Crusher/Destemmers are used to first crush wine grapes and then separate the grapes from the stems. The manual model is appropriate for small lots of grapes, while the motorized versions become a necessity for larger volumes. The machines are made for us in Italy and feature our MoreWine! brand name. We maintain a careful involvement in the manufacturing process. By offering what have historically been our most popular models we are able to stock replacement parts, though in truth we rarely sell any of them!

Crusher Destemmers

-

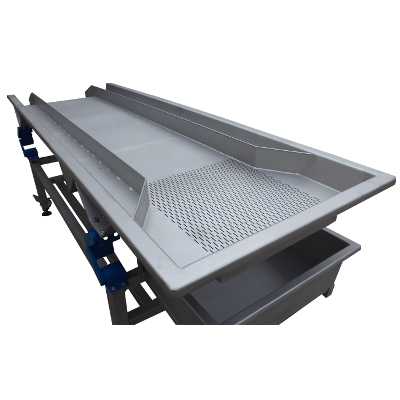

EnoItalia Stainless Stand and Chute

After using the Italian crusher/destemmer units for many years ourselves, we designed and manufactured a special accessory stand that is just tall enough to allow grapes to drop directly into your fermenter or transfer container. Many customers opt to use our 32 Gallon food-grade containers (which we sell as WE509). A regular garbage can can be placed at the end of the unit to collect stems. By using the stand you eliminate the need to move the must and stems from container-to-container, thus saving time and energy. This model fits our WE220 and WE223 series of EnoItalia Crusher/Destemmers. Does not fit models from other manufacturers. Please Note: This stand comes broken down, and will require assembly. Estimated Overall dimensions: Footprint: 32 1/4" long x 22" wide Height: 40" high. Top Tray Inside dimensions 32" long x 14" wide

$384.99

-

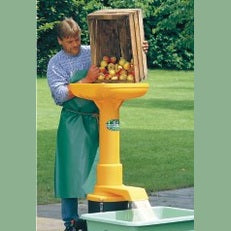

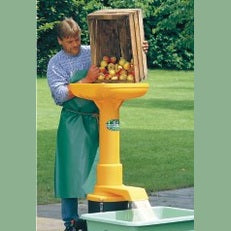

Speidel Motorized Apple & Pear Crusher | Fruit Shredder | Heavy-Duty PE Plastic | Reversible, Stainless Steel Blades | 220V Single Phase

Easy-to-operate, highly-efficient fruit crusher Made from high-quality rust-free materials throughout Optimum milling of apples and pears to provide the highest possible yield when juicing 2,200 lbs per hour processing capacity Stainless steel, re-grindable, reversible, hardened blades Made in Germany by Speidel We have been offering the Speidel Apple & Pear Mill for nearly two decades and it continues to be our most popular crusher year after year. This fruit grinder impresses with its quality, functionality and safety. From the chute to the motor, this unit is made entirely in Germany. The body of the crusher is made from food-safe, high-quality PE plastic that provides extreme durability. The large funnel at the top makes feeding fruit quick and effortless while the integrated roller allows the unit to be moved and transported with ease. Cleanup is as simple as spraying down the funnel and blade assembly with water. The only maintenance the mill needs is occasionally sharpening the grinding blades. Do you want optimum milling for pressing and fermenting your apples and pears for Cider? If so, the Speidel Apple and Pear Mill is just right for you. It shreds apples and pears in an optimum manner; not too coarse, not too fine – exactly the right size of cut to guarantee you the highest possible yield when juicing (without fruit pulp in the juice) as well as speedy fermentation! Simple to Operate The Speidel Apple and Pear Mill is easy to use. Simply plug it in, switch it on and start feeding your apples or pears! It has a large feed-hopper to make it easy to fill in the fruit directly from the box. It can handle up to 2,200lb of fruit per hour. Cleaning is simple: just remove the feed hopper and spray off the appliance and the hopper with water. Maintenance-Free The Speidel Apple and Pear Mill is almost maintenance-free. Only the cutter blades should be sharpened from time to time. Rust-Free for its Service Life Hopper, motor block, cutter blades, apron, feet etc. are all made of high-quality rust-free materials requiring neither care nor any special treatment. No rust even after years of use. Safety is a Top Priority The Speidel Apple and Pear Mill complies with all applicable European Safety Standards (CE Sign). Additionally, the motor is equipped with a thermal overload switch. The feed hopper has both reach-in and switch-on protection. Polyethylene shield to protect the cutters and the motor against any unauthorized intervention and against splashing water. Mills Ready for Pressing & Fermentation No fruit pulp in the pressed fruit juice Highest possible juice yield when pressing Optimal conditions for fast, healthy fermentation Specifications: Feed hopper Made of heavy-duty orange PE plastic (recyclable) Lower part Made of heavy-duty black PE plastic (recyclable) Motor 220V 1-Phase, 50Hz, output 2.2 kW (3HP), speed 2,800 r/min On / Off Switch with lock-out feature Connection 220V, 50Hz Cutting Unit Made of stainless steel, re-grindable, reversible, hardened blades Other Info Up to 2,200lb/hr; Rust-Free; All Parts Food-Safe Height (in) Length (in) Width (in) Discharge Height (in) Weight (lb) 49.2 13.8 30.1 15 55lb Supplied with a 7' power cord. You will need to wire on the correct 220v plug. CE Certified FAQ: How much can be processed with the grinder in what amount of time? The Speidel Apple & Pear Mill can process roughly 2,200 lbs of fruit per hour. Why did the grinder suddenly switch off during operation? Too much fruit has been loaded in, the grinder may be overheating and needs to cool down. Feed fruit more slowly. The funnel is not seated correctly. The switch-on safety device is no longer actuated. Check the fit of the funnel and the setting of the tension locks. Overload on the power line. Check the fuse. What maintenance work must be carried out? The unit is almost maintenance-free. Only the blades should be sharpened from time to time. Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the unit with the appropriate plug.

$1,709.99

-

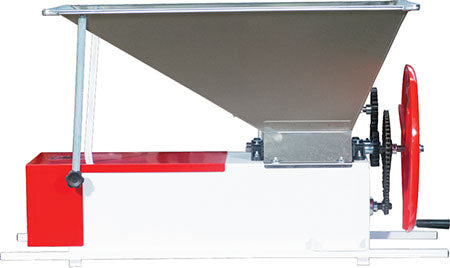

EnoItalia Manual Apple Crusher | Stainless Steel Hopper | Aluminum Rollers

Simple, hand operated crusher for home cider makers 24" x 17" stainless steel hopper Fruit is cut up by knife blades before passing through the aluminum rollers Compact design can sit on top of your fermenter or press Made in Italy by EnoItalia Make your own apple cider with this easy-to-use manual crusher! Put the apples (or pears) into the 24" x 17" hopper and crank away. The knife blades cut the apples and the aluminum rollers grab the apples and pull them in and smash them up yielding a pulp that can then be pressed. Hand operated, place over one of our white fermenters or directly on top of your press.

