Freight Only

-

EnoItalia Bag In Box Filler | BB12 | Semi Automatic Filling | Built-In Rubber Impeller Pump | Stainless Support Stand | 220V Single Phase

Semi-Automatic Operation: BB12 performs filling cycle automatically. Operator installs bag and uses built in swing arm with pincer tool to remove and reinstall valve. Perfect for smaller wineries with capacity to fill up to 150 x 5L bags per hour Fill within 5cL CIP cleaning circuit Control panel for operating built-in Euro 20 pump The BB20 is a semi-automatic bag-in-box filler manufactured by Enoitalia in Italy. The BB12 automatically carries out the filling cycle with the use of the built-in control panel and pump. An injection valve allows manual injection of inert gas at the end of the cycle. The operator inserts the bag and activates the swing arm pincer tool to remove the valve. After filling the operator again uses the swing arm to quickly reinstall the valve after the bag is filled. The platform is made entirely of stainless steel with 4 adjustable feet and is compact enough to fit on a work bench where the system will be at a comfortable height for the operator. Precision The electric panel allows the control and management of all the filling phases, guaranteeing a repeatability of the volumes filled with an error of ± 5cl. Small corrections can be made if needed. Cleaning Use of a drip-free filling valve Complete emptying of the pipes by means of a drain valve located on the pump Washing CIP circuit with stainless steel tap Components: Panel control with PLC to program capacity and calibration Digital flow meter Stainless steel filling head Inert gas injection valve Impeller pump HP 0.5, model EURO 30, capacity 1000 lt/h Capacity of 1 liter up to 20 liter Pincer tool to open and close taps. VITOP standard (other on demand) Stainless steel desk with adjustable legs SS fitting for cleaning circuit (CIP) Specs: Capacity: 3L bags -- 180 per hour 5L bags -- 150 per hour 10L bags -- 100 per hour 20L bags -- 40 per hour Power: 0.5 HP, 220V, 50-60hz, single-phase Dimensions: 29.1" x 35.4" x 28.3" (740x900x720) Weight: 110.2 lbs (50 kg)

$4,499.99

-

EnoItalia Apple Belt Press

The EnoItalia single belt presses are a modern design that allows for continuous, efficient processing of crushed fruit. Most often used with apples but suitable for other fruits and vegetables as well. With apples, the juice yield is approximately 75%. Enoitalia Belt Presses are often integrated with a separate Enoitalia fruit washer and loader that washes the apples and then loads them systematically into the belt press. The washer/loader, connected to the belt press by electronic cable, is turned off and on to maintain a consistent supply of fruit. Features: PVC belt pressing against drums provides 75% efficiency Includes an innovative integrated pump and juice collection tank, saving money and reducing complexity Juice collection tank features an integrated filtration sieve providing clearer and purer product The belt presses work automatically: when the mash inlet tank is full, all other machines which come before the belt press turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks The belt press includes a high-pressure washer, which continuously washes the machine's belt. The belt washing system is simple, and does not contain any engines or reducers, so it prolongs the use time and saves on service cost The safety cover can be easily opened which makes the washing process of the machine easier. The 800 & 1200 models include a pneumatic opening because of the cover size. After use, the belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools Adjustable belt tension Frame is made of stainless steel with adjustable feet Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble For more information, contact our Sales Team today.

$27,999.99

-

EnoItalia Tank Washing System | Stainless Centrifugal Pump & Washing Slide | 52 GPM | 220V Single Phase

Perfect for wine tanks where a built-in or top-mounted spray ball is not an option Place the stainless steel washing slide inside your tank and connect the tank outlet to the inlet of the pump The pump will deliver 52 gallons per minute at 36 PSI Ideal for tanks with a maximum height of 10 feet A simple, yet effective, high pressure washing system for wine tanks where a built-in or top-mounted spray ball is not an option. The washing system includes a high-pressure pump and a stainless steel washing slide. The washing slide is connected to the outflow of the pump and placed in the middle of the tank with the hose snaking through the manway door. Then the bottom outlet of the tank is connected to inflow of the pump to create a cleaning circuit. The stainless centrifugal pump delivers 52 gallons per minute with 2.5 BAR of pressure and features 2" T.C. outlet and 1.5" T.C. outlet. Includes stainless steel washing slide with 1.5" T.C. connection. Specs: Ideal for tanks with a max height of 10 ft Flow Rate: 52 GPM at 36 psi Inlet: 2" tri-clamp Outlet: 1.5" tri-clamp Power: 220V Single Phase, 2 HP

$2,499.99

-

EnoItalia Gamma Horizontal Press | Pneumatic Membrane Press | Stainless | 220V 3 Phase

The Gamma series pneumatic side membrane press is the ideal solution for obtaining superior product in the pressing of both freshly harvested grapes and fermented must. The presses are completely made of stainless steel, with a large central opening to facilitate both filling and emptying. The technology used allows the management of each pressing phase the highest quality output. PLC Screen Control Using the PLC screen you have access to 12 preset and 12 custom pressing programs as well as a fully manual option. The manual function allows for control of the drum rotation, compressor, and fan. The PLC touchscreen allows for individual control or you can utilize one of the 12 present programs. Want to customize the pressing cycle to your requirements? Save your parameters into one of the 12 available custom program slots. Sealed Drum This is a closed cylinder press which reduces oxidation during the pressing cycle to help ensure quality. Pressed juice exits the drum via drainage channels that are covered with slotted stainless steel screens. The very highest-end commercial presses use a similar closed cylinder system. The Gamma is easily cleaned at the end of the session by easily removing the internal drain channel screens, without the need for tools, through the wide access doors. An additional benefit of the sealed drum is that it is possible to use the press for all or part of a fermentation. Buffer Tank with Level Sensor The Gamma presses include a buffer tank with level sense at the bottom of the press. Via a separate control panel, an external single-phase Enotialia pump (not included) can be connected to turn off and on to move wine from the buffer tank into your storage tanks. The outlet of the buffer tank is 1.5" Tri-Clamp. Axial Load Valve All Gamma presses come standard with a 3" axial loading ball valve port on the cylinder that allows must to be pumped in. We consider this an essential feature on a press otherwise you are limited to dumping or pumping in through the top access doors. Pumping in through the bottom increases the volume you fit into the drum and reduces oxidation. Cleaning With the drain channel screens removed by hand the unit is easily washed internally from the large hatch doors. On very large presses there is a need for internal washing systems but on presses of this size they are easily washed through the large hatch access doors. Gamma presses have two drum drains for easier cleaning. A standard drain and then the 3" axial load valve acts as a second drain. Benefits: Simple controls Easy operations Completly Automated or Manual operation Features: Closed cylinder with drain canal / open perforated cylinder Double central sliding doors Collection tank conical floor with stainless valve for drain and filter Coaxial loading ball valve Control panel with PLC, and 5 automatic programs Manual mode Berker brand blade compressor Double fan for suction and inflation max 0.2 bar Rolling casters Stainless steel construction Safety cord for emergency stop Panel control with emergency stop 220V 60hz 3 Phase (neutral + 3 poles + ground)

