automatic program fo cleaning Total drain valve installed on pump body Fitting connection 1.5" T.C. Specs: 1.5" T.C. connection with 20 mm hose Capacity: 5L bags -- 250 per hour 10L bags -- 180 per hour 20L bags -- 130 per hour Power: 1.1 HP, 220V, 50-60hz, single-phase Dimensions: 23.6" x 32.3" x 63" (600 x 820 x 1600) Weight: 308.6 lbs (140 kg)

$9,499.99

-

EnoItalia Bag In Box Filler | BB30 | Automated Valve Removal | Vacuum & Nitrogen System | 220V Single Phase

Semi-Automatic Operation: BB30 vacuums, fills, and nitrogen flushes. Operator installs bag and the machine automatically removes valve, fills, and reinstalls valve. Perfect for wine, olive oil & more Fill within 5cl CIP cleaning with liquid or steam Touch screen control for easy programming The BB30 a semi-automatic bag-in-box filler manufactured by Enoitalia in Italy. The beauty of this machine is the simplicity. The BB30 automatically carries out the cycle of vacuuming the bag, filling, and then finally nitrogen flushing. The operator inserts the bag and activates the machine to remove the valve, fill the bag, and reinstall the valve in one smooth, seamless operation. The possibility to choose between different types of flow sensors allows the BB30 to be used with liquids of different viscosities, including wine, fruit juices, olive oil and more. Filling can be carried out at room temperature or hot up to 212°F / 100°C. In the case of hot filling, specific accessories are available depending on your set up. A self-priming volumetric pump with rubber impeller is installed as standard. This pump offers a high flow rate, the possibility to prime/draw from any container, an anti-pressure by-pass valve and a total drain valve for emptying the filling circuit. Precision The electric panel allows the control and management of all the filling phases, guaranteeing a repeatability of the volumes filled with an error of ± 5cl. Small corrections can be made if needed. Control Panel The electronic panel allows the control and management of all the filling phases, including volume to fill, time to fill, vacuum time, nitrogen time, management of calibration, and counting of volume. Cleaning Use of a drip-free filling valve Complete emptying of the pipes by means of a drain valve located on the pump Washing CIP circuit with stainless steel tap Preset programs for sanitizing with detergents or for sanitizing with steam 230°F / 110°C (requires the appropriate kit for high temperatures). Other Advantages Structural and mechanical components are made completely in AISI 304 stainless steel Filling head height adjustment with external handwheel Possibility to request adapters for countless types of caps and bags (purch, berker, QCS, QCD, etc.) Inclined stainless steel top to facilitate sanitizing and handling of the bags Multilingual display (Italian, English, French, German, Russian, Spanish, Croatian) Components: PLC panel control touch screen type, multilanguage multiprogram Electromagnetic sensor Burkert type, for cold liquid (like wine / water) Vacuum and Nitrogen system Automatic air piston for blocking the filling head Impeller pump HP 1.5 with by-pass, model EURO 30, capacity 4500 lt/h Quiet, oil-less air 1.5hp air compressor Double start switch Capacity of 1 liter up to 30 liter Semiautomatic hand-wheel for adjusting the filling head’s height Automated removal and reinstallation of the bag valve. VITOP standard (other on demand) Stainless steel stand with casters SS fitting for cleaning circuit (CIP). Automatic program fo cleaning Total drain valve installed on pump body Fitting connection 1.5" T.C. Specs: 1.5" T.C. connection with 20 mm hose Capacity: 3L bags -- 450 per hour 5L bags -- 300 per hour 10L bags -- 240 per hour 20L bags -- 180 per hour Power: 2 HP, 220V, 50-60hz, single-phase Dimensions: 31.5" x 39.4" x 59" (800 x 1000 x 1500) Weight: 308.6 lbs (140 kg)

$16,499.99

-

EnoItalia Bag In Box Filler | BB50 | Fully Automatic Filling & Conveyor System | 380V Three Phase

Fully automatic operation: BB50 pulls in bag film, fills, cuts bag, and feeds down conveyor belt for packaging Bag valve is automatically removed and reinstalled during the vacuum filling process In addition to wine, it can be configured for olive oil, creams, sauces, soaps, and other industrial liquids Automatic motorized conveyor at end point where bags are dropped through the hopper into boxes Touchscreen control panel installed in stainless steel enclosure on rolling casters The BB50 is a fully automatic bag-in-box filler manufactured by EnoItalia in Italy. The most advanced model of EnoItalia’s bag-in-box fillers, the BB50 automatically feeds bags into its vacuum filling system, cuts and separates the bags, and feeds them down a conveyor for box packaging. The system consists of three modules – the filling machine itself, a stainless steel enclosed control panel, and a motorized roller conveyor where boxes receive the filled bags. The possibility to choose between different types of flow sensors allows the BB30 to be used with liquids of different viscosities, including wine, fruit juices, olive oil and more. Filling can be carried out at room temperature or hot up to 212°F / 100°C. In the case of hot filling, specific accessories are available depending on your set up. A self-priming volumetric pump with rubber impeller is installed as standard. This pump offers a high flow rate, the possibility to prime/draw from any container, an anti-pressure by-pass valve and a total drain valve for emptying the filling circuit. If you will install a filter station before the filler, it is recommended to install a buffer tank in between the filter and the filler. Two options are available: the Atmospheric Tank and the Isobaric Tank. The Atmospheric Tank is a simple solution, 200L in size with internal level sensor and external control for a pump. The Isobaric Tank is a more professional 100L automatic buffer tank that uses nitrogen to push liquid into the filler. With this configuration, the BB50 will not include the pump, and the control panel will have an automatic program to set the pressure used during filling or washing. Precision: The Autotuning function allows automatic calibration of the machinery, eliminating the need to carry out countless samples. Repeatability of volumes with an error of ± 0.2%. Control Panel: The Siemens PLC control panel allows you to manage all the filling phases, adapting the machine to any type of liquid treated (wine, fruit juices, oil, water, creams, etc.). From the touch screen control panel, you can program and manage the filling cycle, adjust working speed, calibrate dosages, and execute washing and sanitizing operations. Cleaning: The machine can be sanitized with a CIP circuit using the special stainless steel tap and the automatic program. Furthermore, the BB50 is designed to perform 230°F / 110°C steam sanitization. Other Advantages: Structural and mechanical components are made completely in AISI 304 stainless steel Equipped with a 9500 L/h self-priming volumetric pump with rubber impeller and speed regulation inverter Possibility to request adapters for countless types of caps and bags (purch, berker, QCS, QCD, etc.) Multilingual display (Italian, English, French, German, Russian, Spanish, Croatian) Components: Siemens PLC panel control w/ 7" touchscreen Remote assistance kit with LAN connection Control panel installed on stainless steel cart with rolling casters, 16' cable connection Automatic separation of bags Self-priming electric pump with rubber impeller - 9,300 L/h, 900 RPM Electronic speed variator for pump Vacuum filling system Continuous filling of bags with VITOP tap (other taps on demand) SS fitting for cleaning circuit (CIP). Automatic program fo cleaning Total drain valve installed on pump body Specs: 1.5" T.C. connection Capacity: 3L bags -- 500 per hour 5L bags -- 480 per hour 10L bags -- 280 per hour 20L bags -- 200 per hour Power: 2.5 HP, 380V, 50hz, three-phase 5 poll Dimensions: 130" x 44" x 99" (3300mm x 1100mm x 2500mm) Weight: 1,433 lbs (650 kg)

$72,999.99