$429.99

-

EnoItalia Jolly 25 Destemmer | Built-In Must Pump | Stainless Steel | 2 HP | 220V Single Phase

All stainless grape destemmer with built-in must pump Screw Feed provides fast, continual hands-free operation Rubber tipped destemming bar for softer processing 4,000 - 4,500 lbs/per hour processing capacity Removable stainless basket for easy cleaning Made in Italy by EnoItalia For the serious home winemaker or a very small winery, this machine represents an amazing value. It is gentle, easy to load, and pumps the grapes into your awaiting fermenter, eliminating the need for a separate must pump. Why No Crushing Rollers? Because you don't need them. Here is how it works. You put fruit in the top bin and the screw feed moves the fruit to the left where it drops down into the destemming chamber. The fruit is destemmed and grapes drop down through the grate to the next level. Stems are ejected out the end of the destemming chamber and onto a tarp on the ground. After the fruit drops through the destemming chamber it falls into a bin at the bottom of the machine that has a screw feed. The screw feed pushes the grapes to the right where they are pushed into a circular chamber. In the circular chamber, a paddle wheel, pushes grapes back out the exit tube, through a 3" hose, you attach, and into the awaiting fermenters. Why this machine is so popular in Italy Because they know you don't need rollers on this type of machine. The action of the two screws, the destemming chamber and the paddle wheel crack the berries. More on the Built-in Must Pump The built in paddle-wheel style must pump can push fruit an average of 12' high with a 10' horizontal run OR up to 4' high with a 40' horizontal run. These are estimates only: actual results will vary on factors such as the total load on the machine and the viscosity of the must in the transfer tube. It can only be used at processing time and cannot be used later in the winemaking process. A Great Value! We recommend this machine for small wineries or larger home producers who do not wish to make the considerable jump to truly commercial quality equipment. You can make very, very good wine with this machine and we often tell small winery owners that the money saved can be used more effectively in other ways to make great wine. Summary of Features: 1) Stainless Body, Bin, Agitator, and Screw Feed 2) Removable stainless basket for easy cleaning (Destemming basket holes are 1.0225" wide) 3) A Screw Feed for continual, faster, hands-free operation 4) Rubber tipped destemming bar for softer processing 5) Output of 4000 - 4,500 lbs/per hour 6) Paddle wheel style Must pump built in with 3" TC Outlet 7) A powerful Single Phase 220V 2 HP motor (12.1 amp draw) with starting capacitor 8) High-quality units made by Enoitalia of Italy 9) Replacement parts are available 10) Two casters allow for easy wheel-barrow type movement 11) Emergency stop button 12) Length 46.5" (118 cm), Width 27" (68 cm), Height 35.4" (90 cm), weight 207 lb (94 kg) 13) Unit comes with bare cord wire. Wire on the appropriate 220v plug for your electrical connection. Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$3,079.99

-

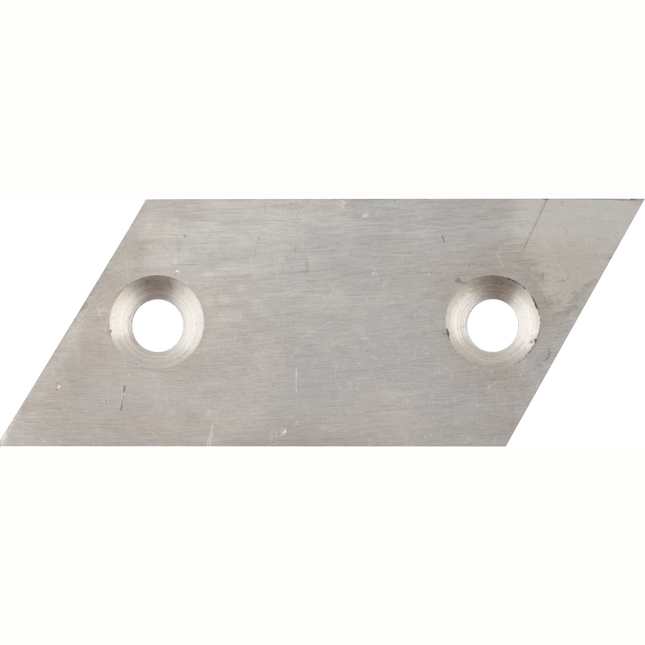

Replacement Shredder for Speidel Motorized Apple & Pear Crusher

Replacement Shredder for Speidel Motorized Apple & Pear Crusher (WE208).

$29.99

-

EnoItalia Motorized Destemmer for Elderberries | Stainless Steel | 110V

Motorized unit separates stems from elderberries Stainless steel construction throughout Screw Feed provides fast, continual hands-free operation 2,500 lbs per hour production capacity Made in Italy by EnoItalia Our #1 selling destemmer. This motorized unit with a stainless screw feed also features a stainless steel Body and Bin making it a completely stainless steel model. This model has been adapted specifically for processing elderberries, which have a smaller diameter than grapes. The destemmer can be purchased by itself or alongside the Stainless Stand & Chute. This stainless steel support stand features a closed bottom hopper that keeps your product contained while dropping into a receiving vessel or pump to move your fruit for further processing. Also compatible with the standard EnoItalia Stainless Stand & Chute if you prefer a three-sided, "open" bottom hopper. How These Work: Elderberries are loaded into the top bin where the powered screw feed continually pushes them towards the destemming chamber. The destemming chamber features a removable basket and rotating destemming shaft. Berries fall through the holes into your bucket. Stems get rotated through the basket by the destemming shaft until they exit at the end of the machine where they fall onto the ground or an awaiting bucket. Output Production Powered by a 1hp motor that provides an hourly production of approximately of up to 2500 lbs. Note that these machines must be fed with consistency to reach maximum throughput. Overload the machine with too many elderberries at one time and the motor will pause and actually slow down production. Cleaning Remove two quick bolts and the safety cover slides off and the internal stainless destemming grate slides out for easy cleaning. The hose out the rest of the unit. Comes with directions. Features: 304-Type Stainless Steel Bin, Body, Screw Feed, and basket A Screw Feed in the Receiving Bin for continual, faster, hands-free operation Solid Construction A powerful 110V 1HP motor which provides an hourly production of approximately 2500 lbs. Replacement parts are available Big, Red Emergency stop button on motor shuts down the machine in a hurry to help reduce chance of accident Overall dimensions: 47.6" long x 23.6" wide x 27.1" high. Weight: 110 pounds (50KG.) Figure 150 lbs for shipping weight with pallet.