$26,499.99

-

Speidel Storage Tank | Laser-Welded | Stainless Steel | 525L

Please note: the primary image is an example image and does not exactly match this tank. See below for features and specifications. Premium quality laser-welded 304 stainless steel closed tank Made in Germany by Speidel and backed by a 25-year warranty Ideal for spirits and fermented beverages like wine, beer, cider, and kombucha. Ultra-smooth 2R interior finish allows for easy cleaning with cold water 1.5” tri-clamp ports with two additional DIN ports for included thermometer/thermowell combo and sample valve The top lid provides a convenient opening for additions and the legs provide easy access to the bottom ports Vaulted complete drainage bottom for maximum product yield and easy cleaning We are proud to present these FD storage tanks made of premium quality 304 stainless steel. Built in Germany by Speidel and sold exclusively in the USA by MoreWine! Pro for over 20 years, the world-class traditions of German engineering and craftsmanship are reflected in these tanks. And, after examining tanks built by every major manufacturer worldwide, we can safely say that when it comes to features, quality, and price, these tanks represent the very best value available in stainless steel beer storage. Safely store small volumes of product in these beautiful tanks. The legs make accessing the ports easy and the convenient top hatch makes cleaning a dream when combined with the 2R interior finish. Heavy-duty sealing mechanism and gasket form a seal on top with a stainless steel lid equipped with a T.C. port for adding accessories or an airlock. The inside is finished to Speidel quality standards with flawless welds and a 2R finish. The tanks will support a few PSI of pressure, however, they are not pressure-rated or designed to be used under pressure. Tank Ports Tanks feature 1.5" T.C. outlets (1 on bottom for complete drainage, one in middle for racking arm, one on top for blowoff/airlock), and also two welded DIN fittings. One DIN port is equipped with an included sample valve and the other has an included thermometer and thermowell combination. Speidel Quality Features Interior Finish - Speidel tanks feature an ultra-smooth 2R interior surface which allows you to clean your tanks with cold water, without scrubbing. This saves significant labor costs. Weld Quality - Speidel's robotic-arm laser welders create flawless stainless-to-stainless junctions that look and feel more like a taped fabric seam than a traditional weld. Ultra high-quality welds leave no chance for residual products to harbor spoilage organisms. Warranty - Speidel and MoreWine! Pro back up each and every tank with an industry-leading 25-year warranty against defects in materials or workmanship. Thickness - Speidel tanks are on average around 25% thicker than Italian-manufactured tanks of the same general capacity and dimensions. Complete Drainage Bottoms - These tanks are outfitted with vaulted bottoms for total drainage, which maximizes product yield at racking and makes cleaning a snap. Tank Features: Full Volume of 525 L (138 gal) Perfect for blending two barrels of wine 1.5" T.C. Drain, Racking Port, and Lid outlet 8.5" Top hatch for easy cleaning and additions 2 X DIN10 Fittings w/ Sample Valve and Thermowell/Thermometer combo Tank Dimensions: 820mm D x 1466mm H (32.25" D x 57.7" H)

$2,199.99 $1,539.99

-

Speidel Storage Tank | Laser-Welded | Stainless Steel | 240L

Please note: the primary image is an example image and does not exactly match this tank. See below for features and specifications. Premium quality laser-welded 304 stainless steel closed tank Made in Germany by Speidel and backed by a 25-year warranty Ideal for spirits and fermented beverages like wine, beer, cider, and kombucha. Ultra-smooth 2R interior finish allows for easy cleaning with cold water 1.5” tri-clamp ports with two additional DIN ports for included thermometer/thermowell combo and sample valve The top lid provides a convenient opening for additions and the legs provide easy access to the bottom ports Vaulted complete drainage bottom for maximum product yield and easy cleaning We are proud to present these FD storage tanks made of premium quality 304 stainless steel. Built in Germany by Speidel and sold exclusively in the USA by MoreWine! Pro for over 20 years, the world-class traditions of German engineering and craftsmanship are reflected in these tanks. And, after examining tanks built by every major manufacturer worldwide, we can safely say that when it comes to features, quality, and price, these tanks represent the very best value available in stainless steel beer storage. Safely store small volumes of product in these beautiful tanks. The legs make accessing the ports easy and the convenient top hatch makes cleaning a dream when combined with the 2R interior finish. Heavy-duty sealing mechanism and gasket form a seal on top with a stainless steel lid equipped with a T.C. port for adding accessories or an airlock. The inside is finished to Speidel quality standards with flawless welds and a 2R finish. The tanks will support a few PSI of pressure, however, they are not pressure-rated or designed to be used under pressure. Tank Ports Tanks feature 1.5" T.C. outlets (1 on bottom for complete drainage, one in middle for racking arm, one on top for blowoff/airlock), and also two welded DIN fittings. One DIN port is equipped with an included sample valve and the other has an included thermometer and thermowell combination. Speidel Quality Features Interior Finish - Speidel tanks feature an ultra-smooth 2R interior surface which allows you to clean your tanks with cold water, without scrubbing. This saves significant labor costs. Weld Quality - Speidel's robotic-arm laser welders create flawless stainless-to-stainless junctions that look and feel more like a taped fabric seam than a traditional weld. Ultra high-quality welds leave no chance for residual products to harbor spoilage organisms. Warranty - Speidel and MoreWine! Pro back up each and every tank with an industry-leading 25-year warranty against defects in materials or workmanship. Thickness - Speidel tanks are on average around 25% thicker than Italian-manufactured tanks of the same general capacity and dimensions. Complete Drainage Bottoms - These tanks are outfitted with vaulted bottoms for total drainage, which maximizes product yield at racking and makes cleaning a snap. Tank Features: Full Volume of 240 L (63.4 gal) Perfect for blending two barrels of wine 1.5" T.C. Drain, Racking Port, and Lid outlet 8.5" Top hatch for easy cleaning and additions 2 X DIN10 Fittings w/ Sample Valve and Thermowell/Thermometer combo Tank Dimensions: 550mm D x 1524mm H (21.6" D x 60" H)

