For winemakers dedicated to crafting consistently exceptional wines, precise temperature control during fermentation and storage is paramount. Investing in a complete glycol chilling system offers unparalleled reliability and the ability to independently manage the temperature of your fermentation vessels, storage tanks, and even your cellar – all with a single, efficient unit.

The Science Behind the Chill: How Glycol Systems Work

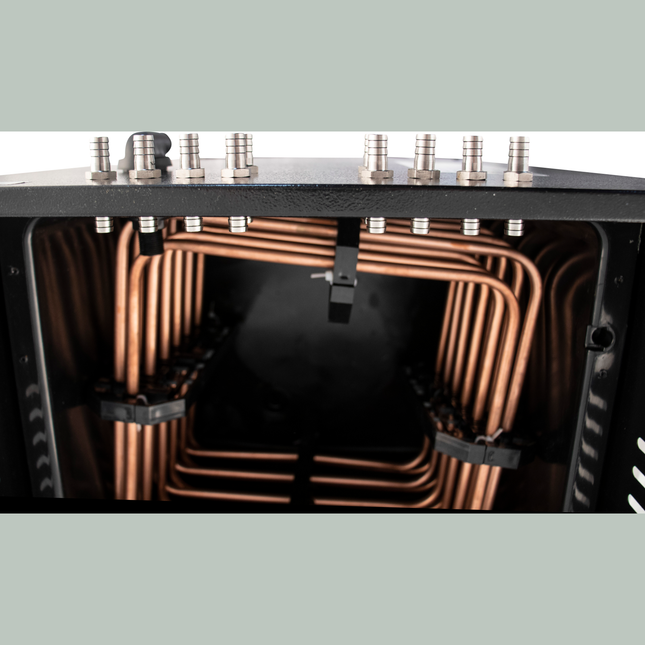

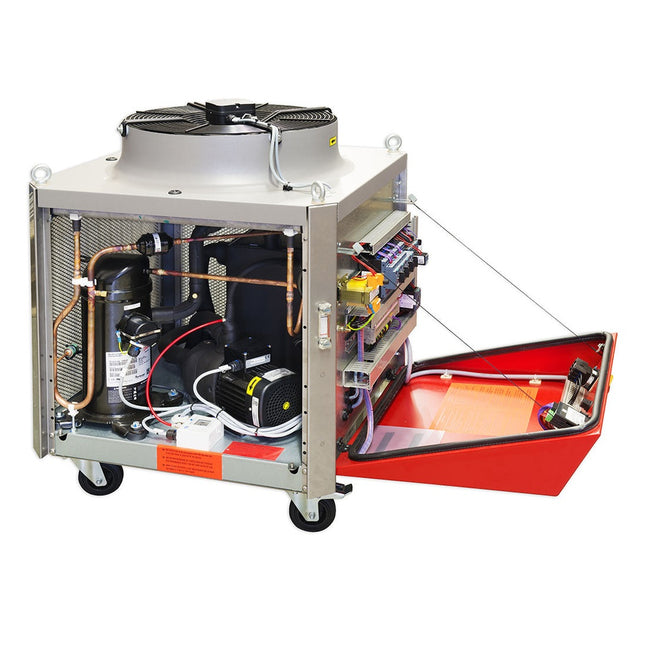

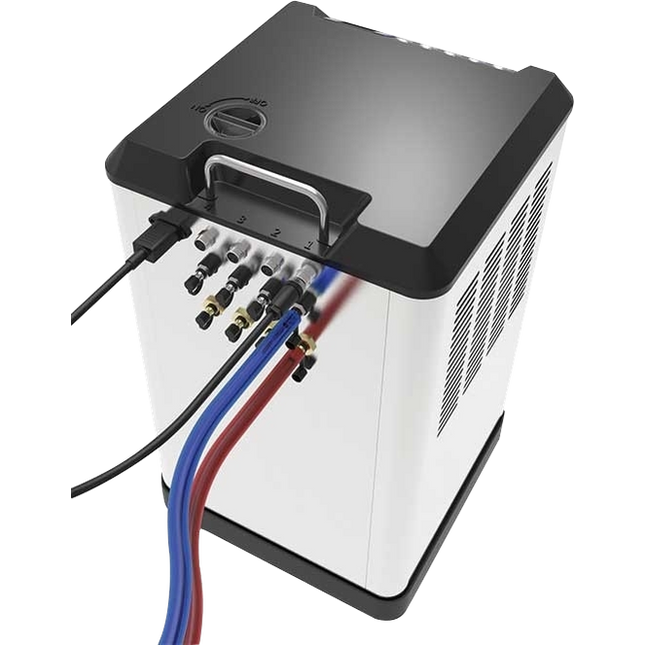

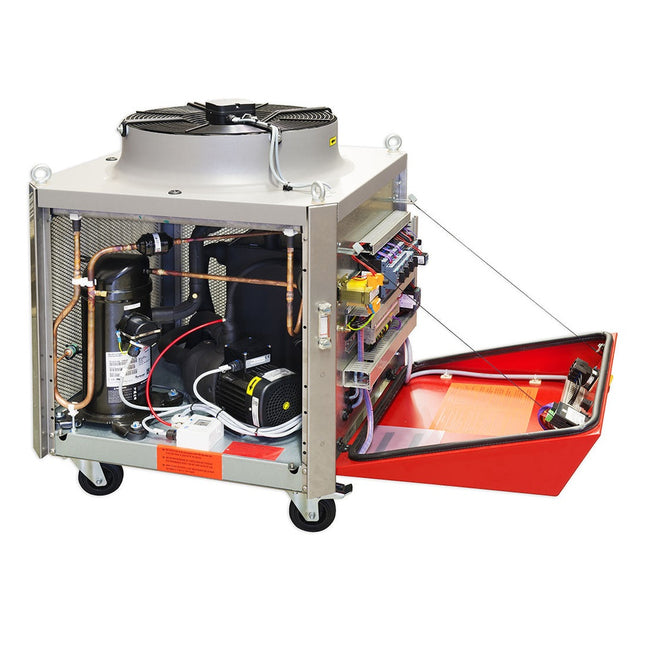

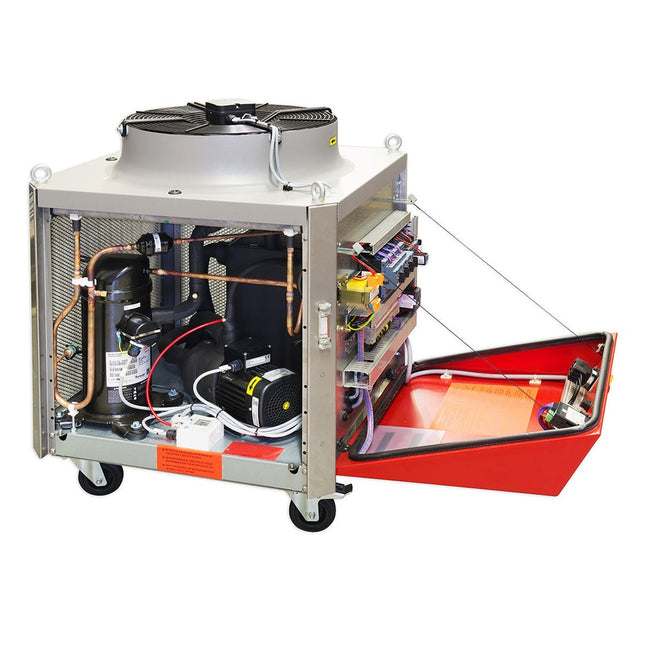

At the core of this technology lies the glycol chiller, a specialized refrigeration system designed to cool a reservoir of propylene glycol, often simply referred to as "glycol." This chilled glycol solution is then circulated through an insulated network of tubing connected to the chiller's inlet and outlet. This forms your primary cooling loop. To cool individual vessels, you simply connect their heat exchangers (such as tank jackets, stainless steel plate exchangers, or stainless steel cooling snakes) to this main loop. Once connected, the chilled glycol flows through the heat exchanger, effectively cooling the wine within the vessel.

Fine-Tuning Your Fermentation: Mastering Temperature Control

Given that glycol is typically chilled below water's freezing point for optimal cooling efficiency, maintaining fermentation temperatures above freezing requires careful management of the glycol flow rate through the heat exchanger. This crucial adjustment can be achieved through two primary methods:

- Manual Regulation: Implementing a shut-off valve allows for manual adjustment of the glycol flow, enabling temperature control. However, this method necessitates consistent monitoring to maintain the desired temperature.

- Automated Precision: The recommended approach for effortless and effective temperature management involves utilizing a temperature-controlled solenoid valve. This system is connected to the tubing leading to the heat exchanger, with a temperature probe placed directly in the wine (often within a thermal well). Simply program your desired wine temperature, and the solenoid valve will automatically open and close as needed to maintain that precise temperature.