$1,449.99 - $1,979.99

-

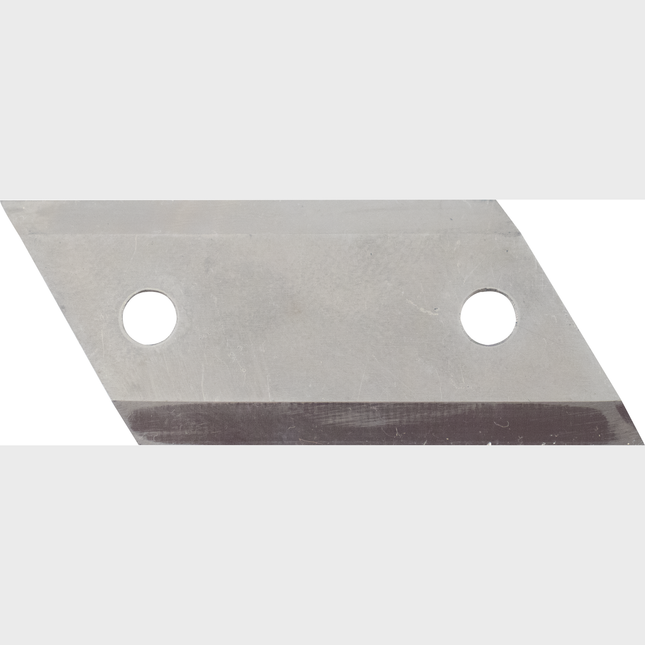

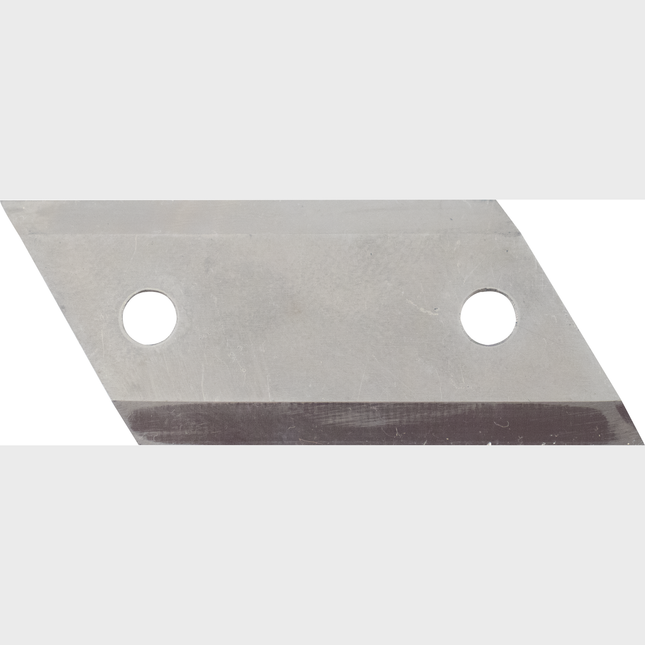

Replacement Blade for Speidel Motorized Apple & Pear Crusher

Replacement Blade for Speidel Motorized Apple & Pear Crusher (WE208) Please note: this is a single blade. Please update your order quantity to the number of replacement blades you require.

$28.99

-

EnoItalia Motorized Apple & Pear Crusher | Fruit Shredder | Stainless Steel | 1.5 HP | 110V

Process apples, pears, and other non-pitted fruit Stainless steel construction throughout Easily disassembles for cleaning after use Made in Italy by EnoItalia A motorized shredder for use with apples, pears or any other fruit which needs processing before it can be pressed for its juice. Not for use with peaches, cherries or other pitted fruits. To use, fruit is fed into the hopper at the top of the machine, where it falls on to spinner cutter blades which shred the fruit. The mash is then pushed out of the machine and into your waiting bucket where it can then be transferred to the press. Extremely simple to operate, and safe since the cutting blades are buried deep in the machine during operation. Sturdy, all stainless steel construction means that you know this machine will last you for years and years. Simple disassembly for cleaning. Runs on standard 110V power with a 1.5HP Motor. We tested this shredder ourselves and found that because it is only 110V, you have to feed the fruit in slowly and consistently. If you have access to 220V power, we recommend our WE208 crusher, which can hold more fruit at once and crush more fruit per hour.

$1,649.99

-

EnoItalia Jolly 60 Destemmer Crusher| Electronic Speed Control | Stainless Steel | 2.5 HP | 230V Single Phase

Variable speed, motorized unit offers a precise level of control when processing grapes Stainless steel construction throughout Centrifugal processing—destemming basket rotates to more efficiently remove stems Rubber coated wiper blade gently pushes grapes to the collection tank Collection tank comes with rolling casters for easy removal 6 tons per hour processing capacity Made in Italy by EnoItalia The bigger brother of our Jolly 40 Destemmer Crusher. The Jolly 60 features some key upgrades over the Jolly40 that allow for even more gentle processing. The Jolly 60 has a higher production, is quick to adjust and even more gentle on your grapes. We suggest you first take the time to read through the Jolly 40. Centrifugal Processing - the Jolly 40 features a non-rotating destemming basket where the grapes fall through and are moved to the collection tank via a stainless screw feed. The Jolly 60 features a basket that also rotates. This design is more effective at removing stems. It also has the benefit of using a spiral, rubber coated wiper blade welded to the basket that more gently pushes destemmed grapes to the collection tank. By comparison the Jolly40 uses a stainless screw under the basket to move grapes to the collection tank. Adjustable Rubber Tipped Destemming Shaft - Instead of rigid paddles on the Jolly40 the Jolly60 features adjustable tips that can help reduce jacks (bits of stems) in certain situations. Additionally the tips are cylindrical instead of paddle shaped. This an option we choose from the manufacturer and is not reflected in the photo. Processing Advantages Vrs. Jolly 40 Rollers slide out of way on stainless rails and do not have be disconnected like on the Jolly40 Collection tank is on casters for easier removal vrs being hard mounted on the Jolly40 50% higher processing capabilities vrs Jolly40 The Collection Tank & Must Pump Choice The collection tank, located at the bottom of the machine, consists of a stainless bin with a stainless auger feed that is driven by the machine. It pushes crushed grapes into your awaiting rubber impeller must pump where the must is moved into your fermenter. Rubber impeller pumps like the Enoitalia EURO 60 must pump will do a good job unless the grapes are dry (high skin, less flesh). The Euro 60 is also a good choice because it has so many other uses in the winery. You can remove the collection tank altogether, allowing the must to drop via gravity, which allows you to do one of two things. First you have the option to wheel in a true commercial quality eliptical must pump, such as the Enotialia Gamma 80, designed for commercial crush pads. Eliptical must pumps are big pumps with 3" outlet tubing that allows for a gentler transfer and are also better for dry (small berry, less flesh) fruit. The Gamma 80 is the smallest version of a true crush pad must pump, perfectly suited for this machine. A second option if you remove the reception hopper is to just allow the fruit to drop via gravity into containers and transfer that manually to macrobins. Of course the latter option is only feasible with a strong back and very small lots, but sometimes that is a nice option to have. Features: 304 Stainless Steel Construction Process up to 6 tons per hour 230V 1 phase 2.5HP Motor Variable Speed with Frequency Drive Slide out of the way Rubber Rollers Rubber Rollers are spring loaded and can be adjusted Rubber Tipped Destemming bars Rubber Edged Auger in Reception Hopper Collection Hopper, with 3" TC outlet, can be removed Centrifugal - Basket rotates Unique basket mounted wiper blade eliminates stainless screw feed Destemming basket features 24mm holes Casters, 2 of which lock Easily removed destemming basket and shaft for easy cleaning Control box can be easily unplugged and removed for wash down Weighs 400 pounds Approximate dimensions of 63"H x 33"W x 51.5"T Unit comes with bare cord wire. Wire on the appropriate 220v plug for your electrical connection 8.1 Amp draw at 230v Manufactured by Enoitalia Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$10,499.99 - $11,999.99

-

EnoItalia Delta Zero | Destoner Pit/Seed Remover & Puree Maker | Stainless Steel | 1,200 lbs/h | 1.5 HP | 220V Single Phase