$1,429.99

-

Speidel Storage Tank | Laser-Welded | Stainless Steel | 100L

Please note: the primary image is an example image and does not exactly match this tank. See below for features and specifications. Premium quality laser-welded 304 stainless steel closed tank Made in Germany by Speidel and backed by a 25-year warranty Ideal for spirits and fermented beverages like wine, beer, cider, and kombucha. Ultra-smooth 2R interior finish allows for easy cleaning with cold water 1.5” tri-clamp ports with two additional DIN ports for included thermometer/thermowell combo and sample valve The top lid provides a convenient opening for additions and the legs provide easy access to the bottom ports Vaulted complete drainage bottom for maximum product yield and easy cleaning We are proud to present these FD storage tanks made of premium quality 304 stainless steel. Built in Germany by Speidel and sold exclusively in the USA by MoreWine! Pro for over 20 years, the world-class traditions of German engineering and craftsmanship are reflected in these tanks. And, after examining tanks built by every major manufacturer worldwide, we can safely say that when it comes to features, quality, and price, these tanks represent the very best value available in stainless steel beer storage. Safely store small volumes of product in these beautiful tanks. The legs make accessing the ports easy and the convenient top hatch makes cleaning a dream when combined with the 2R interior finish. Heavy-duty sealing mechanism and gasket form a seal on top with a stainless steel lid equipped with a T.C. port for adding accessories or an airlock. The inside is finished to Speidel quality standards with flawless welds and a 2R finish. The tanks will support a few PSI of pressure, however, they are not pressure-rated or designed to be used under pressure. Tank Ports Tanks feature 1.5" T.C. outlets (1 on bottom for complete drainage, one in middle for racking arm, one on top for blowoff/airlock), and also two welded DIN fittings. One DIN port is equipped with an included sample valve and the other has an included thermometer and thermowell combination. Speidel Quality Features Interior Finish - Speidel tanks feature an ultra-smooth 2R interior surface which allows you to clean your tanks with cold water, without scrubbing. This saves significant labor costs. Weld Quality - Speidel's robotic-arm laser welders create flawless stainless-to-stainless junctions that look and feel more like a taped fabric seam than a traditional weld. Ultra high-quality welds leave no chance for residual products to harbor spoilage organisms. Warranty - Speidel and MoreWine! Pro back up each and every tank with an industry-leading 25-year warranty against defects in materials or workmanship. Thickness - Speidel tanks are on average around 25% thicker than Italian-manufactured tanks of the same general capacity and dimensions. Complete Drainage Bottoms - These tanks are outfitted with vaulted bottoms for total drainage, which maximizes product yield at racking and makes cleaning a snap. Tank Features: Full Volume of 100 L (26.4 gal) Perfect for blending two barrels of wine 1.5" T.C. Drain, Racking Port, and Lid outlet 8.5" Top hatch for easy cleaning and additions 2 X DIN10 Fittings w/ Sample Valve and Thermowell/Thermometer combo Tank Dimensions: 440mm D x 1141mm H (17.3" D x 45" H)

$1,099.99

-

EnoItalia Lobe Pump | Programmable EuroFill Lobe Rotor Pump | Motorized Receiving Hopper | 7.5 kW | 220V

All the programmable benefits of the EuroFill pumps Perfectly machined stainless steel lobe rotors Ideal for pushing wine through plate and frame, lenticular, and/or cartridge filters Dry stop protection Wireless remote Motorized receiving hopper included The ultimate one winery pump for all applications The Lobe Rotor pump from EnoItalia is the ultimate winery pump, representing the best of all worlds. Combines all the major benefits of the EuroFill pump, via the programmable PLC, with all the benefits of a Lobe Rotor pump. Lobe Rotor pumps can also be used for filtering applications where positive pressure is necessary to pump wine through a sheet or membrane. Lobe Rotor pumps also have some of the lowest shear values which protects skins and seeds from being macerated during the pumping process. The 'smart' component is what sets this EnoItalia pump apart from other lobe rotor pumps. The built-in programmed logic controller brain allows you to know the volume pumped during any transfer. You can also program the volume you wish to transfer. The potential applications are unlimited. Program the pump to fill a barrel. Create perfect blends. Do timed pump overs. Includes the optional receiving hopper that can be used under a destemmer crusher to collect whole destemmed, or crushed grapes. Max capacity 50,700 lbs with destemmed grape, and 44,000 lbs with fermented grape. Benefits: The only pump you will need in your winery that allows you to use if for all applications. The highest quality, lowest shear value keeps skins and seeds intact to reduce unwanted tannin. The smartest plc brain for programmed volume transfers. This is the ultimate winery pump. Positive pressure allows for use in filtering applications Motorized receiving hopper included Features: Speed control Timed and programmable volume pumping Dry stop protection - pump turns off to protect pump when dry Direction reversal Pressure switch Connection for a motorized collection buffer Wireless remote control Easy to use PLC programmable controls Low profile and easily moved 3" tri-clamp inlet/outlet 3" DIN connector for hopper included 220v 60hz 3 Phase 7.5 kW Receiving hopper: 220v 3 Phase 0.75 kW