Eliminate the labor-intensive, time-consuming process of removing pits from stone fruit by hand Remove pits and seeds and break down fruit into a puree in one pass Adjustable inner blades can be fine-tuned to maximize efficiency for the particular fruit you're processing Standard basket is sized for most plums, apricots, and smaller peaches Alternate baskets are available to adapt the unit to other fruits 1,200 lbs per hour processing capacity Made in Italy by EnoItalia Put the Delta Zero to the task and stop removing pits by hand! Working with stone fruit can be a daunting task for any winery, brewery, or cidery simply due to the labor-intensive, time-consuming process of removing the pit from each fruit by hand. The Delta Zero makes this process incredibly easy and efficient, with the ability to process up to 1,200 lbs of fruit per hour. As fruit feeds through the unit, the stone is removed and the fruit is broken down into a puree that is ready to use. Say goodbye to canned purees and extracts! Now you can work with fresh fruit without the headache. The Delta Zero Destoner is made from 304 stainless steel and suitable for most small productions. The machine completely separates the pulp from the inner stone and simultaneously crushes the fruit, creating a final product suitable for fermentation or making fruit juices and jams. Furthermore, the inner blades are adjustable to maximize the efficiency of the particular fruit you are processing. The standard basket has 6 mm diameter holes, which is perfect for most plums, apricots and smaller peaches. Alternate baskets with different hole sizes are also available, allowing it to be used with multiple food products including cherries, plums, apricots, elderberries, aronia, etc. See the chart below basket recommendations. For processing larger stone fruit, such as peaches, we recommend the Delta 1 Destoner Pulper . Features: 304 Stainless Steel Construction 220V / single phase / 1.5 HP Motor 5 amps Internal basket with 6 mm holes for Apricots, Plums and Smaller Peaches Process up to 1,200 lbs per hour Emergency stop and CE electric panel Dimensions: 43.3 "L x 25.6" W x 51.2 "H Weight: 176 lbs Diameter Recommended Use 0.6 mm Berries, apples, pomegranates, strawberries 0.8 mm Berries, apples, pomegranates, strawberries 1.2 mm Tomatoes 1.5 mm Tomatoes 2 mm Olives 3 mm Cherries 6 mm Plums, apricots, small peaches 8 mm Peaches Please note: the unit may come pre-wired with a US-style 110V plug, which will need to removed and re-wired with a 220V plug.

$3,299.99 - $3,629.99

-

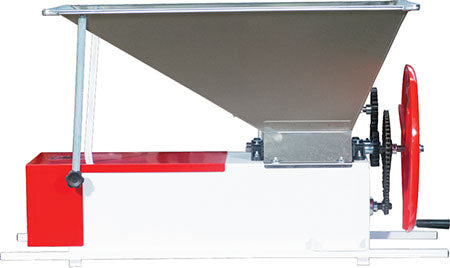

EnoItalia Manual Crusher Destemmer | Stainless Steel Hopper | Nylon Rollers

Hand operated unit crushes grapes and separates stems in one pass Stainless steel basket is removable for easy cleaning Fiber reinforced nylon fly-wheel Nylon rollers Made in Italy by EnoItalia Same unit as our standard Manual Destemmer but with the added longevity of a stainless steel receiving bin. This hand-cranked Crusher/Destemmer is perfect for the home winemaker processing small batches or is working in conjunction with friends who don't mind a little manual work! As the unit is cranked, the grapes are pulled by the agitator into the sturdy nylon rollers where first the grapes are crushed. Next, they fall into the stainless basket where a rotating shaft with paddles separates stems from grapes. The crushed and de-stemmed grapes then fall through the basket while simultaneously the stems are pushed out the end and into a refuse can. All of our units feature removable easy-to-clean stainless grates where the grapes fall through after having been crushed. Imported from Italy from Enoitalia. The Crusher/Destemmer can be purchased by itself or alongside the Stainless Stand & Chute. Features: Stainless Steel Receiving bin Fiber reinforced nylon fly-wheel Stainless Steel Grate that slides out for easy cleaning Sturdy Nylon Rollers Output is speed is as fast as you can crank! Replacement parts are available Product Dimensions 48"Lx27"Hx20"W How to Assemble the Optional Stand & Chute:

$879.99 - $1,159.99

-

EnoItalia Motorized Crusher Destemmer | Stainless Steel | Self-Adjusting Rubber Rollers | 110V

Motorized unit crushes grapes and separates stems in one pass Stainless steel construction throughout Screw Feed provides fast, continual hands-free operation Self-adjusting rubber rollers are soft on grape stems to reduce tannin extraction 3,000 lbs per hour production capacity Made in Italy by EnoItalia Our #1 selling crusher/destemmer style, this motorized unit with a stainless screw feed also features a stainless steel Body and Bin making it a completely stainless steel model. The Crusher/Destemmer can be purchased by itself or alongside the Stainless Stand & Chute. How These Work: Grapes are loaded into the top bin where the powered screw feed continually pushes grapes towards the rollers. Grapes are gently crushed by the rubber rollers and then fall into the destemming chamber. The destemming chamber features a removable basket with a bunch of circular holes in it and rotating destemming shaft. Grapes fall through the holes into your bucket. Stems get rotated through the basket by the destemming shaft until they exit at the end of the machine where they fall onto the ground or an awaiting bucket. Rubber Rollers This model features soft rubber rollers which are softer on stems possibly reducing rough tannins in your wine. The rollers are spring loaded and self adjusting to protect against damage, such as the accidental passing of a small stone. Output Production Powered by a 1hp motor that provides an hourly production of approximately of up to 3000 lbs. Note that these machines must be fed with consistency to reach maximum throughput. Overload the machine with too many grapes at one time and the motor will pause and actually slow down production. Cleaning Remove two quick bolts and the safety cover slides off and the internal stainless destemming grate slides out for easy cleaning. The hose out the rest of the unit. Comes with directions. WE223S Features: 1) 304-Type Stainless Steel Bin, Body, Screw Feed, and basket 2) A Screw Feed in the Receiving Bin for continual, faster, hands-free operation 3) Spring Loaded, Self Adjusting Rubber Rollers 4) Solid Construction 5) A powerful 110V 1HP motor which provides an hourly production of approximately 3000 lbs. 6) Replacement parts are available 7) Big, Red Emergency stop button on motor shuts down the machine in a hurry to help reduce chance of accident Overall dimensions: 47" long x 19.6" wide x 25" high. Weight: 118 pounds (54KG.) Figure 158 lbs for shipping weight with pallet.

$1,759.99 - $2,039.99

-

EnoItalia Motorized Crusher Destemmer | Stainless Steel Hopper | Adjustable Rubber Rollers | 110V

Motorized unit crushes grapes and separates stems in one pass All parts that come into contact with the grapes are made from stainless steel Screw Feed provides fast, continual hands-free operation Self-adjusting rubber rollers are soft on grape stems to reduce tannin extraction 3,000 lbs per hour production capacity Made in Italy by EnoItalia A great value in our motorized Crusher Destemmer line as the parts that are in direct contact with the grapes are stainless while the main body and motor/gear shroud are made from enamel coated steel. Performance is exactly the same as our WE223S Model. The Crusher/Destemmer can be purchased by itself or alongside the Stainless Stand & Chute. How These Work: Grapes are loaded into the top bin where the powered screw feed continually pushes grapes towards the rollers. Grapes are gently crushed by the rubber rollers and then fall into the destemming chamber. The destemming chamber features a removable basket with a bunch of circular holes in it and rotating destemming shaft. Grapes fall through the holes into your bucket. Stems get rotated through the basket by the destemming shaft until they exit at the end of the machine where they fall onto the ground or an awaiting bucket. Rubber Rollers This model features soft rubber rollers which are softer on stems possibly reducing rough tannins in your wine. The rollers are spring loaded and self adjusting to protect against damage, such as the accidental passing of a small stone. Output Production Powered by a 1hp motor that provides an hourly production of approximately of up to 3,000 lbs. Note that these machines must be fed with consistency to reach maximum throughput. Overload the machine with too many grapes at one time and the motor will pause and actually slow down production. Cleaning Remove two quick bolts and the safety cover slides off and the internal stainless destemming grate slides out for easy cleaning. The hose out the rest of the unit. Comes with directions. WE223PS Features: 1) 304-Type Stainless Steel Receiving Bin, Screw Feed, and Destemming Basket 2) A Screw Feed drive receiving bin for continual, faster, hands-free operation 3) Adjustabe Rubber Rollers (adjustment on all small machines, regardless of make, is limited to 5mm because of the way the gears mesh.) 4) Solid Construction 5) A powerful 110V 1HP motor which provides an hourly production of approximately 3000 lbs. 6) Replacement parts are available 7) Big, Red Emergency stop button on motor shuts down the machine in a hurry to help reduce chance of accident Overall dimensions: 47" long x 19.6" wide x 25" high. Weight: 118 pounds (54KG.) Figure 158 lbs for shipping weight with pallet.

$1,429.99 - $1,709.99

-

EnoItalia Manual Crusher Destemmer | Aluminum Rollers

Hand operated unit crushes grapes and separates stems in one pass Stainless steel basket is removable for easy cleaning Fiber reinforced nylon fly-wheel Aluminum rollers Made in Italy by EnoItalia This hand-cranked Crusher/Destemmer is perfect for the home winemaker processing small batches or is working in conjunction with friends who don't mind a little manual work! As the unit is cranked, the grapes are pulled by the agitator into the rollers where first the grapes are crushed. Next, they fall into the stainless basket where a rotating shaft with paddles separates stems from grapes. The crushed and de-stemmed grapes then fall through the basket while simultaneously the stems are pushed out the end and into a refuse can. All of our units feature removable easy-to-clean stainless baskets (grates) where the grapes fall through after having been crushed. The Crusher/Destemmer can be purchased by itself or alongside the Stainless Stand & Chute. Features: Enamel coated body, bin, and agitator 304-Type Stainless Steel Basket (can be removed for easy cleaning) Fiber reinforced nylon fly-wheel Aluminum Rollers Output is speed is as fast as you can crank Replacement parts available Color of enamel may vary Product Dimensions 48"Lx27"Hx20"W How to Assemble the Optional Stand & Chute:

$659.99 - $989.99

-

EnoItalia Jolly 40 Crusher Destemmer | Electronic Speed Control | Stainless Steel | 2.5 HP | 230V Single Phase

Variable speed, motorized unit offers a precise level of control when processing grapes Stainless steel construction throughout Adjustable rubber rollers can be removed in order to destem whole grapes Collection tank with auger feed pushed crushed grapes to an awaiting must pump, or can be removed for gravity feeding 3 tons per hour processing capacity Made in Italy by EnoItalia A great machine for the small winery who is seeking a gentle processing but wants to avoid a high price tag. This is the only machine on the market near this price point that allows you this level of flexibility. The most important feature is variable speed control, via a built in electronic frequency drive, that allows you to slow down or speed up to best adjust the machine to the fruit you are processing. The second key feature is an adjustable rubber roller assembly that can be removed when destemming only is preferred. The reception hopper can be connected to a rubber impeller must pump for an affordable must moving solution or can be removed to allow other ways of moving the must. The Collection Tank The collection tank, located at the bottom of the machine, consists of a stainless bin with a stainless auger feed that is driven by the machine. It pushes crushed grapes into your awaiting rubber impeller must pump where the must is moved into your fermenter. However, you can remove the collection tank altogether, allowing the must to drop via gravity, which allows you to do one of two things. First you have the option to wheel in a true commercial quality eliptical must pump, such as the Enotialia Gamma 80, designed for commercial crush pads. Eliptical must pumps are big pumps with 3" outlet tubing that allows for a gentler transfer and are also better for dry (small berry, less flesh) fruit. The Gamma 80 is the smallest version of a true must pump, perfectly suited for this machine. A second option if you remove the reception hopper is to just allow the fruit to drop via gravity into containers and transfer that manually to macrobins. Of course the latter option is only feasible with a strong back and very small lots, but sometimes that is a nice option to have. The collection tank has a feed outlet on both sides. The side you are not using will need to be capped with a 2.5" end cap, clamp and gasket which are not included. Removable Rollers The rollers can be unbolted and removed from the machine, allowing for destemming only. It is a nice option to have for some fruit types you may choose not to crush. Limitations If you are consistently doing late harvest grapes with dry stems you should choose the Jolly60 over the Jolly 40. If you are running large volumes we really recommend you choose the Jolly 60. The standard basket is not ideal for processing Muscadine grapes. Features: 304 Stainless Steel Construction Process up to 3 tons per hour 230V 1 phase 2.5HP Motor Variable Speed with Frequency Drive Removable Rubber Rollers Rubber Rollers are spring loaded and can be adjusted Rubber Tipped Destemming Paddles 24mm holes in destemming basket Rubber Edged Auger in Reception Hopper Collection Hopper, with 3" TC outlet, can be removed Semi-Centrifugal - Basket does not rotate Casters, 2 of which lock Easily removed destemming basket and shaft for easy cleaning Destemming basket features 24mm holes Weighs 265 pounds Approximate dimensions of 52" x 28" x 53.5" Manufactured by Enoitalia Unit comes with bare cord wire. Wire on the appropriate 220v plug for your electrical connection Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$7,699.99

-

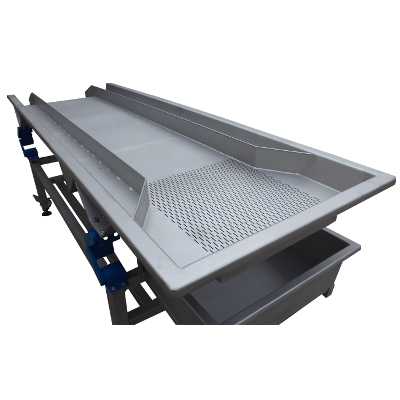

EnoItalia Vibrating Sorting Table | Variable Speed Control | Jolly Reverse Series Crusher Destemmers

Pairs perfectly with the EnoItalia Jolly 60 and Jolly 180 Reverse series crusher destemmers Position the selection table below the Jolly Reverse unit to receive grapes for further sorting and quality control Vibrating action evenly spreads grapes on the table surface for easy visual inspection Raisins, underripe grapes, moldy grapes, etc. are removed by hand so you end up with the best must possible for winemaking Features variable speed control, rolling casters, and height-adjustable legs Vibrating sorting tables are considered the gold standard of sorting, allowing you to make the very highest quality wine from your grapes. They are amazing for removing raisins, underripe grapes, moldy grapes, etc in addition to all MOG (Matter Other than Grapes) such as stems, leaves, and any other foreign material. While they offer the potential of immaculately clean must you do need at least two quick people to work the sorting table. If labor is an issue, consider our Jolly 60 Reverse with Built-in Automatic Sorting Table. While the auto sort will not reach the absolute pinnacle of pristine fruit that a vibrating sorting table with great labor can, great labor is getting harder to find! The Vibrating Selection Table pairs perfectly with the EnoItalia Jolly 60 and Jolly 180 Reverse series crusher destemmers. The table is made entirely of 304 stainless steel with a micro-shot peening surface treatment. Position the table below the Jolly Reverse unit to receive grapes for further sorting and quality control. Grapes drop down onto a slotted area where oxidized juice and seeds are automatically dropped into a collection pan. From there the vibrating action evenly spreads grapes on the table surface for easy visual inspection where moldy, damaged grapes, raisins, stems, leaves or any debris that made it through the destemmer can be removed by hand. The support frame is equipped with 4 swivel casters, telescopic legs that can be adjusted to three different height positions, and 4"-high product containment side rails. The constant advancement of grapes down the sorting table is enabled by the use of two 0.37 kW vibrating motors that cause grapes to 'dance' down the table. The operating portion of the table is 31.5" wide by 10' long. A removable grate complete with DN 50 connection allows the elimination of liquid from the slotted discharge area. As standard, it is supplied complete with a CE-compliant electrical panel and an electronic speed variator. Grapes can either gravity drop off into a waiting collection bin or an optional EnoItalia grape crusher, along with must pump, can be placed at the end of the sorting table. Inquire with our sales staff for more information. Specs: Internal Width: 31.5" Table Length: 10 ft. Capacity: 2-10 ton/h 1.5 kW