$33,999.99

-

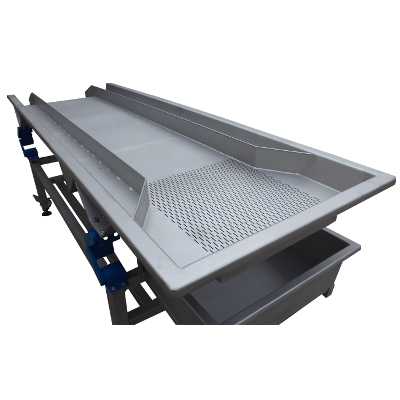

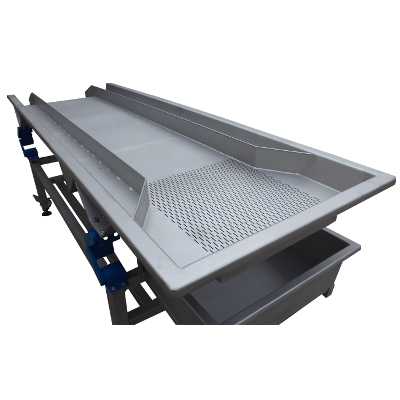

EnoItalia Vibrating Sorting Table | Variable Speed Control | Jolly Reverse Series Crusher Destemmers

Pairs perfectly with the EnoItalia Jolly 60 and Jolly 180 Reverse series crusher destemmers Position the selection table below the Jolly Reverse unit to receive grapes for further sorting and quality control Vibrating action evenly spreads grapes on the table surface for easy visual inspection Raisins, underripe grapes, moldy grapes, etc. are removed by hand so you end up with the best must possible for winemaking Features variable speed control, rolling casters, and height-adjustable legs Vibrating sorting tables are considered the gold standard of sorting, allowing you to make the very highest quality wine from your grapes. They are amazing for removing raisins, underripe grapes, moldy grapes, etc in addition to all MOG (Matter Other than Grapes) such as stems, leaves, and any other foreign material. While they offer the potential of immaculately clean must you do need at least two quick people to work the sorting table. If labor is an issue, consider our Jolly 60 Reverse with Built-in Automatic Sorting Table. While the auto sort will not reach the absolute pinnacle of pristine fruit that a vibrating sorting table with great labor can, great labor is getting harder to find! The Vibrating Selection Table pairs perfectly with the EnoItalia Jolly 60 and Jolly 180 Reverse series crusher destemmers. The table is made entirely of 304 stainless steel with a micro-shot peening surface treatment. Position the table below the Jolly Reverse unit to receive grapes for further sorting and quality control. Grapes drop down onto a slotted area where oxidized juice and seeds are automatically dropped into a collection pan. From there the vibrating action evenly spreads grapes on the table surface for easy visual inspection where moldy, damaged grapes, raisins, stems, leaves or any debris that made it through the destemmer can be removed by hand. The support frame is equipped with 4 swivel casters, telescopic legs that can be adjusted to three different height positions, and 4"-high product containment side rails. The constant advancement of grapes down the sorting table is enabled by the use of two 0.37 kW vibrating motors that cause grapes to 'dance' down the table. The operating portion of the table is 31.5" wide by 10' long. A removable grate complete with DN 50 connection allows the elimination of liquid from the slotted discharge area. As standard, it is supplied complete with a CE-compliant electrical panel and an electronic speed variator. Grapes can either gravity drop off into a waiting collection bin or an optional EnoItalia grape crusher, along with must pump, can be placed at the end of the sorting table. Inquire with our sales staff for more information. Specs: Internal Width: 31.5" Table Length: 10 ft. Capacity: 2-10 ton/h 1.5 kW

$19,499.99

-

EnoItalia Screw Elevator U-200 | Variable Speed Control | Loading Hopper | Height-Adjustable Trolley | 220V Single Phase

The U-200 Screw Elevator built entirely in stainless steel, is a multi-purpose machine that allows the transport of whole grapes inside the destemmer, the pomace to the press, or the evacuation of the stems from the unloading area of the destemmer. The low rotation speeds and included speed variator allow non-aggressive handling of the grapes. A height-adjustable stainless steel trolley is supplied as standard. Loading hopper with side pump connection for liquid recovery. 2HP single-phase motor with CE emergency stop. Features: Stainless screw feed 7.8" Diameter x 118" L Variable Speed with Frequency Drive Loading hopper with connection fitting for liquid Open cover lid for cleaning Winch to adjust the height Capacity: 2-10 tons per hour Hopper Dimensions: 25.5" x 28.3" x 35.4" Loading Height: 18.9" to 27.9" Discharge Height: 63" to 78" 220V Single Phase 2HP Motor CE panel control

$9,899.99

-

EnoItalia Jolly 180 Reverse Crusher Destemmer | Electronic Speed Control | Automatic Cleaning System | Stainless Steel | 20 tons/h | 220V 3 Phase