$19,499.99 - $21,999.99

-

EnoItalia Screw Elevator U-200 | Variable Speed Control | Loading Hopper | Height-Adjustable Trolley | 220V Single Phase

The U-200 Screw Elevator built entirely in stainless steel, is a multi-purpose machine that allows the transport of whole grapes inside the destemmer, the pomace to the press, or the evacuation of the stems from the unloading area of the destemmer. The low rotation speeds and included speed variator allow non-aggressive handling of the grapes. A height-adjustable stainless steel trolley is supplied as standard. Loading hopper with side pump connection for liquid recovery. 2HP single-phase motor with CE emergency stop. Features: Stainless screw feed 7.8" Diameter x 118" L Variable Speed with Frequency Drive Loading hopper with connection fitting for liquid Open cover lid for cleaning Winch to adjust the height Capacity: 2-10 tons per hour Hopper Dimensions: 25.5" x 28.3" x 35.4" Loading Height: 18.9" to 27.9" Discharge Height: 63" to 78" 220V Single Phase 2HP Motor CE panel control

$9,899.99

-

EnoItalia Jolly 180 Reverse Crusher Destemmer | Electronic Speed Control | Automatic Cleaning System | Stainless Steel | 20 tons/h | 220V 3 Phase

Independently controlled feeding hopper and destemming basket Destemming chamber/basket with anti-tear design is gentle on grapes to reduce skin abrasion Unique chamber-mounted wiper cleanly moves destemmed grapes to the exit 20 tons per hour processing capacity Integrated washing system for quick cleanings between varietals or after an extended break Made in Italy by EnoItalia The Jolly 180 Reverse Destemmer from our partners at EnoItalia features three adjustable speed motors to allow for independent control of the feeding hopper, the destemming process, and the roller group. Along with adjustability in the destemming bar and then on gap setting in the sorting process you can really dial in the machine for your application. Jolly 180 Reverse EnoItalia's newest destemmer, the Jolly 180 Reverse is the ideal processing unit for smaller wineries looking for top-quality processing at an affordable price. The loading hopper features a mechanical speed variable motor so you can control the flow of grape bunches into the destemming chamber. The destemming bar and basket are separately controlled by a variable frequency drive that allows you to turn a dial to set the right speed. Separate control of these processes allows you to find the balance between speed and quality and helps the machine from being overloaded at either stage. The destemming chamber is made with a gentle anti-tear design to reduce grape skin abrasion. The holes in the basket are deep punched through thicker stainless steel, from the inside out, and then bead blasted to remove any sharp edges. The destemming bar features fingers with adjustable rubber tips to ensure a gentle touch on your grapes. The destemming chamber and the destemming bar move in opposite or "reverse" direction for best performance. The receiving hopper features perforated drainage holes to allow juice, sometimes found in the bottom of picking bins, to exit before entering the destemming chamber. There is a 1.5" hose barb for connecting tubing that runs into a collection bucket. That juice is most often discarded. Optional Accessories: The Jolly Reverse can be custom ordered with the below accessories. Contact our Sales Team today to inquire. Collection Tank with Central Screw & Motor - WE540 Larger Hopper for Macrobin use - WE541 Jolly 180 Reverse: 304 Stainless Steel Construction Process up to 20 tons per hour 220V 3 Phase 7HP Motor Variable Speed with Frequency Drive Rubber Tipped Destemming bars Centrifugal Destmming chamber rotates in reverse direction of destemming bar Unique chamber-mounted wiper blade cleanly moves grapes to discharge port Destemming chamber features 24mm holes Casters, 2 of which lock Easily remove destemming chamber/basket and shaft for easy cleaning Unit comes with bare cord wire. Wire on the appropriate 220V plug for your electrical connection Manufactured by EnoItalia Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$24,999.99 - $27,499.99

-

EnoItalia Jolly 60 Reverse Crusher Destemmer | Electronic Speed Control | Automatic Cleaning System | Stainless Steel | 6 tons/h | 220V Single Phase

Independently controlled feeding hopper and destemming chamber Destemming chamber/basket with anti-tear design is gentle on grapes to reduce skin abrasion Unique chamber-mounted wiper cleanly moves destemmed grapes to the exit 6 tons per hour processing capacity Integrated washing system for quick cleanings between varietals or after an extended break Made in Italy by EnoItalia The Jolly 60 Reverse Destemmer from our partners at EnoItalia features three adjustable speed motors to allow for independent control of the feeding hopper, the destemming process, and the roller group. Along with adjustability in the destemming bar and then on gap setting in the sorting process you can really dial in the machine for your application. Jolly 60 Reverse EnoItalia's newest destemmer, the Jolly 60 Reverse is the ideal processing unit for smaller wineries looking for top-quality processing at an affordable price. The loading hopper features a mechanical speed variable motor so you can control the flow of grape bunches into the destemming chamber. The destemming bar and basket are separately controlled by a variable frequency drive that allows you to turn a dial to set the right speed. Separate control of these processes allows you to find the balance between speed and quality and helps the machine from being overloaded at either stage. The destemming chamber is made with a gentle anti-tear design to reduce grape skin abrasion. The holes in the basket are deep punched through thicker stainless steel, from the inside out, and then bead blasted to remove any sharp edges. The destemming bar features fingers with adjustable rubber tips to ensure a gentle touch on your grapes. The destemming chamber and the destemming bar move in opposite or "reverse" direction for best performance. The receiving hopper features perforated drainage holes to allow juice, sometimes found in the bottom of picking bins, to exit before entering the destemming chamber. There is a 1.5" hose barb for connecting tubing that runs into a collection bucket. That juice is most often discarded. Optional Accessories: The Jolly Reverse can be custom ordered with the below accessories. Contact our Sales Team today to inquire. Collection Tank with Central Screw & Motor - WE540 Larger Hopper for Macrobin use - WE541 Jolly 60 Reverse: 304 Stainless Steel Construction Process up to 6 tons per hour 220V Single Phase 3HP Motor Variable Speed with Frequency Drive Rubber Tipped Destemming bars Centrifugal Destmming chamber rotates in reverse direction of destemming bar Unique chamber-mounted wiper blade cleanly moves grapes to discharge port Destemming chamber features 24mm holes Casters, 2 of which lock Easily remove destemming chamber/basket and shaft for easy cleaning Unit comes with bare cord wire. Wire on the appropriate 220V plug for your electrical connection Manufactured by EnoItalia Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$13,499.99 - $13,799.99

-

EnoItalia Jolly 60 Reverse Crush Pad | Auto Sorting | Variable Speed | Stainless Steel | 6 tons/h | 230V 3 Phase

Rolling crush pad with Jolly 60 Reverse Destemmer and automatic sorting table Independently controlled feeding hopper, destemming basket, and sorting table with adjustable speed motors Destemming basket with anti-tear design is gentle on grapes to reduce skin abrasion Unique basket mounted wiper blade eliminates stainless screw feed 6 tons per hour processing capacity Made in Italy by EnoItalia This professional crush pad from our partners at Enoitalia features the Jolly 60 Reverse Destemmer and RBS 60 automatic roller sorting table. Three adjustable speed motors allow for independent control of the feeding hopper, the destemming process, and the sorting table. Along with adjustability in the destemming bar and then on gap setting in the sorting process you can really dial in the machine for your application. Jolly 60 Reverse Enoitalia's newest destemmer, the Jolly 60 is the ideal processing unit for smaller wineries looking for top-quality processing at an affordable price. The loading hopper features a mechanical speed variable motor so you can control the flow of grape bunches into the destemming chamber. The destemming bar and basket are separately controlled by a variable frequency drive that allows you to turn a dial to set the right speed. Separate control of these processes allows you to find the balance between speed and quality and helps the machine from being overloaded at either stage. The destemming basket is made with a gentle anti-tear design to reduce grape skin abrasion. The holes in the basket are deep punched through thicker stainless steel, from the inside out, and then bead blasted to remove any sharp edges. The destemming bar features fingers with adjustable rubber tips to ensure a gentle touch on your grapes. The receiving hopper features perforated drainage holes to allow juice, sometimes found in the bottom of picking bins, to exit before entering the destemming chamber. There is a 1.5" hose barb for connecting tubing. You can either choose to run that juice to a tank, into the Gamma must pump under the destemmer, or into a discard bucket if the juice is too oxidized. Jolly 60 Reverse: 304 Stainless Steel Construction Process up to 6 tons per hour 230V 3 phase 3HP Motor Variable Speed with Frequency Drive Rubber Tipped Destemming bars Centrifugal - Basket rotates Unique basket mounted wiper blade eliminates stainless screw feed Destemming basket features 24mm holes Casters, 2 of which lock Easily removed destemming basket and shaft for easy cleaning Unit comes with bare cord wire. Wire on the appropriate plug for your electrical connection Manufactured by Enoitalia Automatic Sorting Table A great innovation in sorting is the new RBS 60 sorting table, which features adjustable speed and motorized rollers with adjustable gap settings. The idea is that whole berries fall from the Jolly 60 after destemming onto the sorting table. Those berries fall through gaps in the specially designed rollers into either your macrobin or a receiving hopper and must pump. Leaves and pieces of stem, that normally make it into your fermenation tank, are caught on the fingers of the rollers and shot off the end of the table into a garbage bin. The end result is similar to using a vibrating sorting table but the benefit is that the sorting is automatic instead of needing 2-4 people working the vibrating sorting table at all times. If you prefer a vibrating sorting table Enoitalia does make one and we are happy to prepare a custom quote. RBS 60 Automatic Roller Sorting Table Made from stainless steel Adjustable legs Adjustable roller spacing Electronic speed control Please Note: This unit REQUIRES 230V Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord. NOTE: Macro bin shown in example photo is not included with the crush pad. To purchase the macro bin, please see below under "You Might Also Need".

$32,899.99

-

EnoItalia Delta 1 | Destoner Pit/Seed Remover & Puree Maker | Stainless Steel | 2,600 lbs/h | 4 HP | 220V 3 Phase

Eliminate the labor-intensive, time-consuming process of removing pits from stone fruit by hand Remove pits and seeds and break down fruit into a puree in one pass Adjustable inner blades can be fine-tuned to maximize efficiency for the particular fruit you're processing Standard basket is sized for most plums, apricots, and smaller peaches Alternate baskets are available to adapt the unit to other fruits 2,600 lbs per hour processing capacity Made in Italy by EnoItalia Put the Enoitalia Delta 1 Destoner to the task and stop removing pits by hand! Working with stone fruit can be a daunting task for any winery, brewery, or cidery simply due to the labor-intensive, time-consuming process of removing the pit from each fruit by hand. The Delta 1 makes this process incredibly easy and efficient, with the ability to process up to 2,600 lbs of fruit per hour. As fruit feeds through the unit, the stone is removed and the fruit is also broken down into a pulp or juice that is ready to use. Say goodbye to canned purees and extracts! Now you can work with fresh fruit without the headache. The Delta Zero Destoner is made from 304 stainless steel and suitable for most small productions. The machine completely separates the pulp from the inner stone and simultaneously crushes the fruit, creating a final product suitable for fermentation or making fruit juices and jams. Furthermore, the inner blades are adjustable to maximize the efficiency of the particular fruit you are processing. The standard basket has 6 mm diameter holes, which is perfect for most plums, apricots and smaller peaches. Alternate baskets with different hole sizes are also available, allowing it to be used with multiple food products including cherries, plums, apricots, elderberries, aronia, etc. See the chart below basket recommendations. Features: 304 Stainless Steel Construction 220V / 3 phase / 4 HP Motor 13.5 amps Internal basket with 6 mm holes for Apricots, Plums and Smaller Peaches Process up to 2,600 lbs per hour Emergency stop and CE electric panel Dimensions: 55.9"L x 27.6"W x 55.1"H Weight: 330 lbs Diameter Recommended Use 0.6 mm Berries, apples, pomegranates, strawberries 0.8 mm Berries, apples, pomegranates, strawberries 1.2 mm Tomatoes 1.5 mm Tomatoes 2 mm Olives 3 mm Cherries 6 mm Plums, apricots, small peaches 8 mm Peaches Please note: the unit may come pre-wired with a US-style 110V plug, which will need to be removed and re-wired with a 220V plug. Please Note: This unit REQUIRES 220V Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord.

$5,499.99 - $6,049.99

-

EnoItalia Professional Crush Pad | Gamma 180 Elliptical Rotor Pump | Jolly 100 Crusher Destemmer | Loading and Sorting Table