Independently controlled feeding hopper and destemming basket Destemming chamber/basket with anti-tear design is gentle on grapes to reduce skin abrasion Unique chamber-mounted wiper cleanly moves destemmed grapes to the exit 20 tons per hour processing capacity Integrated washing system for quick cleanings between varietals or after an extended break Made in Italy by EnoItalia The Jolly 180 Reverse Destemmer from our partners at EnoItalia features three adjustable speed motors to allow for independent control of the feeding hopper, the destemming process, and the roller group. Along with adjustability in the destemming bar and then on gap setting in the sorting process you can really dial in the machine for your application. Jolly 180 Reverse EnoItalia's newest destemmer, the Jolly 180 Reverse is the ideal processing unit for smaller wineries looking for top-quality processing at an affordable price. The loading hopper features a mechanical speed variable motor so you can control the flow of grape bunches into the destemming chamber. The destemming bar and basket are separately controlled by a variable frequency drive that allows you to turn a dial to set the right speed. Separate control of these processes allows you to find the balance between speed and quality and helps the machine from being overloaded at either stage. The destemming chamber is made with a gentle anti-tear design to reduce grape skin abrasion. The holes in the basket are deep punched through thicker stainless steel, from the inside out, and then bead blasted to remove any sharp edges. The destemming bar features fingers with adjustable rubber tips to ensure a gentle touch on your grapes. The destemming chamber and the destemming bar move in opposite or "reverse" direction for best performance. The receiving hopper features perforated drainage holes to allow juice, sometimes found in the bottom of picking bins, to exit before entering the destemming chamber. There is a 1.5" hose barb for connecting tubing that runs into a collection bucket. That juice is most often discarded. Optional Accessories: The Jolly Reverse can be custom ordered with the below accessories. Contact our Sales Team today to inquire. Collection Tank with Central Screw & Motor - WE540 Larger Hopper for Macrobin use - WE541 Jolly 180 Reverse: 304 Stainless Steel Construction Process up to 20 tons per hour 220V 3 Phase 7HP Motor Variable Speed with Frequency Drive Rubber Tipped Destemming bars Centrifugal Destmming chamber rotates in reverse direction of destemming bar Unique chamber-mounted wiper blade cleanly moves grapes to discharge port Destemming chamber features 24mm holes Casters, 2 of which lock Easily remove destemming chamber/basket and shaft for easy cleaning Unit comes with bare cord wire. Wire on the appropriate 220V plug for your electrical connection Manufactured by EnoItalia Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$24,999.99

-

EnoItalia Jolly 60 Reverse Crusher Destemmer | Electronic Speed Control | Automatic Cleaning System | Stainless Steel | 6 tons/h | 220V Single Phase

Independently controlled feeding hopper and destemming chamber Destemming chamber/basket with anti-tear design is gentle on grapes to reduce skin abrasion Unique chamber-mounted wiper cleanly moves destemmed grapes to the exit 6 tons per hour processing capacity Integrated washing system for quick cleanings between varietals or after an extended break Made in Italy by EnoItalia The Jolly 60 Reverse Destemmer from our partners at EnoItalia features three adjustable speed motors to allow for independent control of the feeding hopper, the destemming process, and the roller group. Along with adjustability in the destemming bar and then on gap setting in the sorting process you can really dial in the machine for your application. Jolly 60 Reverse EnoItalia's newest destemmer, the Jolly 60 Reverse is the ideal processing unit for smaller wineries looking for top-quality processing at an affordable price. The loading hopper features a mechanical speed variable motor so you can control the flow of grape bunches into the destemming chamber. The destemming bar and basket are separately controlled by a variable frequency drive that allows you to turn a dial to set the right speed. Separate control of these processes allows you to find the balance between speed and quality and helps the machine from being overloaded at either stage. The destemming chamber is made with a gentle anti-tear design to reduce grape skin abrasion. The holes in the basket are deep punched through thicker stainless steel, from the inside out, and then bead blasted to remove any sharp edges. The destemming bar features fingers with adjustable rubber tips to ensure a gentle touch on your grapes. The destemming chamber and the destemming bar move in opposite or "reverse" direction for best performance. The receiving hopper features perforated drainage holes to allow juice, sometimes found in the bottom of picking bins, to exit before entering the destemming chamber. There is a 1.5" hose barb for connecting tubing that runs into a collection bucket. That juice is most often discarded. Optional Accessories: The Jolly Reverse can be custom ordered with the below accessories. Contact our Sales Team today to inquire. Collection Tank with Central Screw & Motor - WE540 Larger Hopper for Macrobin use - WE541 Jolly 60 Reverse: 304 Stainless Steel Construction Process up to 6 tons per hour 220V Single Phase 3HP Motor Variable Speed with Frequency Drive Rubber Tipped Destemming bars Centrifugal Destmming chamber rotates in reverse direction of destemming bar Unique chamber-mounted wiper blade cleanly moves grapes to discharge port Destemming chamber features 24mm holes Casters, 2 of which lock Easily remove destemming chamber/basket and shaft for easy cleaning Unit comes with bare cord wire. Wire on the appropriate 220V plug for your electrical connection Manufactured by EnoItalia Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$13,499.99 $8,099.99

-

EnoItalia Lobe Pump | Lobe Rotor Pump | 7.5 kW | 220V

Ideal for pushing wine through plate and frame, lenticular, and/or cartridge filters Ideal for moving must and wine Dry stop protection Wireless remote Optional motorized receiving hopper for placement under a destemmer (shown in photo) The ultimate one winery pump for all applications The Lobe Rotor pump from EnoItalia is the ultimate winery pump, representing the best of all worlds. Lobe Rotor pumps can also be used for filtering applications where positive pressure is necessary to pump wine through a sheet or membrane. Lobe Rotor pumps also have some of the lowest shear values which protects skins and seeds from being macerated during the pumping process. The stainless lobe rotos are coated in rubber to ensure that seeds to do not get marcerated in the pumping process. Enoitalia also makes an optional receiving hopper that can be used under a destemmer crusher to collect whole destemmed, or crushed grapes. Max capacity 50,700 lbs with destemmed grape, and 44,000 lbs with fermented grape. Benefits: The only pump you will need in your winery that allows you to use if for all applications. The highest quality, lowest shear value keeps skins and seeds intact to reduce unwanted tannin. Positive pressure allows for use in filtering applications Optional receiving hopper availlable Features: PLC interface Speed control Timed and programmable volume pumping Dry stop protection - pump turns off to protect pump when dry Direction reversal Pressure switch Connection for a motorized collection buffer Wireless remote control Easy to use PLC programmable controls Low profile and easily moved 3" tri-clamp inlet/outlet 220v 60hz 3 Phase 7.5 kW

$17,599.99

-

MB® Filter Tank for Cold Brew Coffee System | 50L | 13.2 Gallons

Provides an extra layer of filtration for clearer cold brew Tilting design allows for easy removal of sediment and simplifies cleaning Mobile stainless steel cart with locking wheels for convenient movement The optional filter tank is designed for seamless integration with the MB Cold Brew Coffee System. This unit provides an additional stage of filtration as liquid is transferred from the brewing system to a fermenter or holding tank. It features a removable 6.5-micron filter screen for effective particulate removal. The tank's tiltable design facilitates efficient solid removal and simplifies post-use cleaning. Integrated components include a pressure gauge for monitoring filtration pressure and a tri-clamp sight glass for visual clarity assessment. The filter tank is mounted on a robust stainless steel cart frame equipped with four locking casters, ensuring ease of mobility within your facility. Features: Tiltable filter tank 3mm thick tank body 6.5-micron filter mesh Pressure gauge Sight glass Rolling casters with brakes Tri-clamp fittings included

$5,499.99

-

MB® Hop Back Tank | Hop or Fruit Infuser | 1.5" T.C. Sanitary Ports | Fittings Included | 1 BAR PRV | Stainless Steel | 100L | 26.4G

Large infusion basket allows for easy addition of whole hops, fruit, or other flavorings Side outlet port separates sediment, ensuring a cleaner final product Fine mesh screen within the perforated basket maximizes infusion efficiency Infusing hops or fruit has never been easier. This 100L tank has a large basket to hold whole hops, pellet hops, fruit or anything else you need to infuse into your beer. There is a side outlet port above the bottom dump so any sediment is separated. The basket is made from perforated plate with a fine mesh screen. The basket measures 15 Ø x 17.5 tall and holds 13.4 gallons (50L). Specs: Made from 304 stainless steel 26.4 gal (100L) 1.5" tri-clamp ports Fittings included (3) 1.5" Butterfly Valves w/ clamps & gaskets (1) 1.5" T.C. PRV (1 BAR) Please Note: The Hop Back Tank now comes with pull handle butterfly valves rather than the blue plastic trigger handle valves show in the photos.

$2,749.99 $1,649.99

-

EnoItalia Bag In Box Filler Buffer Tank | Isobaric Tank | 100L

The 200L Atmospheric Tank is intended to be sold as an accessry to the BB50 Bag In Box filler. If you will install a filter station before the filler, it is recommended to install a buffer tank in between the filter and the filler. Two options are available: the Atmospheric Tank and the Isobaric Tank. The Isobaric Tank is a more professional 100L automatic buffer tank that uses nitrogen to push liquid into the filler. With this configuration, the BB50 will not include the pump, and the control panel will have an automatic program to set the pressure used during filling or washing.

$12,499.99

-

EnoItalia Bag In Box Filler Buffer Tank | Atmospheric Tank | 200L

The 200L Atmospheric Tank is intended to be sold as an accessry to the BB50 Bag In Box filler. If you will install a filter station before the filler, it is recommended to install a buffer tank in between the filter and the filler. Two options are available: the Atmospheric Tank and the Isobaric Tank. The Atmospheric Tank is a simple solution, 200L in size with internal level sensor and external control for a pump.

$3,999.99

-

EnoItalia Bag In Box Filler | BB50 | Fully Automatic Filling & Conveyor System | 380V Three Phase

Fully automatic operation: BB50 pulls in bag film, fills, cuts bag, and feeds down conveyor belt for packaging Bag valve is automatically removed and reinstalled during the vacuum filling process In addition to wine, it can be configured for olive oil, creams, sauces, soaps, and other industrial liquids Automatic motorized conveyor at end point where bags are dropped through the hopper into boxes Touchscreen control panel installed in stainless steel enclosure on rolling casters The BB50 is a fully automatic bag-in-box filler manufactured by EnoItalia in Italy. The most advanced model of EnoItalia’s bag-in-box fillers, the BB50 automatically feeds bags into its vacuum filling system, cuts and separates the bags, and feeds them down a conveyor for box packaging. The system consists of three modules – the filling machine itself, a stainless steel enclosed control panel, and a motorized roller conveyor where boxes receive the filled bags. The possibility to choose between different types of flow sensors allows the BB30 to be used with liquids of different viscosities, including wine, fruit juices, olive oil and more. Filling can be carried out at room temperature or hot up to 212°F / 100°C. In the case of hot filling, specific accessories are available depending on your set up. A self-priming volumetric pump with rubber impeller is installed as standard. This pump offers a high flow rate, the possibility to prime/draw from any container, an anti-pressure by-pass valve and a total drain valve for emptying the filling circuit. If you will install a filter station before the filler, it is recommended to install a buffer tank in between the filter and the filler. Two options are available: the Atmospheric Tank and the Isobaric Tank. The Atmospheric Tank is a simple solution, 200L in size with internal level sensor and external control for a pump. The Isobaric Tank is a more professional 100L automatic buffer tank that uses nitrogen to push liquid into the filler. With this configuration, the BB50 will not include the pump, and the control panel will have an automatic program to set the pressure used during filling or washing. Precision: The Autotuning function allows automatic calibration of the machinery, eliminating the need to carry out countless samples. Repeatability of volumes with an error of ± 0.2%. Control Panel: The Siemens PLC control panel allows you to manage all the filling phases, adapting the machine to any type of liquid treated (wine, fruit juices, oil, water, creams, etc.). From the touch screen control panel, you can program and manage the filling cycle, adjust working speed, calibrate dosages, and execute washing and sanitizing operations. Cleaning: The machine can be sanitized with a CIP circuit using the special stainless steel tap and the automatic program. Furthermore, the BB50 is designed to perform 230°F / 110°C steam sanitization. Other Advantages: Structural and mechanical components are made completely in AISI 304 stainless steel Equipped with a 9500 L/h self-priming volumetric pump with rubber impeller and speed regulation inverter Possibility to request adapters for countless types of caps and bags (purch, berker, QCS, QCD, etc.) Multilingual display (Italian, English, French, German, Russian, Spanish, Croatian) Components: Siemens PLC panel control w/ 7" touchscreen Remote assistance kit with LAN connection Control panel installed on stainless steel cart with rolling casters, 16' cable connection Automatic separation of bags Self-priming electric pump with rubber impeller - 9,300 L/h, 900 RPM Electronic speed variator for pump Vacuum filling system Continuous filling of bags with VITOP tap (other taps on demand) SS fitting for cleaning circuit (CIP). Automatic program fo cleaning Total drain valve installed on pump body Specs: 1.5" T.C. connection Capacity: 3L bags -- 500 per hour 5L bags -- 480 per hour 10L bags -- 280 per hour 20L bags -- 200 per hour Power: 2.5 HP, 380V, 50hz, three-phase 5 poll Dimensions: 130" x 44" x 99" (3300mm x 1100mm x 2500mm) Weight: 1,433 lbs (650 kg)