Professional level crush pad featuring the Jolly 100 Crusher Destemmer, Gamma 180 Elliptical Rotor Pump, and Receiving/Sorting/Loading Table Adjustable speed sorting table can accept a macro bin when used with a forklift and bin tipper Jolly 100 with 3 independent variable speed motors offers the highest level of control when processing your grapes Gamma 180 pump gently moves crushed or whole grapes All pieces come with rolling casters for easy mobility Made in Italy by EnoItalia Enoitalia's top of the line complete Crush Pad including the Jolly 100 Crusher Destemmer, a Gamma 180 Elliptical Rotor Pump, and a Sorting and Loading Belt. This system is designed to work together as a complete system with all components able to work within similar and complimentary processing speeds. Enoitalia Receiving/Sorting/Loading Table A very flexible, adjustable speed loading and sorting table that offers multiple benefits. First the large bin is sized to accept a macro bin when used with a forklift and bin tipper. Then the unit uses a sealed food grade plastic belt to consistently and gently move grapes into your Destemmer/Crusher at an adjustable speed you set. This allows you to feed the Destemmer at the optimum rate without overloading it. The flat strectch of the belt allows for a person on each side to sort out leaves, bad bunches, etc.. Adjustable legs allows you to adjust the sorting table to the height of your Destemmer. Designed to feed grapes into the Jolly100. Features: Variable speed via Frequency Drive 1 phase 220 V Stainless Steel Frame 1.5 kW moter 23.6 in Wide (60 cm) 181.1 in Total Length (460 cm) 141.7 in Sorting Length (360 cm) Jolly100 Destemmer & Crusher EnoItalia's top of the line Centrifugal Destemmer Crusher gives you the highest level of control when processing your grapes. It comes with three independent motors allowing you to dial in the perfect speed for your grapes. The loading hopper features mechanically varied motor that allows you to adjust the speed the grapes are being fed into the destemming chamber. The destemming basket and shaft are controlled by frequency drive which allows for the use of potentiometer to electrically control the speed. The rubber rollers are driven by an independant set speed motor and can be adjusted to change the gap, or even removed, if you desire destemmed whole grapes. Independant control of each process allows you to find the balance between speed and quality and helps the machine from being overloaded at any one of the stages. The stainless steel destemming basket is made with a gentle anti-tear design and is driven by rubber tip paddles to ensure a gentle touch on your grapes. The basket has a diameter of 15.75 in (40 cm) and a length 49.2 in (125 cm) and features 24/25mm holes which is the perfect size for a variety of fruit. Baskets with smaller or larger holes are not stocked but are available for special purchase. Enoitalia has tested other basket styles on the market, namely using a plastic basket instead of a stainless basket. Because of they way they punch and finish the holes in the stainless basket they have found there was no difference and the stainless steel lasts much longer. They have also made and tested baskets with variable size holes where the holes begin larger and end smaller with the idea that less jacks will pass. They can make this basket but they actually think it does not work as well. The receiving hopper features drainage holes with allows oxidized juice from the bottom your picking bins to drain. The machine has telescoping adjustable legs that allows the height of the machine to adjust from 60 in/135 cm up to 76 in/193 cm. Cleaning is easy for a machine this size. It features an integrated washing system (connect a garden hose) to help cut down on cleaning time. The top panels, over the destemming chamber, also open up on both sides to allow you to additionally clean with a spray gun. The cleaning system and the easy access are really handy for use between grape varietals, after a break, and at the end of the day when the basket and destemming bar are typically removed for a thorough cleaning. To remove the destemming basket and the bar the whole end of the machine (end with power controls) easily folds up via shocks allowing the destemming shaft and basket to be pulled out without the use of tools. It can be done with one person, however it is much easier with two because of the weight of the basket and bar. Features: Rated for a production between 7-13 Tons per hour Runs on 3 phase 220 V power Loading hopper with gear speed variator kw 0.37 Destemming basket with electronic speed control 2.2/3kw for the shaft and basket Motorized rollers kw 1.5 Destemmer shaft with adjustable rubber tips Stainless steel basket with professional type anti-tear sytem Extraction of the liquid from the hopper with pump fitting connection Rubber screw system n°2 lifting eyes Telescopic legs Integrated washing system Heavy duty bearings with 13 grease fittings for long life Weight: 530 lbs Gamma 180 Elliptical Rotor Pump: Designed to move crushed or whole grapes from the Jolly100 the Gamma 180 is a gentle beast. Made from Stainless steel this elliptical rotor pump is equipped with a large loading hopper and 4" outlet. it is suitable for pumping whole grapes, destemmed, and even fermented grapes during or after fermentation. Grapes are transferred by pressure and not by centrifugal force, avoiding the crushing of the peels and the grapes seeds. The stainless steel trolley with anti-vibration system makes it easy to move and install the machine. As standard it is equipped with an outlet open cone, inclined hopper, and removable control panel. In cases where a prevalence and /or high discharge distance is required, it is advisable to install a compression vessel. As standard, the pumps are supplied with a 4" TC connection fitting, complete with stainless steel hose connection. We don't sell 4" tubing, we recommend you purchase directly from a food grade tubing distributor for the best options and pricing. Features: 4 kw engine 3 phase, 220 V, 60 Hz 12000-15000 kg/hr production Shaft speed: 47/58 rpm 100 DIN connection fitting 5 m discharge height 30 m discharge distance Please Note: This unit REQUIRES 220V Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord.

$43,499.99 - $46,499.99

-

EnoItalia Roll-In Crush Pad Pump | Gamma 80 | Stainless Steel | 16,000 lbs/h | 220V 3 Phase

Wheeled crush pad pump rolls directly under the Jolly 40 or Jolly 60 Crusher Destemmer Stainless steel construction throughout Screw feed moves grapes to the elliptical must pump with 3" tri-clamp outlet Up to 16,000 lbs per hour processing capacity Made in Italy by EnoItalia A 3-Phase Crush Pad Specific must pump that transfers crushed grapes from your Crusher Destemmer to your tank or bin. Entire pump is on wheels and will slide under the Jolly 40 or Jolly 60 Crusher Destemmer. Grapes would fall into the awaiting stainless hopper. Stainless screw moves grapes into the eliptical, paddle style must pump that then moves them through 3" tubing to final destination. Considered more gentle than using a rubber impeller must pump. Only available in 3 phase power. Details: Power: 2.5 HP Three Phase 220 v draws 4.7 amps Capacity: 12,000 to 16,000 pounds per hour Shaft Speed: 47-58RPM Max Pressure: 7.2 PSI (0.5 BAR) Out Let Barb: 3" Tri-Clamp Max Discharge Height: 9 feet Max Discharge Distance: 30 feet Weight: 220 Pounds Pump Body: Stainless Steel Loading Hopper & Screw: Stainless Steel Refillable automatic lubricator Hinged discharge cone can be opened for inspection Single speed pump Please Note: This unit REQUIRES 220V Three Phase power and will not function on anything else. Please confirm that you have the proper power for this unit before purchasing, and plan to have a qualified electrician wire the necessary plug to the cord.

$7,149.99

-

EnoItalia Jolly 100 Reverse Crusher Destemmer | Electronic Speed Control | Automatic Cleaning System | Stainless Steel | 13 tons/h | 220V 3 Phase

Independently controlled feeding hopper and destemming chamber Destemming chamber/basket with anti-tear design is gentle on grapes to reduce skin abrasion Unique chamber-mounted wiper cleanly moves destemmed grapes to the exit 13 tons per hour processing capacity Integrated washing system for quick cleanings between varietals or after an extended break Made in Italy by EnoItalia The Jolly 100 Reverse Destemmer from our partners at EnoItalia features three adjustable speed motors to allow for independent control of the feeding hopper, the destemming process, and the roller group. Along with adjustability in the destemming bar and then on gap setting in the sorting process you can really dial in the machine for your application. Jolly 100 Reverse EnoItalia's newest destemmer, the Jolly 100 Reverse is the ideal processing unit for smaller wineries looking for top-quality processing at an affordable price. The loading hopper features a mechanical speed variable motor so you can control the flow of grape bunches into the destemming chamber. The destemming bar and basket are separately controlled by a variable frequency drive that allows you to turn a dial to set the right speed. Separate control of these processes allows you to find the balance between speed and quality and helps the machine from being overloaded at either stage. The destemming chamber is made with a gentle anti-tear design to reduce grape skin abrasion. The holes in the basket are deep punched through thicker stainless steel, from the inside out, and then bead blasted to remove any sharp edges. The destemming bar features fingers with adjustable rubber tips to ensure a gentle touch on your grapes. The destemming chamber and the destemming bar move in opposite or "reverse" direction for best performance. The receiving hopper features perforated drainage holes to allow juice, sometimes found in the bottom of picking bins, to exit before entering the destemming chamber. There is a 1.5" hose barb for connecting tubing that runs into a collection bucket. That juice is most often discarded. Optional Accessories: The Jolly Reverse can be custom ordered with the below accessories. Contact our Sales Team today to inquire. Collection Tank with Central Screw & Motor - WE540 Larger Hopper for Macrobin use - WE541 Jolly 100 Reverse: 304 Stainless Steel Construction Process up to 13 tons per hour 220V 3 Phase 4HP Motor Variable Speed with Frequency Drive Rubber Tipped Destemming bars Centrifugal Destmming chamber rotates in reverse direction of destemming bar Unique chamber-mounted wiper blade cleanly moves grapes to discharge port Destemming chamber features 24mm holes Casters, 2 of which lock Easily remove destemming chamber/basket and shaft for easy cleaning Unit comes with bare cord wire. Wire on the appropriate 220V plug for your electrical connection Manufactured by EnoItalia Please Note: This item may come with a bare cord or with a European style plug. You will need a professional electrician to wire the pump with the appropriate plug.

$16,999.99 - $17,099.99