$72,999.99

-

EnoItalia Flexible Impeller Pump | Euro 60 | Must Pump | Self-Priming | Remote Control | Stainless Control Box & Trolley Cart | 100 GPM | 3 in. T.C. | 230V

Self-priming must pump with variable flow control from 0 to 100 gallons per minute Flexible rubber impeller gently pushes must and wine Stainless steel pump head with 3" tri-clamp connections Remote control operation with 30 ft. long cord Stainless steel control box Stainless steel rolling cart Made in Italy by EnoItalia This unit features a stainless steel control box not pictured in the primary image. Updated images coming soon. The Euro 60 Flexible Impeller pump is a 3" T.C. self-priming pump with a Stainless Steel head, controlled via a frequency inverter that allows for flow control from 0 - 100 gal / minute. These units can be controlled via the remote control on a 30' cord, or from the control panel mounted on the pump itself. Pumps are reversible, self-priming up to 15', and can be used with wine, juice, or must. The wheeled pump cart allows for easy movement and maneuverability around the winery or crushpad, and stainless steel construction insures that it'll survive through hectic wine seasons! Completely food grade components have no impact on the quality of the wine, and a low shear value due to the larger TC fittings. This pump is a true all around winery pump because it can be used with must and wine. If you have a commercial crush pad with a larger destemmer crusher like a Jolly40 or above, and you process small berries, you will want to consider the Gamma 80 as it works better with dry fruit (lots of skin and not as much flesh). However the Euro60 works well with most musts and then can be your work horse to move must and wine in the winery, making it a great value you can use year around. Although the Euro 60 is self-priming, the pump should never be run dry. Features: Stainless steel head with flexible rubber impeller Gear reduction for increased low speed torque Stainless steel cart Remote control Flow rate from 0 to 100 gpm Flow is reversible Max Pressure: 33 PSI (2.3 BAR) 3" Tri-Clover inlet and outlet 4KW/5.3HP motor Will work with 208v or 230v Single Phase Power 14 amp draw Recommended temperature range: 40 - 150°F (5 - 65°C) Made by Enoitalia of Europe Please note: the unit will arrive with a bare power cord. You will need an electrician to wire the appropriate plug.

$5,499.99

-

Enolmaster Wine Bottle Filler (Vacuum Filler) - 4 Spout - USED REFURBISHED

Used – Refurbished This unit is used. It has been restored to working order. It will have cosmetic defects and show signs of previous use. It is still covered by our No Hassle Return Policy and 1 Year Warranty Policy. A commercial version of the Enolmatic filler that features four filling heads and allows you to fill up to 600 bottles per hour. This is the best bottle filler for the large-scale home winemaker or a small commercial operation. Through the use of a vacuum, the Enolmaster filler automatically starts a siphon, sucks the air out of your wine bottles to preserve freshness, and automatically shuts off when each bottle is filled to the perfect height every time. Not only does the entire process take place in a nearly oxygen-free environment, preserving the freshness of your wine, the rate of fill is extremely fast allowing you to bottle up to 600 bottles per hour. The Enolmaster creates a vacuum that sucks the wine directly from your fermenter, storage tank, or barrel, which can be located up to 12 feet below the Enolmaster. No need to start a siphon or to have to pump or move your wine above your filling machine. The vacuum simultaneously sucks the air out of your bottle allowing you to fill in a nearly oxygen-free bottle. This quality-first process helps to ensure that the delicate flavors of your wine, the flavors you worked so hard to get, are not lost in an open-air bottling process. Additionally, there are no moving parts in contact with the wine ensuring the gentlest handling possible. Fill speed can be adjusted allowing you to bottle at your preferred pace. While the filler is in operation, wine is not allowed back into the storage tank or barrel due to a one-way valve located in the supply line. The small amount of excess wine runs into a collection reservoir. The fill height can be adjusted and can be used with any size or type of bottle. The Enolmaster is a commercial product designed for a small winery. It has a continuous duty cycle, meaning it can run non-stop and is constructed entirely from food-grade materials. The frame is made of stainless steel as are the filling heads. Simply run water through the system to clean out the lines. The reservoir for excess overfill can be rinsed out or ran through the dishwasher. To filter your wine and bottle fill at the same time, add the optional in-line Tandem Professional Filter Housing and Filter Cartridges. Base and frame made from 304 stainless steel Fill nozzels made from 316 stainless steel Fill up to 600 x 750ml bottles per hour Made in Italy by Tenco Dimensions: 650m x 460mm x 450m Weight: 25 kg (55 lbs) Power: 110V / 60hz / 120W Fill bottles from 180 - 350 mm (7" - 13.75") in height Fits bottles with inner neck diameters of 16 - 28 mm (5/8"- 1.1")

$3,299.99 $2,399.99

-

EnoItalia EuroFill 30 Pump | Automatic Dosing System | 0-1,370 GPH | 2.2 kW | 220V

Combines all the benefits and advantages of our best-selling rubber impeller Enoitalia Euro Pumps with inline volume measurement. This is a pump with a brain! Enter in the volume of wine you would like to pump and the EuroFill turns off when that volume has been pumped. With a built-in flow meter, PLC (programmable logic controller) and a touch screen this pump will reduce human error and make your cellar life a lot easier. Filling barrels, blending exact volumes of wine, and dosing larger tanks with specialized ingredients are a few of the most useful applications. You can also control pumping by time which can be useful for pump overs and cleaning solutions. Includes a wireless remote control. Made by Enoitala, a pump specialist, in Tuscany Italy. Sold and supported in the USA by MoreWine!. Unique Applications: Know the volume pump during any transfer Program an exact volume you want pumped Easily create perfect blends Fill barrels by volume (and then top off) Can be used for all general pumping application Features: Rubber impeller pump with electronic speed control Programmable Logic Controller (PLC) for manual or automatic operation Endress induction flow meter Programmable dosing, counting, and timer Remote control 7" Touchscreen Stainless steel control panel and trolley Dry run protection Pressure switch Specifications: Capacity: 0-1,373 GPH (0-5,200 L/h) Max Pressure: 40 PSI (2.8 BAR) 1.5" Tri-Clamp Inlet/Outlet 220V, Single Phase 2.2 kW Please note: the unit will arrive bare without a power cord, plug, or controls to power the motor on or off. You will need an electrician to wire the appropriate power cord and controls to the motor.

$8,799.99

-

Set of Stacking Tanks | Stainless Steel | 1650L & 1400L

In Stock and Ready to Ship! Speidel’s cuboid tanks are the ideal solution for small spaces. They fit perfectly, have curves that are easy to clean and have flawless weld seams. Both tanks have cooling jackets in L51 Layout with C6 Connection. The 1400L tanks has a 0.7 m² jacket and the 1650L has a 1.1 m² jacket. In a few words: our rectangular models are always first choice! They allow you the perfect utilisation of space and guarantee Speidel’s top quality! Enjoy optimal fit with best hygiene and easy cleaning. Standard Accessories: Tank shell and tank bottom made of AISI 304 stainless steel, surface IIId (2R), marbled outside Tank top made of AISI 316 stainless steel, surface IIId (2R), marbled outside With lifting lugs Base tank from 2,000 mm tank height upwards and stacking tank with ladder safety bow Vaulted, stable tank top with moulded-on forward up-slope for complete filling and ventilation assuring a very small air contact area Moulded connection neck with filling and vent neck, 2" T.C. Free-standing base tank on 4 welded-on stacking legs Sampling Weld-on thread NW 10 DIN 11851 with sealing cap (for the installation of sample tap). Manhole Stable manhole neck seamlessly moulded from the tank shell, 420 x 320 mm, door with butterfly bow and hand wheel. Racking Outlet With welded-on reinforcing plate with 2" tri-clamp connection. Fill Level Weld-on thread NW 10 DIN 11851 with sealing cap including fastening points at tank shell (for the installation of fill level indicator). Bottom Outlet Vaulted, stable tank bottom with integrally moulded forward down-slope for complete draining with moulded connection neck, inhibiting suction effect with bottom 2" T.C. outlet.

$18,499.99

-

Speidel Variable Volume Tank | Laser-Welded | Stainless Steel | 1100L

Please note: the primary image is an example image and does not exactly match this tank. See below for features and specifications. Variable capacity tank well-suited for fermentation, wine aging, kombucha, and other applications Floating lid can be positioned as needed to match the volume of the liquid you're working with Proprietary rubber lid gasket allows for a superior seal compared to traditional gaskets, providing better protection for your wine Pulley rope for lowering and lifting the floating lid Made in Germany by Speidel We are proud to present our line of premium quality stainless steel tanks. Built in Germany by Speidel, the world-class traditions of German engineering and craftsmanship are reflected in these tanks. And, after examining tanks built by every major manufacturer worldwide, we can safely say that when it comes to features, quality and price, these tanks represent the very best value available in stainless steel wine storage. Speidel Quality Features: Interior Finish - Speidel tanks feature an ultra-smooth 2R rated interior surface which effectively resists the build-up of tartrate residues. Clean your tanks with cold water after cold stabilization! Say goodbye to harsh cleaning chemicals and expensive CIP systems! Weld Quality - Speidel's robotic-arm laser welders create flawless stainless to stainless junctions that look and feel more like a taped fabric seam than a traditional weld. Ultra high-quality welds leave no chance for residual product to harbor spoilage organisms. Thickness - Speidel tanks are designed to be the correct thickness for the tank's total volume. Complete Drainage Bottoms - All Speidel tanks are outfitted with conical, pocketed bottoms for total drainage, which maximizes product yield at rackings and makes cleaning a snap. *Please note that smaller, flat-bottomed tanks do not feature total drainage bottoms. Tri-Clamp Valve Ferrules - All Speidel tanks come configured for use with Tri-Clamp (TC) style valves and fittings. Tanks up to 1600L capacity are outfitted for use with 1.5in TC. Other sizes and custom configurations are available at additional cost upon request. **Please Note: TC valves not included. Please inquire with your sales associate for pricing on TC valves and fittings. Rubber Lid Gaskets - The white rubber gaskets used by Speidel are much thicker than the traditional clear vinyl gaskets, which along with their extruded manufacturing process provide a much better seal with the tanks wall. They're seamless and more oxygen resistant than the clear gaskets. That means better protection for your wines! Warranty - Speidel-Behaelter, GMBH backs up each and every tank with an industry-leading 25 year warranty against defects in materials or workmanship. And, as a 5th generation manufacturer, you can be confident they'll be around to honor that warranty should the need arise. Tank Features: Volume: Sealed, 1100 L. Open top, 1183 L Variable Capacity Tank includes Floating lid and Heavy Duty White Rubber Gasket Complete Drainage Dish Bottom Lifting Arm Reinforced Racking valve 1.5" TC connections NW10 fitting for use with Sample Valve or Thermometer and Thermowell Combo (Sample Valve or Thermometer and Thermowell not included) Note: Over tightening the airlock / orange bulk head can cause it to crack. Only thread the airlock down until it feels snug. Do not over tighten.

$4,179.99 $2,925.99

-

Five Star | Lactic Acid (88%)

88% concentration. Use to adjust pH of sparge water down.

$220.99